Tomato Sauce Processing Machine - Chinese Manufacturer, Factory, Supplier

The Tomato Sauce Processing Machine is an indispensable piece of equipment for modern food production facilities, where efficiency, quality, and scalability are crucial. It represents a leap forward in food processing technology, offering manufacturers the ability to transform fresh tomatoes into rich, flavorful sauces with unmatched consistency. As the demand for tomato-based products continues to soar, the machine’s role in streamlining production becomes ever more essential.

From the moment the tomatoes enter the machine, every stage of the process is carefully controlled. The initial washing phase ensures that the tomatoes are free from dirt and contaminants, making them safe for consumption. The crushing mechanism then breaks down the tomatoes, separating the juice from the pulp, while the Tomato Sauce Processing Machine simultaneously eliminates unwanted seeds and skins. This level of precision ensures a smooth, high-quality product that retains the authentic taste and natural nutrients of the tomatoes.

Beyond just creating a superior sauce, the Tomato Sauce Processing Machine is built with flexibility in mind. With customizable settings, producers can adjust the machine to create a variety of products, from chunky salsas and marinara sauces to finely pureed tomato pastes. This adaptability is especially important in an increasingly competitive market, where consumer preferences for texture and flavor can vary widely.

In addition to improving product quality, this advanced machine significantly boosts production efficiency. The automated systems reduce the need for manual labor, cutting down on human error and increasing throughput. The energy-efficient design of the Tomato Sauce Processing Machine helps manufacturers keep operating costs in check while contributing to sustainability efforts by minimizing waste and energy consumption.

The machine's robust construction ensures longevity, even under continuous use, making it a wise investment for both large-scale factories and smaller producers seeking to expand their operations. Whether you're producing organic sauces or traditional tomato products, the Tomato Sauce Processing Machine provides the necessary tools to maintain the highest standards of quality and efficiency. By incorporating this cutting-edge technology into your production line, you can enhance both your product offering and your competitive edge in the tomato sauce market.

Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Sauce Filling Machine

Sauce Filling Machine Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Tomato Paste Production Line

Tomato Paste Production Line Automatic Sausage Peeling Machine

Automatic Sausage Peeling Machine Fish Scaler Machine

Fish Scaler Machine Rotary Drum Potato Chips Seasoning Machine

Rotary Drum Potato Chips Seasoning Machine Automatic Banana Chips Production Line

Automatic Banana Chips Production Line Small Chicken Feet PeelingMachine

Small Chicken Feet PeelingMachine Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Gas Shawarma Machine

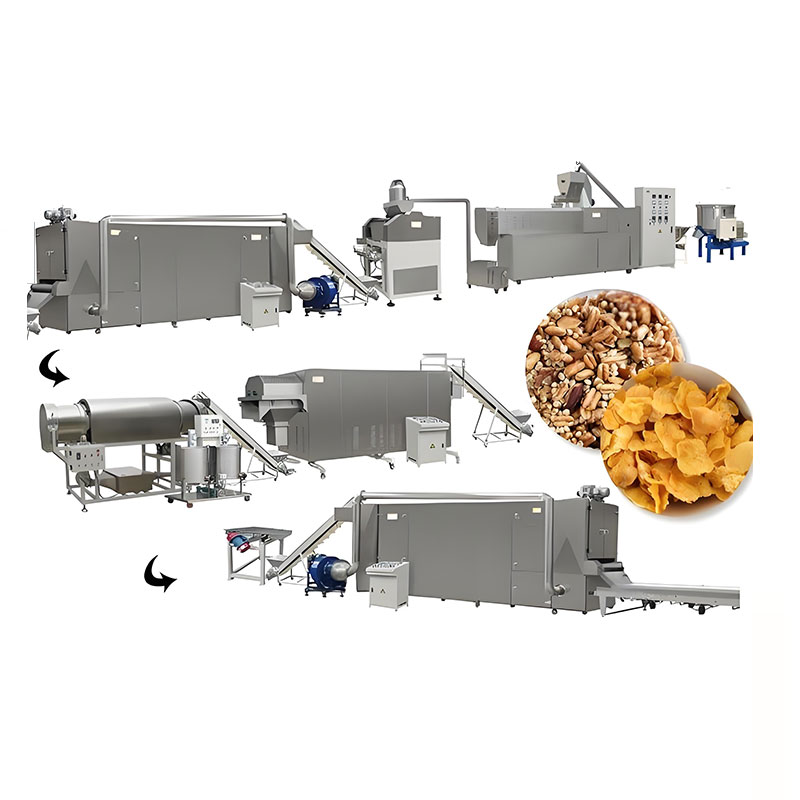

Gas Shawarma Machine Corn Flakes Food Production Line

Corn Flakes Food Production Line