Poultry Meat Processing Equipment - Chinese Manufacturer, Factory, Supplier

The poultry meat processing industry is a cornerstone of global food production, demanding precision, efficiency, and adherence to stringent quality standards. Central to this operation is the deployment of advanced poultry meat processing equipment, which plays a pivotal role in transforming raw poultry into market-ready products. From slaughtering and evisceration to cutting, deboning, and packaging, each stage requires specialized machinery designed to optimize output while maintaining hygiene and consistency.

Modern poultry meat processing equipment is engineered to handle high volumes with minimal waste, ensuring that every part of the bird is utilized effectively. Automated systems, such as pluckers, eviscerators, and portioning machines, streamline the process, reducing labor costs and enhancing throughput. These machines are often equipped with cutting-edge technologies like IoT-enabled sensors and AI-driven analytics, which monitor performance in real-time and predict maintenance needs, thereby minimizing downtime.

One of the critical aspects of poultry processing is the ability to maintain product integrity. Equipment such as chillers and freezers ensure that meat is rapidly cooled to safe temperatures, preserving freshness and extending shelf life. Additionally, precision cutting tools, like automated deboners and slicers, deliver uniform portions that meet consumer expectations and regulatory standards.

Choosing the right Meat Equipment Suppliers is paramount to achieving operational excellence. Reputable suppliers offer not only state-of-the-art machinery but also comprehensive support, including installation, training, and after-sales service. Their expertise ensures that processors can navigate the complexities of poultry production, from scaling operations to complying with food safety regulations.

In conclusion, investing in advanced poultry meat processing equipment is essential for any operation aiming to thrive in today’s competitive market. By partnering with reliable Meat Equipment Suppliers, businesses can enhance efficiency, reduce waste, and deliver high-quality products that meet the demands of discerning consumers.

Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Frozen Food Production Line

Frozen Food Production Line SF Series Snowflake Ice Machine

SF Series Snowflake Ice Machine YL-W-05 Commercial Water Purification Equipment

YL-W-05 Commercial Water Purification Equipment Fish Meal Production Line

Fish Meal Production Line Multifunction Pasta Machine

Multifunction Pasta Machine Jelly Candy Production Line

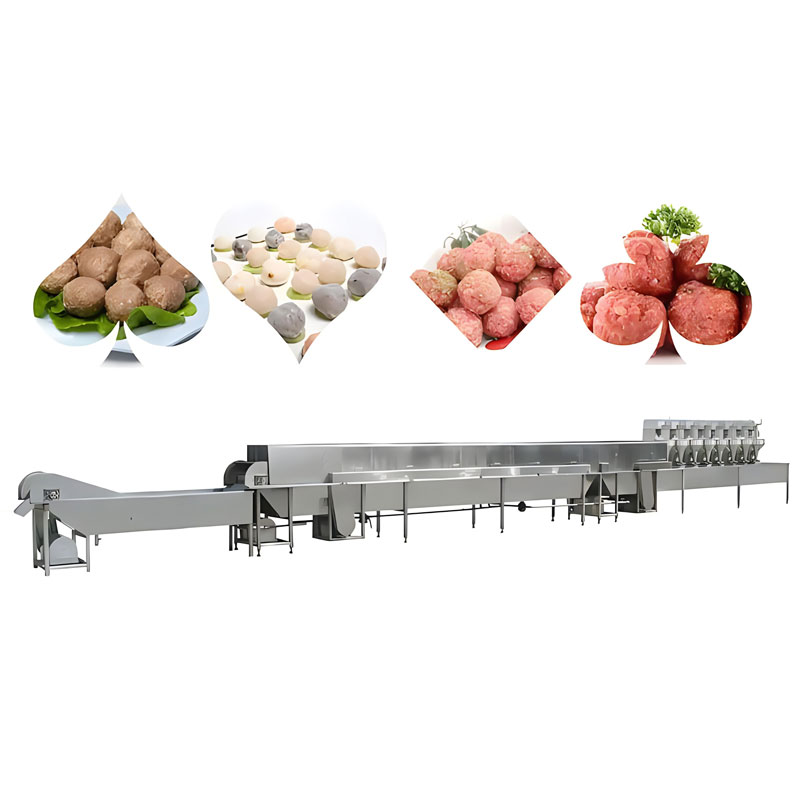

Jelly Candy Production Line Meatball Production Line

Meatball Production Line Brush Potato Washing Peeling Machine

Brush Potato Washing Peeling Machine