Italian Tomato Sauce Making Machine - Chinese Manufacturer, Factory, Supplier

Introduction: The Importance of Efficient Tomato Sauce Production

The tomato sauce industry is a global powerhouse, with an ever-growing demand for high-quality, flavorful products. As the heart of many beloved dishes—pasta, pizza, stews, and more—tomato sauce plays a pivotal role in global cuisine. However, the production of this kitchen staple isn’t as simple as it may seem. Behind every jar or can of rich, velvety tomato sauce is a highly complex, efficient production process that hinges on the right equipment. Efficiency is the key to creating a consistent product, maintaining cost-effectiveness, and scaling operations.

The cornerstone of achieving top-tier tomato sauce production lies in selecting the right machine. Whether you're a small-scale producer or a large manufacturing plant, the right equipment ensures that every batch is made with the utmost precision and flavor. This article will dive into the world of Italian tomato sauce making machines, exploring their features, benefits, and the impact they have on both quality and business operations.

Why Quality Tomato Sauce Starts with the Right Equipment

Producing high-quality tomato sauce is more than just sourcing ripe tomatoes. It’s about harnessing the power of cutting-edge equipment that transforms raw ingredients into a consistently smooth, flavorful product. The right equipment ensures that each step of the production process—from washing and peeling tomatoes to packaging the final product—is completed with precision and care.

Top-tier tomato sauce making machines can reduce human error, speed up production, and, most importantly, preserve the natural flavors and nutrients of the tomatoes. When paired with the right techniques, these machines are the key to maintaining consistency, taste, and efficiency, all while minimizing waste and production time.

Overview of the Italian Tomato Sauce Making Machine

Italian tomato sauce making machines are the gold standard in the food processing industry. Crafted with a rich tradition of innovation, these machines integrate advanced technology and timeless Italian craftsmanship. Known for their precision and durability, Italian machines offer unique features that set them apart from other models. Whether you’re making classic marinara, rich pomodoro, or a gourmet specialty sauce, these machines ensure that every batch meets the highest standards of quality and consistency.

Italian manufacturers are renowned for their attention to detail, building machines that are both versatile and reliable. From small artisanal producers to large-scale manufacturers, Italian machines cater to all types of production needs, making them the preferred choice for businesses worldwide.

Understanding the Basics of Italian Tomato Sauce Production

Tomato sauce production involves several critical stages, each of which requires precise handling to ensure the desired outcome. It all begins with the tomatoes themselves—picked at peak ripeness and often processed within hours of harvest to preserve their natural flavor and nutrition. Once the tomatoes arrive at the production facility, they are washed, peeled, and often crushed or pureed, depending on the final texture required.

From here, the sauce is cooked, often with a blend of spices, herbs, and other ingredients. The final steps involve pasteurization, cooling, and packaging. Throughout the entire process, the use of specialized equipment like blenders, pureeing machines, and pasteurizers ensures that the sauce remains fresh, consistent, and safe for long-term storage.

The Traditional Methods vs. Modern Machinery

For centuries, traditional methods of making tomato sauce were practiced—usually involving slow cooking and manual labor. However, with the advent of modern machinery, production has become much more efficient, hygienic, and scalable. Today, machines automate most of the work, reducing the risk of contamination and ensuring that the sauce is prepared with consistent flavor and texture.

While traditional methods still hold charm for some artisanal producers, modern machinery offers unparalleled benefits. Automation allows for faster production, higher consistency, and the ability to scale without sacrificing quality. Additionally, modern machines can precisely control cooking times and temperatures, something that’s nearly impossible with manual methods.

The Role of Italian Tomato Sauce in Global Cuisine

Italian tomato sauce is more than just a product; it's a cultural phenomenon. From Italy’s humble kitchens to restaurants and homes around the world, the rich, savory taste of Italian-style tomato sauce has become a cornerstone of global cuisine. It is the base for countless dishes, from spaghetti and pizza to meats and vegetables, offering versatility and comfort in every bite.

The growing global demand for Italian tomato sauce has led to an increased focus on efficient production methods. As more regions embrace the flavors of Italy, the need for high-quality, scalable production solutions has never been greater.

Key Features of an Italian Tomato Sauce Making Machine

Precision and Consistency: Ensuring Perfect Tomato Sauce Every Time

Consistency is key in tomato sauce production. Consumers expect the same flavor, texture, and color in every jar or can they purchase. Italian tomato sauce making machines excel in delivering uniform results, from blending to cooking. Thanks to precise temperature and speed controls, these machines guarantee that each batch is identical, meeting the high standards of both producers and consumers.

Speed and Efficiency: Meeting High-Demand Production

With high global demand, speed is essential for producers. Italian machines are designed to operate at high speeds, processing large quantities of tomatoes and turning them into sauce in record time. The speed does not come at the cost of quality—these machines manage the balance between efficiency and maintaining the perfect flavor.

Versatility: Customizing Sauce Textures and Flavors

One of the standout features of Italian tomato sauce making machines is their versatility. From smooth sauces to chunky versions, these machines allow producers to create a wide range of textures and flavors. Customizable settings for grinding, blending, and pureeing provide the flexibility needed to meet different market demands or personal preferences.

Durability and Reliability: The Backbone of Long-Term Operation

Italian machinery is built to last. With heavy-duty construction and high-quality materials, these machines withstand the rigors of continuous operation. Businesses can rely on them for years of trouble-free service, making them a long-term investment for anyone looking to build or scale a tomato sauce production line.

How Italian Tomato Sauce Making Machines Improve Production Efficiency

Reducing Labor Costs with Automation

Automation is a game-changer in food production, especially in large-scale operations. Italian tomato sauce making machines automate many of the manual tasks, such as peeling, grinding, and cooking. This reduces the need for a large labor force, cutting down on labor costs while boosting overall efficiency. Operators are only needed to supervise the process, ensuring that production is smooth and continuous.

Minimizing Wastage for Cost-Effective Production

Modern Italian tomato sauce making machines are designed with precision to minimize waste. Every drop of tomato is used efficiently, reducing raw material costs and maximizing profits. These machines are engineered to optimize the processing of tomatoes, ensuring that each batch yields the highest quality sauce possible with minimal loss.

Increasing Output without Compromising Quality

Scaling up production while maintaining quality can be challenging. Italian machines are built with this in mind, offering high output capacity without sacrificing the integrity of the sauce. With optimized workflows and automated processes, producers can meet increasing demand without ever compromising on flavor or texture.

Types of Italian Tomato Sauce Making Machines

Blenders and Mixers for the Perfect Consistency

Blenders and mixers are essential for creating the perfect texture in tomato sauce. Whether you prefer a smooth, silky consistency or a chunkier texture, these machines can be adjusted to meet specific needs. They ensure that all ingredients are evenly distributed, creating a uniform flavor and mouthfeel in every batch.

Puree Machines: Getting Smooth, Silky Sauces

For a smooth, high-quality puree, specialized puree machines are used. These machines separate the seeds and skins from the tomatoes, leaving only the pure pulp behind. The result is a silky, smooth texture that’s perfect for high-end sauces.

Pasteurizers: Ensuring Safe, Long-Lasting Sauces

Pasteurization is a critical step in ensuring that tomato sauce is safe for consumption and has a long shelf life. Italian pasteurizers use controlled heat to kill any bacteria or microorganisms without compromising the sauce’s flavor and texture. This step is essential for commercial production, as it allows the sauce to be stored for extended periods.

Filling and Packaging Machines: For Quick and Efficient Distribution

Once the tomato sauce is made, it must be quickly and efficiently packaged. Italian filling and packaging machines ensure that each jar or can is filled to the right level, sealed securely, and ready for distribution. These machines streamline the final steps of production, reducing labor costs and preventing contamination.

Why Choose an Italian Tomato Sauce Making Machine Over Other Models?

The Italian Tradition of Craftsmanship and Quality

Italy has a long history of producing some of the world’s finest food equipment, and tomato sauce making machines are no exception. Built with a focus on durability, precision, and performance, Italian machines offer exceptional quality. They combine traditional craftsmanship with modern technology to deliver products that stand out in both performance and longevity.

How Italian Machines Lead the Industry in Performance and Innovation

Italian manufacturers have long been leaders in food processing technology. Their machines are at the forefront of innovation, featuring the latest in automation, smart technology, and energy efficiency. By continually improving upon their designs, Italian manufacturers ensure that their tomato sauce making machines lead the industry in performance and cutting-edge capabilities.

Key Factors to Consider When Choosing the Right Tomato Sauce Making Machine

Machine Size and Capacity: Meeting Your Production Needs

Choosing the right machine size depends on the scale of your operations. Small-scale producers may opt for compact models, while larger manufacturers may require machines with higher capacity and automation. It's essential to match machine size with production goals to optimize efficiency and prevent over- or underproduction.

Power Consumption and Energy Efficiency

Energy efficiency is a significant consideration for modern tomato sauce making machines. Machines that consume less energy reduce operating costs and lower the environmental footprint of production. Italian machines often come equipped with energy-saving features that ensure optimal performance without wasting energy.

Ease of Cleaning and Maintenance

Hygiene is paramount in food production. Machines that are easy to clean and maintain will save time and reduce the risk of contamination. Italian tomato sauce making machines are designed with user-friendly features that make maintenance and cleaning straightforward, ensuring that operators can focus on the quality of the product.

Price vs. Value: Balancing Budget and Quality

While Italian machines may come with a higher upfront cost, their reliability, efficiency, and longevity make them a valuable investment. Businesses must weigh the initial price against the long-term savings and benefits. Over time, the increased efficiency and reduced labor costs will offset the higher purchase price, making Italian machines a sound investment.

Technological Innovations in Modern Tomato Sauce Making Machines

Smart Technology: Monitoring and Control Systems

Modern Italian machines often come with advanced monitoring systems that allow operators to track performance in real-time. These systems provide feedback on everything from temperature to blending speed, ensuring optimal conditions throughout production.

Advanced Heat Treatment and Sterilization Features

Heat treatment and sterilization are essential for producing safe, long-lasting tomato sauce. Italian machines are equipped with advanced heat management systems that precisely control temperature and pressure to maintain product safety without compromising flavor.

The Role of Automation in Streamlining Operations

Automation is a cornerstone of modern tomato sauce production. Italian machines feature automated processes that reduce manual labor and improve consistency. Automation streamlines operations, allowing businesses to focus on quality and innovation while increasing production efficiency.

How to Maintain Your Italian Tomato Sauce Making Machine

Routine Maintenance for Long-Term Durability

Maintaining your tomato sauce making machine is essential for ensuring its longevity and optimal performance. Routine checks, such as lubricating moving parts and inspecting seals, will help prevent breakdowns and ensure that the machine continues to operate smoothly.

Troubleshooting Common Issues with Tomato Sauce Machines

From clogged pipes to inconsistent mixing, troubleshooting minor issues is part of regular machine upkeep. Many Italian machines come with detailed guides to help operators address common problems quickly, minimizing downtime and maintaining production efficiency.

The Importance of Using High-Quality Ingredients for Optimal Performance

The quality of the ingredients used in production directly affects the performance of the machine. High-quality tomatoes, spices, and other ingredients ensure that the machine operates at its best, resulting in a superior sauce that meets both flavor and texture expectations.

The Environmental Benefits of Using Efficient Tomato Sauce Making Machines

Reducing Waste and Enhancing Sustainability

Modern Italian tomato sauce making machines are designed to minimize waste by efficiently processing ingredients. This not only helps reduce costs but also contributes to sustainability, ensuring that raw materials are used as efficiently as possible.

Energy-Efficient Features for Eco-Friendly Production

Energy-efficient features reduce the carbon footprint of production processes. Italian tomato sauce making machines are designed to operate with minimal energy consumption, lowering operational costs and benefiting the environment.

How Modern Machines Contribute to Reducing Carbon Footprints

By optimizing processes like heating, mixing, and packaging, modern machines reduce energy consumption and greenhouse gas emissions. This makes Italian machines a more environmentally conscious choice for businesses looking to enhance their sustainability efforts.

Cost Considerations and Return on Investment

Upfront Costs vs. Long-Term Savings

While the initial investment in Italian tomato sauce making machines may be higher than other options, the long-term benefits often outweigh the upfront costs. With increased efficiency, reduced labor expenses, and lower waste, businesses see a significant return on investment over time.

How to Calculate the ROI of a Tomato Sauce Making Machine

To calculate ROI, businesses should consider factors like reduced labor costs, improved production speeds, and lower waste rates. Comparing the savings generated by the new machine against its initial cost provides a clear picture of long-term profitability.

Financing and Leasing Options for Businesses

For businesses concerned about upfront costs, financing and leasing options are available. These flexible payment plans allow companies to acquire the machinery they need without straining their budget, with payments spread over time.

The Impact of Italian Tomato Sauce Machines on Small and Large Scale Operations

How Smaller Businesses Benefit from Advanced Machinery

Even smaller producers can benefit from Italian tomato sauce making machines. These machines are scalable, allowing businesses to start with a smaller model and upgrade as their needs grow. They also offer high efficiency, ensuring that even smaller operations can keep up with demand.

Scaling Production for Larger Companies with State-of-the-Art Equipment

For large-scale operations, Italian machines offer high output capacity and automation, ensuring that companies can meet the demands of larger markets without sacrificing quality. These machines make scaling production seamless and cost-effective, allowing companies to expand their reach without additional overhead.

Customer Testimonials: Real Stories of Success

Case Studies from Businesses Using Italian Tomato Sauce Machines

Real-world examples demonstrate the benefits of Italian tomato sauce making machines. From small family-owned businesses to large multinational manufacturers, customers have reported increased efficiency, higher-quality products, and reduced labor costs.

The Benefits Experienced by Users Worldwide

Across the globe, businesses are experiencing the advantages of Italian tomato sauce machines. From improved production timelines to higher product consistency, users are reaping the rewards of investing in state-of-the-art equipment.

The Future of Tomato Sauce Production: Trends to Watch

Advances in Automation and Robotics

As technology continues to evolve, automation and robotics will play an increasingly significant role in tomato sauce production. These innovations promise to further streamline operations, improve consistency, and reduce labor costs.

The Shift Towards Healthier and Organic Tomato Sauce Production

Consumer demand for healthier, organic products is growing. Tomato sauce manufacturers are responding by creating healthier recipes and incorporating sustainable practices. Modern machines can accommodate these shifts by allowing for easy ingredient customization and enhanced processing methods.

Innovative Packaging Solutions in the Tomato Sauce Industry

Packaging plays a vital role in preserving freshness and extending shelf life. Italian manufacturers are at the forefront of developing innovative packaging solutions that ensure tomato sauces stay fresh while also appealing to environmentally conscious consumers.

Frequently Asked Questions (FAQs) About Italian Tomato Sauce Making Machine

What Makes Italian Tomato Sauce Making Machines Different from Other Machines?

Italian tomato sauce making machines stand out due to their exceptional craftsmanship, precision, and reliability. They are built with advanced technology that ensures high-quality production, offering consistent results batch after batch. Italian machines also excel in versatility, allowing for customization in texture, flavor, and production speed, making them ideal for both small-scale artisanal producers and large commercial operations. Their durability and efficiency, combined with the use of energy-saving features, make them a top choice worldwide.

How Long Do Italian Tomato Sauce Making Machines Typically Last?

Italian tomato sauce making machines are renowned for their durability. With proper maintenance and care, these machines can last for many years, with many models designed to function reliably for over a decade. Regular maintenance, such as routine cleaning and checks on mechanical components, will help extend their lifespan and ensure they continue to perform at optimal levels throughout their service life.

How Do I Choose the Right Size Tomato Sauce Making Machine for My Business?

Choosing the right size machine depends on your production goals and the scale of your operation. Smaller businesses or artisanal producers may opt for more compact, lower-capacity machines that offer flexibility and ease of use. Larger businesses or manufacturers with high-demand production needs should consider machines with higher capacity and more automation features to increase output while maintaining consistency. It’s important to assess your current and future production needs, budget, and available space to make the best choice.

What Type of Maintenance Do Italian Tomato Sauce Making Machines Require?

Italian tomato sauce making machines are relatively low-maintenance, but routine care is essential for ensuring their long-term reliability. Regular cleaning of machine parts, including blenders, pureeing components, and pasteurizers, is vital to prevent contamination and preserve product quality. It’s also crucial to lubricate moving parts, check for any wear and tear, and replace parts like seals or filters as needed. Many Italian machines come with user manuals or automated systems to assist with maintenance tasks, making upkeep more manageable for operators.

Can I Customize My Tomato Sauce Using These Machines?

Yes, one of the key advantages of Italian tomato sauce making machines is their versatility. Many models allow you to adjust settings such as blending speed, grinding intensity, and heat treatment to customize the texture, thickness, and flavor of your sauce. Whether you want a smooth, silky puree or a chunkier, more rustic sauce, these machines can accommodate a wide range of preferences and requirements, allowing you to create unique, high-quality products.

Are Italian Tomato Sauce Making Machines Energy Efficient?

Yes, Italian tomato sauce making machines are designed with energy efficiency in mind. Many models feature advanced technology that reduces power consumption while maintaining high levels of performance. By optimizing heating, mixing, and other processes, these machines minimize energy waste, resulting in lower operating costs and a reduced environmental impact. For businesses looking to cut energy costs while maintaining high production levels, energy-efficient Italian machines are an ideal choice.

What Are the Key Benefits of Automation in Tomato Sauce Production?

Automation in tomato sauce production significantly enhances efficiency and consistency. By automating tasks such as blending, pureeing, cooking, and packaging, businesses can reduce labor costs, minimize human error, and increase production speed. Automated systems ensure that each batch is processed under the same conditions, guaranteeing consistent flavor, texture, and quality. Additionally, automation helps businesses scale operations quickly without sacrificing quality, making it easier to meet growing demand.

Can I Scale My Production with Italian Tomato Sauce Making Machines?

Absolutely. Italian tomato sauce making machines are designed to cater to both small and large-scale production needs. Whether you’re just starting or planning to scale up, these machines offer flexibility and customization options. For small businesses, there are compact models that allow for incremental growth, while larger operations can invest in high-capacity machines that automate much of the production process, enabling them to meet higher demands without compromising quality.

What Are the Common Problems with Tomato Sauce Making Machines and How Can They Be Prevented?

Common issues with tomato sauce making machines include clogging, inconsistent texture, and mechanical failures. These problems can often be prevented by ensuring regular maintenance and cleaning. Clogging can be avoided by regularly cleaning pipes and filters to remove any buildup of tomato skin or seeds. Inconsistent texture can be addressed by adjusting machine settings or troubleshooting motor and blade functions. Regular inspections and following the manufacturer’s guidelines will help catch potential issues early and keep production running smoothly.

What Are the Costs Involved in Purchasing an Italian Tomato Sauce Making Machine?

The cost of an Italian tomato sauce making machine varies based on its size, features, and production capacity. While these machines typically come with a higher upfront cost compared to other models, the long-term savings in labor, energy, and waste reduction make them a valuable investment. When calculating the total cost, it's essential to consider not only the purchase price but also the operational savings, efficiency gains, and return on investment (ROI) over time. Financing and leasing options are often available to help manage initial costs for businesses.

Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Sauce Filling Machine

Sauce Filling Machine Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Tomato Paste Production Line

Tomato Paste Production Line Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Vegetable Processing Line

Vegetable Processing Line Cake Production Line

Cake Production Line Chocolate Production Line

Chocolate Production Line AP Series Flake Ice Machine

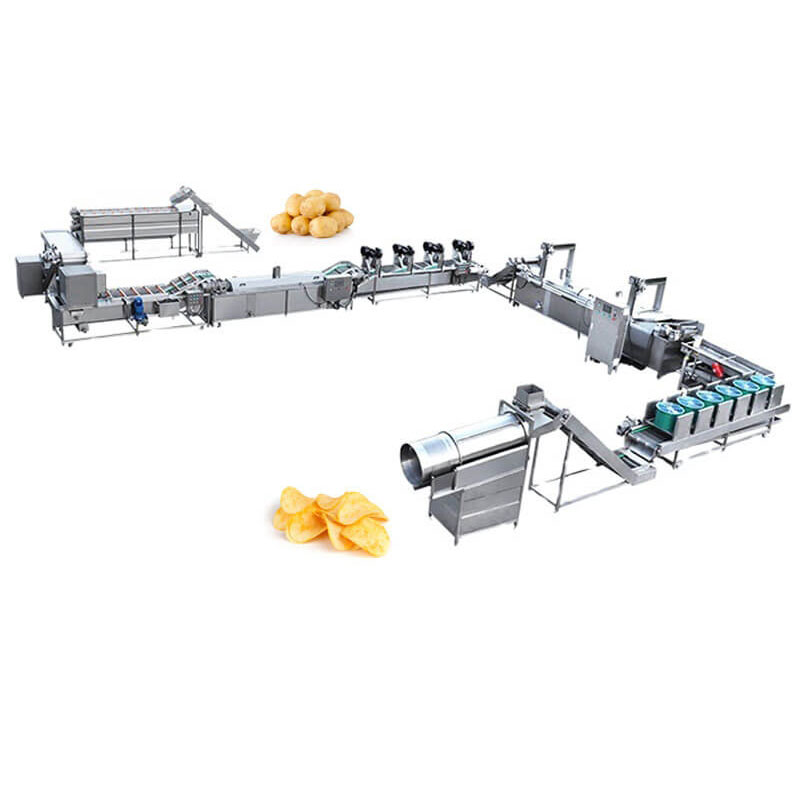

AP Series Flake Ice Machine Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Full-View Electric Oven

Full-View Electric Oven Cheese Production Line

Cheese Production Line