Meat Slicer Machine China - Chinese Manufacturer, Factory, Supplier

In recent years, the demand for efficient and reliable meat slicer machines has surged globally, with many businesses and households turning to Meat Slicer Machine China for cost-effective, high-performance solutions. As a hub of manufacturing excellence, China has emerged as a key player in the production of these essential tools. Known for its innovative designs, competitive pricing, and advanced technology, Meat Slicer Machine China has become a go-to option for industries ranging from food processing to hospitality.

Chinese manufacturers offer a wide array of meat slicer machines, catering to both commercial and residential needs. The versatility of these machines is one of their key selling points. Whether slicing delicate prosciutto for a gourmet restaurant or preparing bulk quantities of meat for a deli, the adaptability of Meat Slicer Machine China ensures that users can achieve precise cuts with minimal effort. With adjustable blade settings, these machines provide the flexibility needed for a range of meat types and thicknesses, making them indispensable in the food industry.

The cost-effectiveness of sourcing a Meat Slicer Machine China is another compelling reason for its growing popularity. Chinese manufacturers are able to produce machines at scale, passing on the savings to consumers without compromising quality. However, the value proposition extends beyond mere affordability. Chinese meat slicers are equipped with advanced features, such as powerful motors, stainless-steel blades, and automated systems, which ensure longevity and superior performance.

Quality control is paramount in Chinese manufacturing, and Meat Slicer Machine China is no exception. Many manufacturers adhere to strict international standards, ensuring that their products meet or exceed the requirements of foreign markets. The incorporation of cutting-edge technology, such as digital controls and enhanced safety mechanisms, further elevates the standard of these machines. For businesses looking to streamline their operations, investing in a Meat Slicer Machine China offers a seamless blend of reliability and innovation.

Despite the numerous advantages, it’s essential to conduct due diligence when sourcing meat slicers from China. Not all manufacturers offer the same level of craftsmanship or customer support. Thorough research, including checking certifications and reading customer reviews, can help ensure the machine purchased meets the required standards for performance and safety.

Ultimately, the rise of Meat Slicer Machine China reflects the country’s ongoing commitment to providing high-quality, affordable solutions that meet the evolving needs of global consumers.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

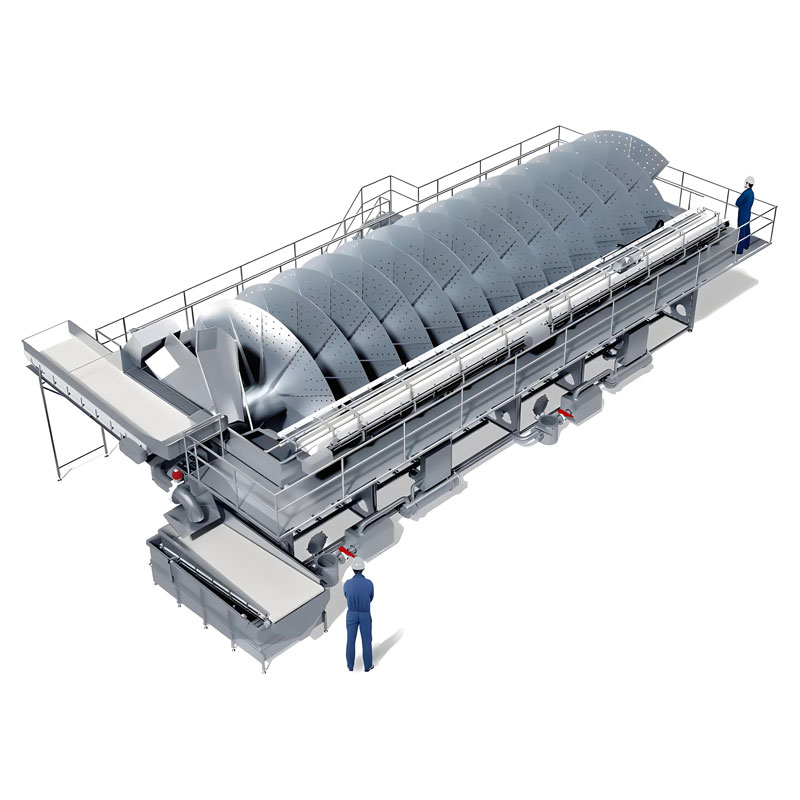

Automatic Meat Tumbling Machine Salmon Processing Line

Salmon Processing Line Microwave Pigskin Puffing Machine

Microwave Pigskin Puffing Machine Model 200 Frequency Conversion High Speed Chopper

Model 200 Frequency Conversion High Speed Chopper Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Shrimp Canning Line Equipment

Shrimp Canning Line Equipment  Gas Shawarma Machine

Gas Shawarma Machine Automatic Meat Mixer Machine

Automatic Meat Mixer Machine Sausage Tying Machine

Sausage Tying Machine