Industrial Meat Mixer Machine - Chinese Manufacturer, Factory, Supplier

Industrial meat mixer machines are advanced processing systems designed to handle high-volume, consistent production of meat-based products in commercial and industrial settings. These machines are engineered to efficiently blend, grind, and portion large quantities of meat, spices, and additives, ensuring uniform texture and flavor while meeting strict food safety and operational standards. They are critical for meat processors, slaughterhouses, food manufacturers, and large-scale businesses aiming to streamline workflows and scale production without compromising quality.

Key Features and Functional Benefits

Industrial meat mixer machines prioritize high capacity and durability, with motor power ranging from 5 to 20 HP or more, enabling processing speeds of 50–500 kg/hour depending on the model. Key features include:

Heavy-duty stainless steel construction : Resistant to corrosion and easy to clean, ensuring compliance with FDA and HACCP standards.

Adjustable grinding systems : Multiple plate and blade configurations allow customization of meat texture (e.g., coarse for sausages, fine for patties).

Integrated mixing chambers : Equipped with rotating paddles or augers for thorough blending of ingredients, even with high-fat or tough meat cuts.

Automated controls : Some models feature PLC-based systems or touchscreen interfaces for precision temperature and speed adjustments.

Safety features : Emergency stop buttons, interlock guards, and noise-reduction designs align with OSHA and CE safety certifications.

Design for Efficiency and Scalability

Industrial machines often incorporate modular designs to adapt to diverse production needs. For example, some systems integrate conveyor belts for continuous feeding, reducing manual labor. Others offer separate grinding and mixing chambers for multistage processing. The hygienic design with nooks and crevices minimized simplifies CIP (Clean-in-Place) protocols, minimizing downtime between batches.

Applications Across Industries

Meat Processing Plants : Bulk production of sausages, jerky, or ready-to-eat meals.

Industrial Kitchens : Large-scale preparation of patties, meatballs, or institutional catering products.

Specialty Markets : Customization for halal, organic, or plant-based meat alternatives requiring precise texture control.

Automated Production Lines : Integration with packaging systems for end-to-end processing.

Maintenance and Long-Term Reliability

To ensure longevity, operators must follow rigorous preventive maintenance protocols , such as:

Regular blade sharpening and replacement of worn parts.

Thermal management to prevent motor overheating.

Compliance with hygiene standards to avoid bacterial growth.

Investing in durable components (e.g., hardened steel blades, reinforced bearings) reduces repair costs and downtime.

Selecting the Right Machine

Key considerations for buyers include:

Capacity : Align with daily production targets (e.g., 50 kg/hour for small plants vs. 500 kg/hour for large-scale facilities).

Customization : Adjustable settings for texture, temperature, and automation levels.

Certifications : Ensure compliance with ISO , HACCP , and regional safety regulations.

Support : Choose manufacturers offering training, spare parts, and technical assistance.

Conclusion

Industrial meat mixer machines are pivotal for businesses aiming to achieve scalability , consistency , and food safety in high-volume meat production. Their robust engineering, advanced controls, and adaptability make them essential for modern food manufacturing. By prioritizing durability, automation, and compliance, these machines empower enterprises to meet growing consumer demand while maintaining operational efficiency and cost-effectiveness.

Automatic Meat Mixer Machine

Automatic Meat Mixer Machine Vacuum Stuffing Machine

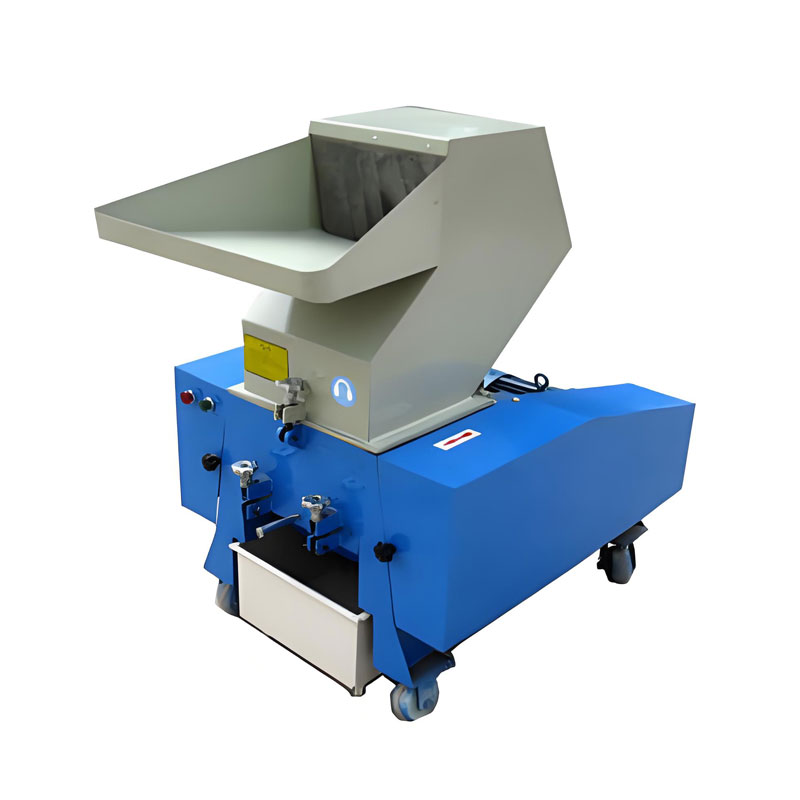

Vacuum Stuffing Machine Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Industrial Frozen Meat Slicing Machine

Industrial Frozen Meat Slicing Machine Vacuum Meat Tumbler

Vacuum Meat Tumbler Salmon Processing Line

Salmon Processing Line Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine Multifunction Pasta Machine

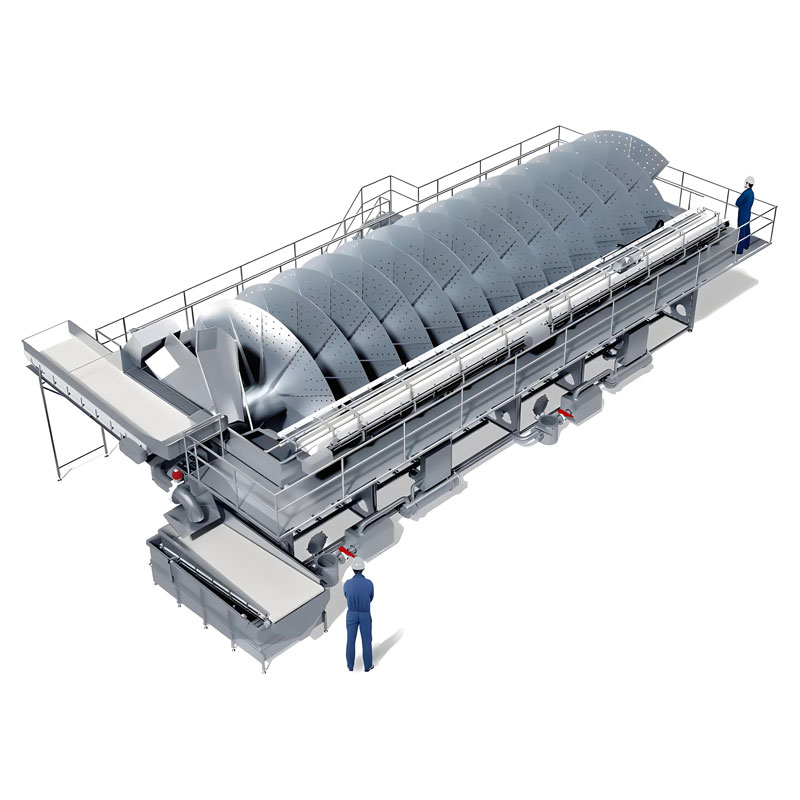

Multifunction Pasta Machine Poultry Slaughtering Line

Poultry Slaughtering Line