Meat Equipment Company - Chinese Manufacturer, Factory, Supplier

When selecting the right tools and machinery for meat processing, a reputable Meat Equipment Company is an indispensable partner in ensuring the smooth operation of a production facility. A Meat Equipment Company provides not only the machines necessary for various stages of meat processing but also offers expert guidance on selecting, operating, and maintaining these systems. The equipment they provide is designed to meet stringent food safety standards while optimizing efficiency, durability, and ease of use.

A leading Meat Equipment Company offers a diverse range of machinery suited for different meat processing tasks, including cutting, grinding, slicing, and packaging. Their offerings typically include advanced machines such as high-performance band saws, meat slicers, grinders, and tenderizers. These machines are engineered to meet the needs of both small-scale butcheries and large, industrial processing plants. The versatility of the equipment ensures that the meat processing operation is equipped to handle varying volumes and different types of meat, from poultry to beef and pork.

One of the most significant advantages of working with a well-established Meat Equipment Company is the ability to receive custom solutions tailored to specific operational requirements. A reputable company will work closely with customers to understand their production goals, space limitations, and budget, offering machines that integrate seamlessly into the existing workflow. Moreover, custom designs can help optimize productivity by ensuring that equipment is correctly sized and functions in harmony with other machinery on the production line.

Reliability is another key factor when choosing a Meat Equipment Company. The machinery provided must operate efficiently and consistently under demanding conditions. Equipment failure can lead to costly downtime, safety concerns, and decreased product quality. A trusted Meat Equipment Company will offer high-quality, durable machines made from materials such as stainless steel, which are resistant to corrosion and easy to maintain. This ensures that the equipment performs well over time, with minimal maintenance and repair requirements.

Additionally, a leading Meat Equipment Company often provides comprehensive support services, including installation, training, and ongoing maintenance. This ensures that employees are properly trained to operate the machinery safely and effectively. Moreover, most companies offer extended warranties and readily available spare parts, providing peace of mind to clients regarding long-term operation.

Choosing the right Meat Equipment Company is essential for any meat processing business. The right equipment enhances productivity, reduces waste, and ensures compliance with food safety regulations. Whether upgrading existing machinery or starting a new operation, working with a reputable company ensures the successful and efficient processing of high-quality meat products.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Stuffed Meatball Machine

Stuffed Meatball Machine Pizza Cone Equipment

Pizza Cone Equipment 250kg/Hr Compound Potato Chips Frying Plant

250kg/Hr Compound Potato Chips Frying Plant Automatic Twisting Quantitative Sausage Stuffer Machine

Automatic Twisting Quantitative Sausage Stuffer Machine Fish Deboner Machine

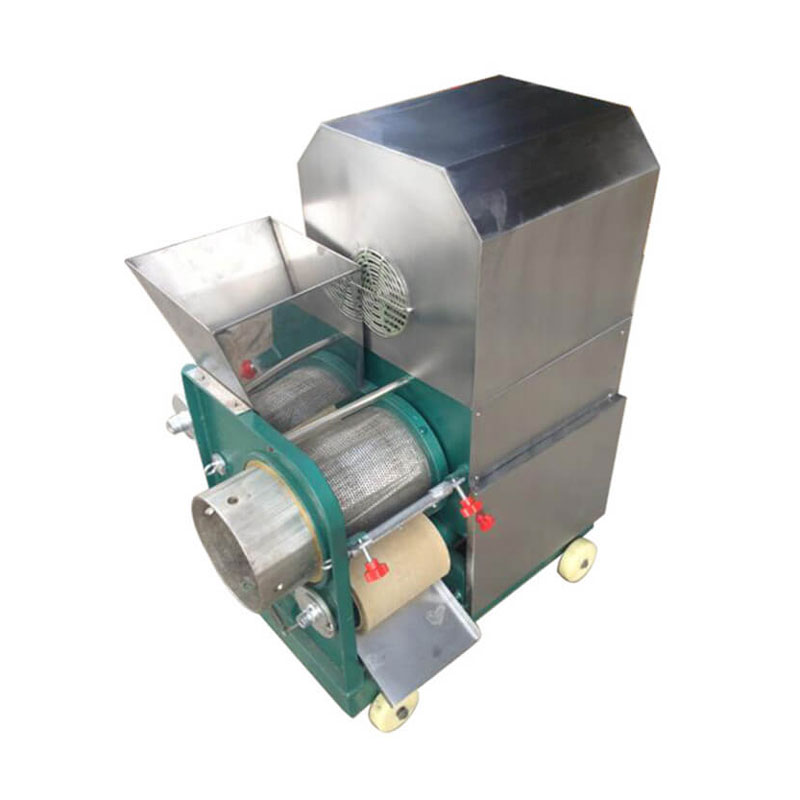

Fish Deboner Machine Gas Shawarma Machine

Gas Shawarma Machine Quail Egg Processing Line

Quail Egg Processing Line Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine Gizzard Peeling Machine

Gizzard Peeling Machine