Stainless Steel Meat Slicer - Chinese Manufacturer, Factory, Supplier

A stainless steel meat slicer is an indispensable professional tool for the catering, food processing, and fresh retail industries. Its efficiency, durability, and hygiene features make it a core instrument in commercial kitchens and meat processing operations. This article will analyze its advantages and value across product characteristics, application scenarios, and purchasing considerations.

1. Material Superiority: Food Safety and Durability

The stainless steel meat slicer excels due to its full stainless steel construction (typically food-grade stainless steel 304 or 316 ). This material offers corrosion resistance, ease of cleaning, and high-temperature tolerance, complying with global food safety standards. It effectively prevents bacterial growth, ensuring hygienic meat processing. The robust stainless steel structure withstands frequent use and heavy-duty cutting, extending equipment lifespan and reducing long-term operational costs.

2. Functional Design: Precision Cutting and Operational Safety

Modern stainless steel meat slicers feature precision-engineered blades that allow adjustable slicing thickness (ranging from 0.5mm to 20mm ). This versatility accommodates diverse needs, such as thin deli slices, thick meat cuts, or frozen food processing. Ergonomic handles and non-slip feed trays enhance user convenience and safety, reducing operator fatigue. Some models include emergency stop buttons and automatic power-off safeguards , minimizing accidents and ensuring reliability in high-volume commercial environments.

3. Easy Cleaning and Low-Maintenance Design

The seamless stainless steel design and removable components (e.g., blades, feed trays) enable quick and thorough cleaning. Most models support water or disinfectant cleaning , aligning with commercial kitchen hygiene regulations and reducing cross-contamination risks. Advanced models incorporate quiet motors and low-maintenance frameworks , further streamlining daily operations and boosting efficiency.

4. Applications and Purchasing Guidelines

Stainless steel meat slicers are widely used in hotels, supermarkets, delis, and foodservice chains for slicing processed meats, fresh meats, cheeses, ham, and frozen products. Key considerations when selecting a slicer include:

- Capacity and Power : Choose sizes based on daily throughput (e.g., compact for small-scale operations or industrial models for high-volume needs).

- Additional Features : Look for optional accessories like automatic meat rollers , temperature controls, or digital displays .

- Brand and After-Sales Support : Prioritize brands offering long-term warranties and localized service to ensure long-term reliability.

5. Sustainability and Energy Efficiency

The durable stainless steel construction reduces waste from frequent replacements, aligning with eco-friendly practices. Some brands now integrate energy-efficient motors , lowering power consumption and supporting businesses’ sustainability goals.

Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Electric Cooked Meat Slicer

Electric Cooked Meat Slicer Frozen Meat Slicer

Frozen Meat Slicer Blast Freezer

Blast Freezer Membrane Skinner

Membrane Skinner Automatic Bone Crushing Machine

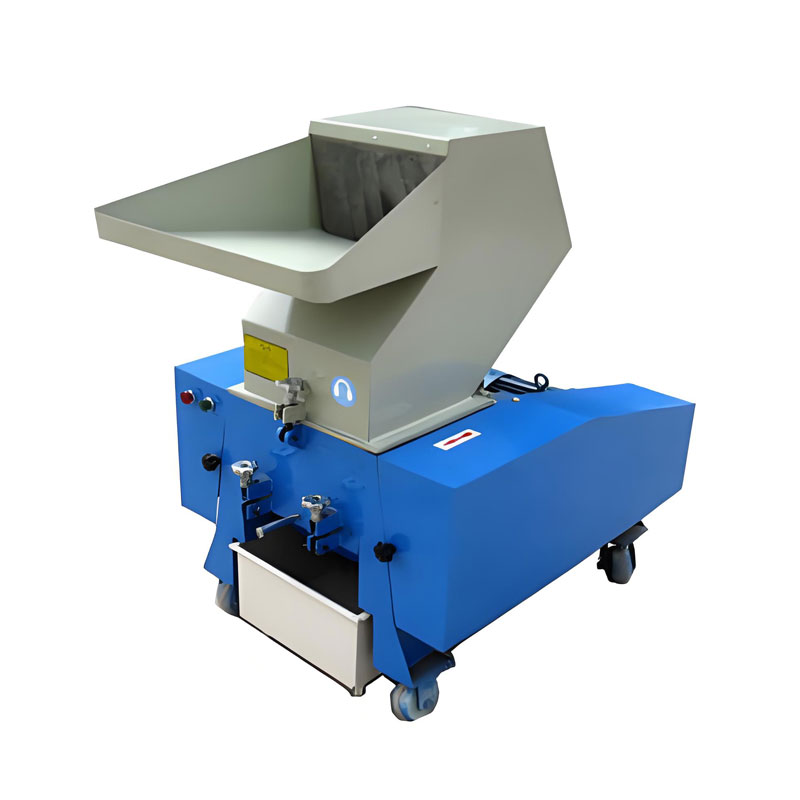

Automatic Bone Crushing Machine Automatic Banana Chips Production Line

Automatic Banana Chips Production Line Brush Potato Washing Peeling Machine

Brush Potato Washing Peeling Machine Gizzard Defatter

Gizzard Defatter Automatic Meat Mixer Machine

Automatic Meat Mixer Machine Automatic Sardine Canning Line Equipment

Automatic Sardine Canning Line Equipment