Meat Mincing Machine Price - Chinese Manufacturer, Factory, Supplier

Embarking on the quest to acquire a meat mincing machine unveils a spectrum of options, each accompanied by a corresponding Meat Mincing Machine Price point. For the uninitiated, this fiscal landscape might appear somewhat labyrinthine. However, understanding the core determinants influencing cost can illuminate the optimal pathway to a purchase that aligns with both your culinary aspirations and budgetary considerations.

The primary bifurcation in pricing stems from the fundamental dichotomy of manual versus electric models. Manual mincers, often characterized by their robust simplicity and reliance on kinetic energy, typically reside on the more accessible end of the price continuum. These stalwart devices, requiring a modicum of elbow grease, present an economical entry point for those with infrequent mincing needs or a penchant for a more hands-on approach. Conversely, electric meat mincers, with their integrated motors and automated operation, command a higher pecuniary outlay. This premium reflects their enhanced efficiency, ability to process larger volumes with alacrity, and often, a broader array of functionalities such as sausage stuffing attachments.

Another significant factor influencing the Meat Mincing Machine Price is the material composition and build quality of the apparatus. Mincers constructed from high-grade stainless steel, renowned for its durability and resistance to corrosion, will invariably carry a higher tag than those employing less resilient alloys. Investing in superior materials often translates to a longer lifespan and sustained performance, mitigating the need for premature replacement. Furthermore, the puissance of the motor in electric models directly correlates with pricing. More powerful motors, capable of effortlessly grinding tougher cuts of meat, naturally incur a greater manufacturing cost, which is subsequently reflected in the retail price.

Venturing into the realm of manufacturing origins can also provide insights into price variations. While globalization has blurred some traditional demarcations, it is often observed that machinery emanating from certain regions may present differing price structures. For example, businesses such as the yuanlin Meat Mincer Machine factory contribute to the global supply chain, and their pricing strategies are influenced by factors inherent to their operational context. Diligent comparative analysis, encompassing not only price but also verified user reviews and material specifications, remains crucial for informed decision-making.

Ultimately, the optimal Meat Mincing Machine Price is a subjective metric, intrinsically linked to an individual's specific requirements, frequency of use, and desired features. By meticulously evaluating these variables and conducting thorough due diligence, prospective buyers can confidently navigate the market and procure a meat mincing machine that represents not merely an expense, but a valuable and enduring addition to their culinary arsenal.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Stuffed Meatball Machine

Stuffed Meatball Machine Crushed Ice Machine

Crushed Ice Machine Automatic Dumpling Making Machine

Automatic Dumpling Making Machine Fish Meal Production Line

Fish Meal Production Line Gizzard Defatter

Gizzard Defatter Potato Chips Instant Freezer

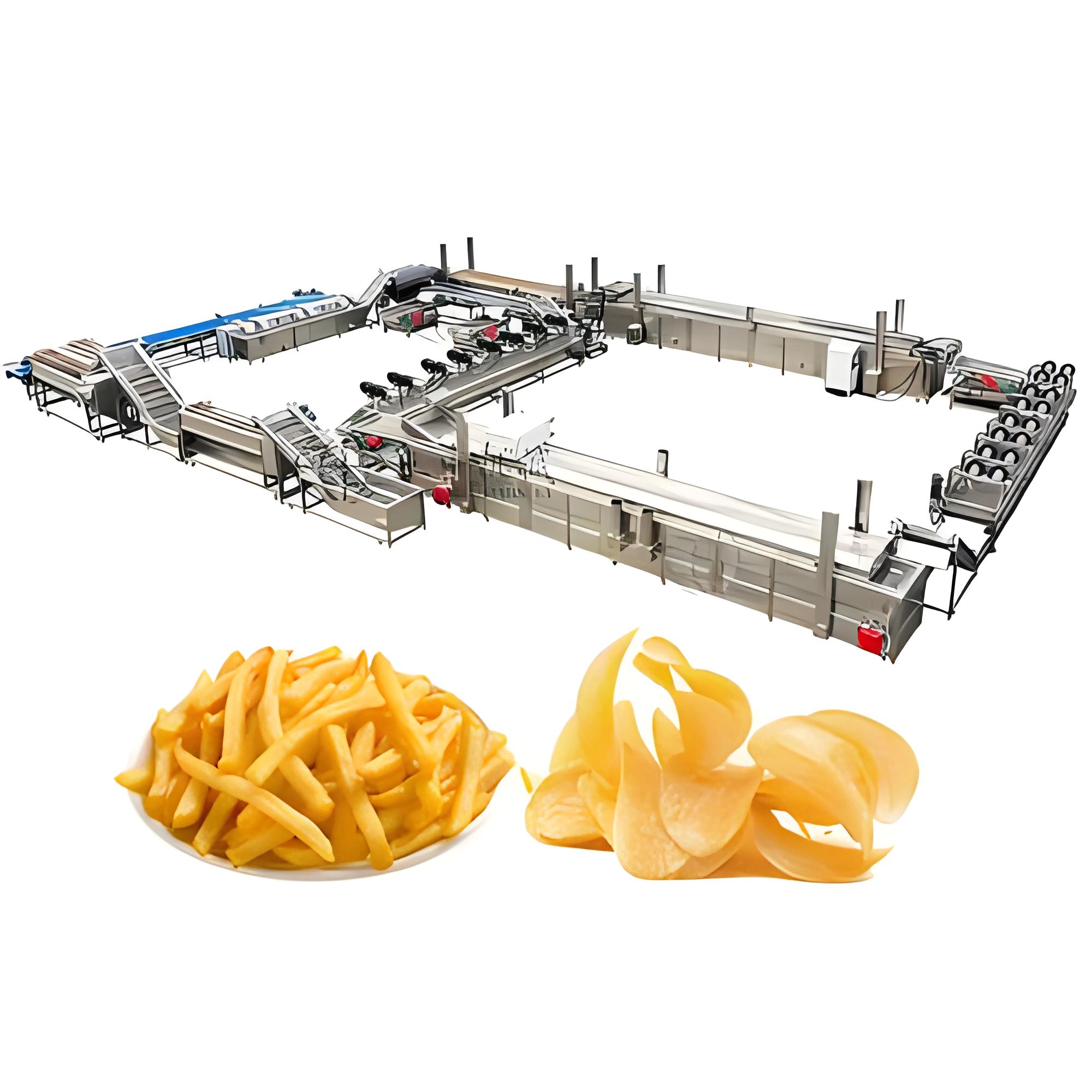

Potato Chips Instant Freezer French Fries Production Line

French Fries Production Line Brush Potato Washing Peeling Machine

Brush Potato Washing Peeling Machine