Meat Saw Machine Price - Chinese Manufacturer, Factory, Supplier

Meat Saw Machine Price varies significantly depending on factors like size, automation, and manufacturer reputation. For businesses seeking optimal value without compromising quality, understanding these dynamics is key. Among the global suppliers shaping this market, China Yuanlin Factory stands out as a leader in delivering high-performance machinery at competitive prices. Let’s explore how to navigate this landscape and secure the best investment for your operation.

Precision meat processing demands machinery that balances power and accuracy. Meat Saw Machine Price points often hinge on blade technology, motor capacity, and durability. Entry-level models may suffice for small-scale operations, but mid-range and industrial-grade machines offer superior returns through faster throughput and minimal downtime. However, cost alone shouldn’t dictate your choice—longevity and compliance with food safety standards are equally critical.

China Yuanlin Factory , renowned for its precision engineering, offers a range of meat saws tailored to diverse needs. Their machines integrate advanced features such as diamond-tipped blades and anti-vibration systems, ensuring clean cuts even in high-volume environments. What sets them apart is their focus on Meat Saw Machine Price transparency. Unlike brands that inflate costs through middlemen, they streamline procurement, passing savings directly to clients.

Consider the technical specifications: a standard circular meat saw from China Yuanlin Factory might include a 3-horsepower motor and a stainless-steel frame resistant to corrosion. These details reduce maintenance expenses over time, offsetting initial outlays. Meanwhile, their band saw models feature adjustable tension systems, ideal for cutting through dense or fatty tissues without blade slippage—a common issue with cheaper alternatives.

When comparing global suppliers, China Yuanlin Factory ’s edge lies in their vertically integrated production. By controlling every stage from raw material sourcing to assembly, they maintain rigorous quality checks while keeping Meat Saw Machine Price competitive. This approach contrasts with manufacturers who outsource components, risking inconsistencies in performance.

Another advantage is their commitment to sustainability. Modern meat processing prioritizes energy efficiency, and China Yuanlin Factory ’s machines boast low power consumption without sacrificing speed. This aligns with global trends toward eco-friendly practices, enhancing a business’s reputation while reducing operational costs.

Hidden costs often plague unprepared buyers. Shipping, installation, and training can inflate expenses, but China Yuanlin Factory mitigates these through inclusive pricing models. Their packages frequently include technical support and warranty coverage, ensuring a seamless transition for new users.

For instance, a poultry processor in Southeast Asia recently upgraded to a China Yuanlin Factory circular saw, slashing labor hours by 40% and reducing waste by optimizing cut consistency. Such real-world success stories underscore the brand’s reliability.

In evaluating Meat Saw Machine Price , prioritize ROI over upfront costs. A well-engineered machine from China Yuanlin Factory may cost 15–20% more than generic models but lasts twice as long and requires fewer repairs. This calculus becomes clearer when factoring in productivity gains and reduced scrap rates.

The global meat processing industry is evolving, driven by automation and precision. China Yuanlin Factory stays ahead by innovating—recent releases include AI-driven saws that adjust blade speed based on meat density. These advancements position them as pioneers, not just suppliers.

In conclusion, navigating Meat Saw Machine Price requires discernment. Partnering with China Yuanlin Factory ensures access to cutting-edge technology, transparent pricing, and a commitment to your operational success. Investing in quality today safeguards efficiency, profitability, and growth for years to come.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Frozen Meat Grinder

Frozen Meat Grinder Hydraulic Sausage Filling Machine

Hydraulic Sausage Filling Machine Cooking Drying Oven

Cooking Drying Oven French Fries Frying Machine

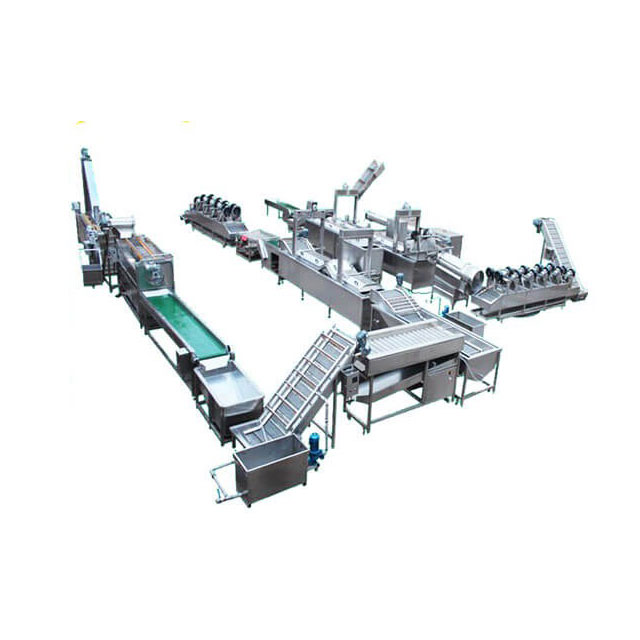

French Fries Frying Machine Frozen French Fries Production Line

Frozen French Fries Production Line Automatic Meat Mixer Machine

Automatic Meat Mixer Machine