Frozen Meat Vending Machine - Chinese Manufacturer, Factory, Supplier

The Frozen Meat Vending Machine emerges as a disruptive innovation in food retail, redefining accessibility to perishables through seamless integration of cryogenic preservation and automated dispensing. Designed for markets demanding year-round availability of premium meat products, these machines leverage cutting-edge thermal regulation systems to maintain sub-zero temperatures without compromising product integrity.

China , a global leader in refrigeration technology and urban convenience solutions, has pioneered advancements in this sector. Domestic manufacturers in China have engineered machines with multi-layered thermal isolation , ensuring that beef, poultry, or seafood remains at -18°C to -25°C—critical thresholds for preventing microbial growth and preserving nutritional value. The Frozen Meat Vending Machine ’s cryogenic preservation modules and rapid cooldown mechanisms minimize temperature fluctuations during restocking, a breakthrough for perishable goods.

Beyond technical prowess, these machines address logistical challenges in China’s food retail sector . With urban populations seeking 24/7 access to fresh-frozen proteins, the devices enable decentralized distribution. Their touchscreen interfaces and QR code payment systems cater to tech-savvy consumers, while smart inventory management alerts operators to restock via IoT connectivity.

The environmental impact is equally transformative. By reducing reliance on traditional cold-chain logistics, China -based models cut carbon emissions through localized storage. Their energy-efficient compressors and low-wattage operation align with the nation’s sustainability goals, offering a eco-conscious alternative to conventional supermarkets.

For businesses, the Frozen Meat Vending Machine slashes operational costs by eliminating staffing needs and reducing food waste. The tamper-proof hermetic seals and sanitation protocols ensure compliance with stringent food safety regulations, a priority in China ’s regulatory landscape.

Innovations like China -developed modular refrigeration units allow customization for niche markets—from halal-certified meats to organic offerings. The machines’ anti-fogging glass panels and LED-lit displays enhance customer appeal, showcasing products attractively while maintaining sub-zero conditions.

As urbanization accelerates, the Frozen Meat Vending Machine bridges gaps in last-mile food delivery. Its self-cleaning cycles and remote diagnostics reduce downtime, ensuring reliability in high-traffic areas like metro stations or residential complexes.

This technology embodies the future of food retail, merging convenience, sustainability, and precision. For China ’s growing middle class and global export markets, it’s a paradigm shift in how frozen proteins are accessed and consumed.

Investing in a Frozen Meat Vending Machine isn’t just adopting machinery—it’s embracing a smarter, more efficient ecosystem for food distribution.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Brush Potato Washing Peeling Machine

Brush Potato Washing Peeling Machine Churros Making Machine

Churros Making Machine Fish Speed Cleaning Machine

Fish Speed Cleaning Machine Chicken Feet Cutting Machine

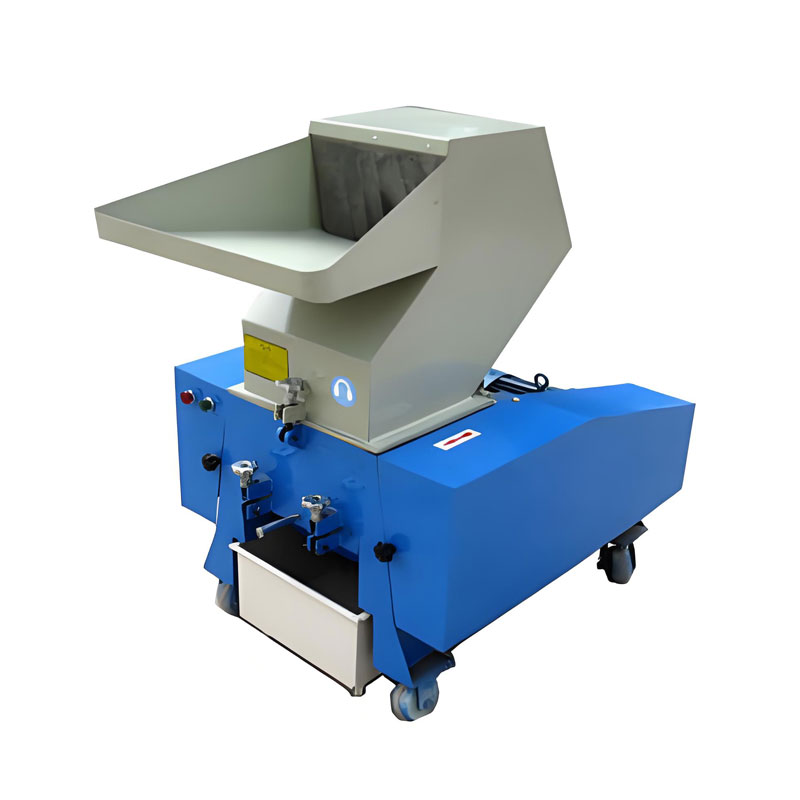

Chicken Feet Cutting Machine Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Frozen Meat Slicer

Frozen Meat Slicer