Meat Vacuum Tumbler - Chinese Manufacturer, Factory, Supplier

In the pursuit of exceptional meat products, achieving deep flavor penetration and optimal tenderness represents a significant challenge. Traditional marination techniques often fall short, providing only superficial treatment. Enter the sophisticated solution employed by discerning processors: the Meat Vacuum Tumbler. This specialized apparatus is far more than a mere mixing drum; it is a cornerstone technology for enhancing meat quality on multiple fronts, fundamentally altering texture and taste profiles through controlled environmental manipulation.

The operational principle of a Meat Vacuum Tumbler leverages physics to achieve superior results unattainable through static soaking or simple agitation. By creating a vacuum within the rotating drum, atmospheric pressure is significantly reduced. This environmental shift causes the meat fibers to expand, effectively opening up interstitial spaces within the muscle tissue. Concurrently, the gentle yet persistent tumbling action massages the meat. This mechanical agitation, combined with the vacuum-induced expansion, facilitates an accelerated diffusion of marinades, brines, or curing solutions deep into the product core. The hydrodynamic forces generated ensure remarkably even distribution, eliminating the inconsistencies often found with passive methods.

The benefits imparted by this process are substantial and highly desirable for any quality-focused operation. Firstly, the vacuum environment enhances the extraction of myofibrillar proteins to the surface. These proteins become tacky, improving the binding capacity of the meat, which is particularly crucial for formed products and leads to significantly increased cook yields through superior moisture retention. Secondly, the physical action tenderizes the product by gently disrupting muscle fibers, resulting in a noticeably improved mouthfeel. Flavor infusion becomes profound rather than peripheral, ensuring every bite delivers the intended taste profile. Furthermore, the entire process dramatically curtails marination times, shrinking protracted soaking periods from days or hours down to mere minutes or hours, boosting operational efficiency and throughput considerably.

From large-scale industrial meat processors crafting value-added products to smaller artisanal butcher shops seeking a competitive edge through enhanced quality, the utility of the Meat Vacuum Tumbler is undeniable. It represents a strategic investment in product consistency, sensory appeal, and processing efficiency. By harnessing the power of vacuum and mechanical action, this equipment unlocks a higher echelon of meat preparation, ensuring products that are not only flavorful but also exceptionally tender and succulent, ultimately driving customer satisfaction and loyalty. It is an indispensable tool for elevating the standard of processed meats.

Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Vacuum Meat Tumbler

Vacuum Meat Tumbler Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler Vacuum Quantitative Filling Machine

Vacuum Quantitative Filling Machine Vacuum Stuffing Machine

Vacuum Stuffing Machine Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment Dough Kneader Machine

Dough Kneader Machine Hydraulic Sausage Stuffer

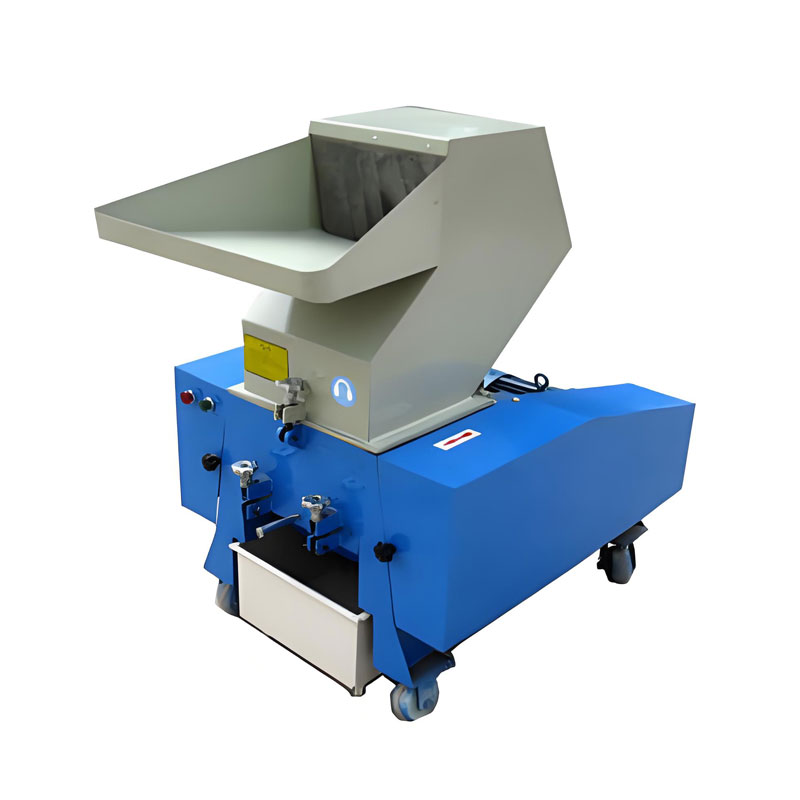

Hydraulic Sausage Stuffer Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Automatic Meat Mixer Machine

Automatic Meat Mixer Machine Rotary Drum Potato Chips Seasoning Machine

Rotary Drum Potato Chips Seasoning Machine Flake Ice Machine

Flake Ice Machine Smoked Furnace

Smoked Furnace