Meat Blender Machine - Chinese Manufacturer, Factory, Supplier

In the modern food processing industry, the Meat Blender Machine has emerged as an essential tool in meat production lines. This advanced equipment utilizes cutting-edge blending technology and smart control systems to ensure the even distribution of various meat ingredients, preserving the natural texture and nutritional value of the products. Its high efficiency and precision have made the Meat Blender Machine a preferred choice among both large-scale meat processing plants and smaller food manufacturing enterprises.

The Meat Blender Machine is designed for stability and energy efficiency, making it capable of continuous operation while maintaining optimal performance. With its integrated automation system, operators can monitor the blending process in real-time and adjust parameters as needed to ensure that every batch meets strict quality standards. This intelligent control not only enhances product consistency but also minimizes human error during production, thus improving overall operational safety.

One of the significant advantages of the Meat Blender Machine is its construction using high-quality stainless steel, which complies with international standards for food safety and hygiene. The easy-to-clean design reduces the risk of cross-contamination, ensuring that the final meat products remain pure and safe for consumption. Additionally, the machine’s low noise output and minimal maintenance requirements contribute to a more environmentally friendly and cost-effective production process.

As consumer demand for high-quality, safe, and sustainably produced meat continues to grow, the role of the Meat Blender Machine becomes even more critical. Its ability to streamline production and reduce processing costs while delivering consistent product quality makes it a cornerstone of modern meat processing facilities. Moreover, the ongoing technological advancements in automation and smart controls promise further enhancements in performance and operational efficiency.

Looking ahead, the Meat Blender Machine is expected to play an increasingly important role in the evolution of the food processing industry. As manufacturers adopt more sophisticated technologies, this machine will not only drive improvements in production speed and product quality but also support the industry’s move towards greener, more sustainable practices. In summary, the Meat Blender Machine stands out as a reliable, innovative solution that addresses both current industry challenges and future market demands.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Portable Flake Ice Machine

Portable Flake Ice Machine Bowl Cutter

Bowl Cutter Cooking Drying Oven

Cooking Drying Oven Chicken Feet Cutting Machine

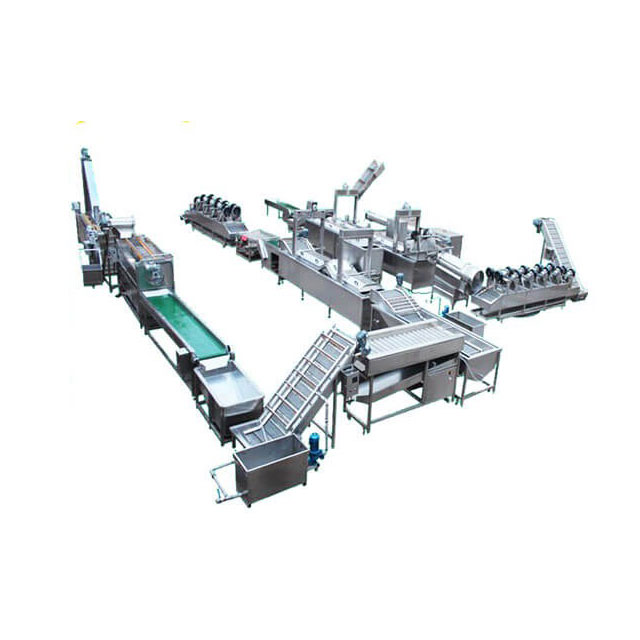

Chicken Feet Cutting Machine Frozen French Fries Production Line

Frozen French Fries Production Line Gas Shawarma Machine

Gas Shawarma Machine YL-W-06 Commercial Water Purification Equipment

YL-W-06 Commercial Water Purification Equipment