Vacuum Packaging Machine For Food - Chinese Manufacturer, Factory, Supplier

In the contemporary exigencies of food conservation and distribution, the imperative to extend the longevity and maintain the pristine quality of comestibles is paramount. A cornerstone of modern food preservation techniques lies in the utilization of the Vacuum Packaging Machine For Food, an ingenious apparatus designed to evacuate atmospheric gases from packaging prior to hermetic sealing. This process, by removing oxygen, significantly inhibits the proliferation of spoilage-inducing microorganisms, retards oxidative rancidity, and mitigates moisture loss, thereby substantially prolonging the shelf life of a diverse array of victuals.

The operational principle of a Vacuum Packaging Machine For Food is elegantly straightforward yet profoundly efficacious. The device typically employs a vacuum pump to create a negative pressure environment within a specialized pouch or container, effectively drawing out the ambient air. Following the attainment of the desired vacuum level, a heat-sealing mechanism is activated, creating an impermeable barrier that prevents the ingress of atmospheric gases and contaminants. This hermetic seal is critical in maintaining the integrity of the vacuum and ensuring the extended preservation of the enclosed foodstuff.

A panoply of Vacuum Packaging Machine For Food models exists, each tailored to specific applications and production volumes. From compact, benchtop units ideal for small-scale operations or domestic use to high-throughput, automated systems designed for industrial processing, the versatility of this technology is undeniable. Chamber vacuum sealers, external vacuum sealers, and even specialized thermoforming packaging machines all fall under this rubric, offering solutions for diverse packaging needs and product types, ranging from delicate perishables to robust cuts of meat.

Within the global manufacturing landscape, china Vacuum Packaging Machine For Food producers have emerged as significant contributors to the availability and affordability of this crucial technology. These manufacturers offer a wide spectrum of machines, catering to both domestic and international markets. While considerations of quality and adherence to international standards are paramount, the proliferation of Chinese-made vacuum packaging equipment has democratized access to this preservation method for businesses of all sizes.

The adoption of a Vacuum Packaging Machine For Food offers a multitude of benefits. Beyond the obvious extension of shelf life, it also aids in preventing freezer burn, preserving the flavor and aroma profiles of food, and even enhancing the visual appeal of packaged products. For businesses, this translates to reduced food waste, expanded distribution possibilities, and ultimately, a more sustainable and profitable operation. In conclusion, the strategic deployment of vacuum sealing technology represents a prudent investment for anyone seeking to safeguard the quality and longevity of their culinary provisions.

Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Fried Food Deoiling Machine

Fried Food Deoiling Machine Vacuum Meat Tumbler

Vacuum Meat Tumbler Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler Vacuum Quantitative Filling Machine

Vacuum Quantitative Filling Machine Vacuum Stuffing Machine

Vacuum Stuffing Machine Gizzard Peeling Machine

Gizzard Peeling Machine Kimchi Production Line

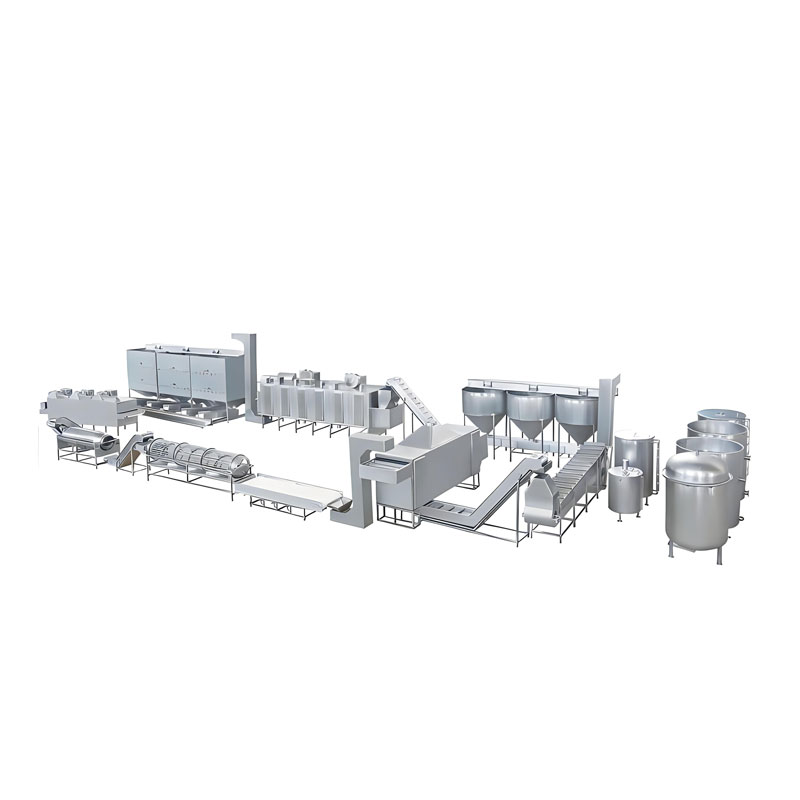

Kimchi Production Line Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment Frozen Meat Slicer

Frozen Meat Slicer Fish Cutting Machine

Fish Cutting Machine Rotary Drum Potato Chips Seasoning Machine

Rotary Drum Potato Chips Seasoning Machine Automatic Dumpling Making Machine

Automatic Dumpling Making Machine