Meat Shredding Equipment - Chinese Manufacturer, Factory, Supplier

Meat shredding equipment is a specialized industrial machinery designed to break down large cuts of meat into fine, uniform strips or particles efficiently. These machines are essential for food processing plants, meat manufacturers, and large-scale operations, enabling the production of minced meat, meat-based fillings, jerky, and other meat products with precision and consistency. Their versatility and high-capacity processing capabilities make them indispensable for meeting the demands of commercial and industrial meat production.

Key Features and Functional Benefits

Meat shredding equipment combines robust engineering with advanced shredding mechanisms to ensure high productivity and food safety:

- High-Capacity Processing :

- Motor power ranges from 2–15 HP , with capacities of 50–1,000 kg/hour , depending on the model.

- Adjustable shredding plates or blades allow customization of meat texture (e.g., fine for patties, coarse for soups).

- Precision and Uniformity :

- Rotating blades or drum systems ensure even shredding, minimizing waste and ensuring consistent product quality.

- Some models integrate temperature control to preserve meat freshness by preventing overheating.

- Safety and Hygiene :

- Constructed from stainless steel , these machines resist corrosion and simplify cleaning to meet FDA and HACCP standards.

- Safety guards , emergency stop buttons , and interlock mechanisms reduce operational risks.

- Versatility :

- Process raw, cooked, or frozen meat (beef, pork, poultry, or lamb).

- Some models accommodate non-meat ingredients like vegetables or spices for fillings.

Design and Operational Efficiency

Modern shredding equipment emphasizes durability and user-friendliness:

Modular Components : Detachable blades and grinders simplify cleaning and maintenance.

Easy Loading/Unloading : Wide feed openings and tilt mechanisms streamline material handling.

Noise Reduction : Insulated casings minimize noise pollution in industrial settings.

Automation Options : Some systems integrate conveyor belts or automatic feeding for seamless production lines.

Applications Across Industries

- Meat Processing Plants :

- Mass production of minced meat for burgers, sausages, or ready-to-eat products.

- Shredding cooked meat for soups, stews, or meat-based sauces.

- Food Manufacturing :

- Producing meat fillings for dumplings, spring rolls, or meat snacks.

- Processing jerky or dried meat strips for packaged goods.

- Restaurants and Catering :

- Preparing bulk shredded meat for tacos, stir-fries, or salads.

- Specialty Markets :

- Custom shredding for halal, organic, or plant-based meat alternatives.

Maintenance and Long-Term Value

To ensure longevity and optimal performance:

Regular Cleaning : Follow CIP (Clean-in-Place) protocols to prevent bacterial growth.

Blade Maintenance : Sharpen or replace blades periodically to maintain precision and reduce energy consumption.

Lubrication : Keep moving parts lubricated to minimize wear and tear.

Choose Durable Models : Opt for anti-corrosion coatings and reinforced bearings to reduce downtime.

Choosing the Right Equipment

Key considerations for buyers include:

Capacity : Match daily production needs (e.g., 100 kg/hour for small plants vs. 1,000 kg/hour for large-scale facilities).

Adjustability : Ensure the machine offers customizable shredding settings.

Certifications : Look for CE , ISO , or HACCP compliance for food safety assurance.

Automation Level : Select manual, semi-automatic, or fully automatic systems based on budget and workflow.

Brand Support : Partner with manufacturers offering spare parts and technical training.

Conclusion

Meat shredding equipment is a cornerstone of modern food processing, enabling businesses to achieve scalability, consistency, and compliance with food safety standards. By prioritizing durability, precision, and ease of maintenance, these machines are critical for producing high-quality meat products efficiently, from small-scale kitchens to large industrial facilities.

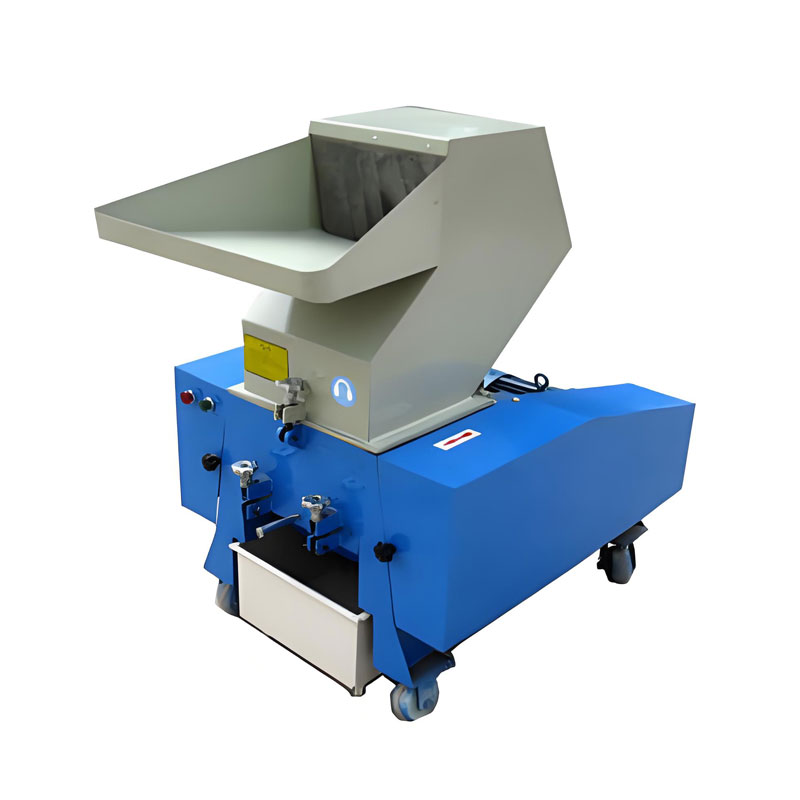

Meat Shredding Machine

Meat Shredding Machine Cooking Drying Oven

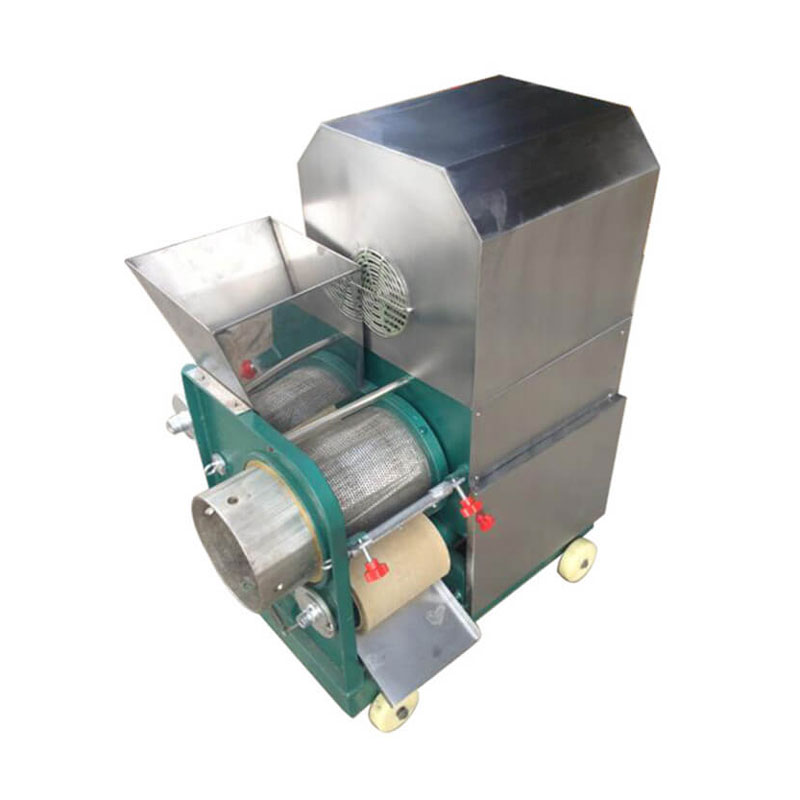

Cooking Drying Oven Cooked Meat Shredder Machine

Cooked Meat Shredder Machine Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Automatic Sausage Clipper Machine

Automatic Sausage Clipper Machine Tofu Production Line

Tofu Production Line Fish Speed Cleaning Machine

Fish Speed Cleaning Machine Vacuum Meat Tumbler

Vacuum Meat Tumbler Fish Deboner Machine

Fish Deboner Machine