Meat Equipment China - Chinese Manufacturer, Factory, Supplier

As the global demand for high-quality meat products surges, the role of advanced processing machinery has become indispensable. At the forefront of this technological revolution is Meat Equipment China, a sector synonymous with precision, affordability, and cutting-edge innovation. Chinese manufacturers, such as the renowned China yuanlin factory, are redefining industry standards by blending traditional expertise with avant-garde engineering solutions.

The meat processing landscape demands equipment that ensures hygiene, speed, and consistency. Here, Meat Equipment China excels, offering everything from automated deboning systems to smart packaging units. These machines incorporate mechatronic systems and AI-driven diagnostics, enabling producers to minimize waste while maximizing output. The China yuanlin factory, for instance, has pioneered modular designs that allow seamless integration into existing production lines—a boon for businesses aiming to scale without operational downtime.

What sets Chinese manufacturers apart is their ability to marry cost-efficiency with uncompromising quality. By leveraging economies of scale and state-sponsored R&D initiatives, facilities like the China yuanlin factory deliver robust machinery that adheres to international safety protocols. Their vacuum tumblers and multi-axis slicers, crafted from food-grade alloys, exemplify durability while meeting stringent EU and USDA regulations.

Sustainability is another cornerstone of Meat Equipment China. Progressive factories are adopting closed-loop water systems and energy recovery technologies, reducing the carbon footprint of meat processing. The China yuanlin factory has emerged as a trailblazer in this realm, deploying solar-powered curing chambers and biodegradable lubricants—innovations that resonate with eco-conscious global buyers.

For businesses seeking tailored solutions, Chinese suppliers offer unparalleled flexibility. Whether customizing portion sizes for niche markets or retrofitting legacy systems with IoT sensors, Meat Equipment China adapts to diverse needs. The China yuanlin factory’s collaborative approach—engaging clients from design to deployment—ensures equipment aligns perfectly with operational goals.

In an era where supply chain resilience is critical, partnering with Meat Equipment China provides a strategic edge. Competitive pricing, rapid prototyping, and agile logistics networks position Chinese manufacturers as indispensable allies for meat processors worldwide. As the China yuanlin factory continues to innovate, it underscores China’s ascendancy in shaping the future of food technology.

Investing in Chinese meat processing machinery isn’t just a procurement decision—it’s a commitment to progress. By embracing the ingenuity of Meat Equipment China, businesses can elevate productivity, sustainability, and profitability in an increasingly competitive market.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Stuffed Meatball Machine

Stuffed Meatball Machine Multifunctional Noodle Making Machine

Multifunctional Noodle Making Machine Multifunction Pasta Machine

Multifunction Pasta Machine Cooking Drying Oven

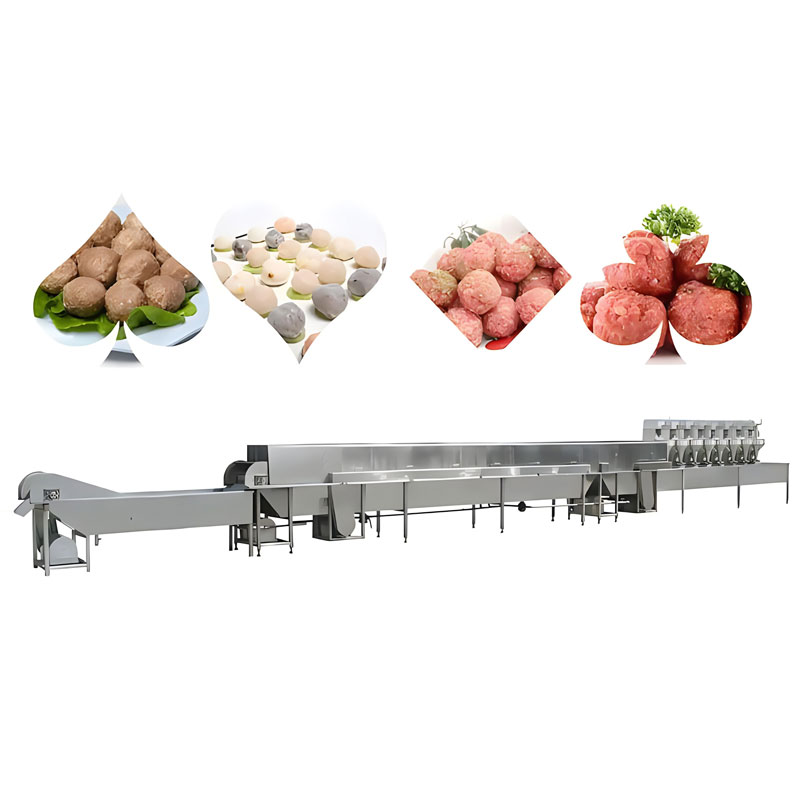

Cooking Drying Oven Meatball Production Line

Meatball Production Line Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine Patty Maker Machine

Patty Maker Machine