Frozen Meat Bone Saw Machine - Chinese Manufacturer, Factory, Supplier

The Frozen Meat Bone Saw Machine stands as a cornerstone of modern meat processing, engineered to tackle the unique challenges of cutting through frozen meat and bone with unmatched precision and efficiency. Designed for industrial-scale operations, this machinery combines cutting-edge technology with rugged durability, ensuring seamless integration into high-volume production lines. From poultry to seafood, its applications span diverse sectors, delivering consistent results even under the harshest conditions.

At the heart of this innovation lies advanced hydraulics and industrial-grade construction. The machine’s China Yuanlin Factory -manufactured components are forged to withstand repeated stress, guaranteeing longevity. Equipped with diamond-tipped blades and automated feed systems, it effortlessly slices through frozen carcasses, minimizing waste and maximizing yield. Unlike conventional methods, this saw operates at variable speeds, adapting to material density without compromising blade integrity.

Safety and ease of use are paramount. The Frozen Meat Bone Saw Machine features a user-friendly control panel with intuitive settings, allowing operators to adjust parameters like cutting depth and speed. Its ergonomic design reduces physical strain, while integrated safety guards prevent accidental exposure to moving parts. The enclosed workspace also minimizes noise pollution, creating a safer, more productive environment for workers.

The China Yuanlin Factory distinguishes itself through its commitment to quality and innovation. As a leading global supplier, the factory leverages decades of expertise to refine every aspect of production. Each machine undergoes rigorous testing to ensure compliance with international safety standards, reflecting a dedication to excellence. This attention to detail translates into reliable performance, even when handling the toughest frozen materials.

One of the standout advantages of this technology is its adaptability. The Frozen Meat Bone Saw Machine can be customized to suit specific operational needs, whether for small-scale processors or large industrial facilities. Its compact footprint and modular design allow seamless installation alongside existing equipment, reducing downtime during setup.

Environmental sustainability is another key benefit. By reducing energy consumption through optimized blade efficiency and minimizing material waste, the machine aligns with eco-conscious practices. This not only lowers operational costs but also positions businesses as environmentally responsible leaders in their industries.

Investing in a Frozen Meat Bone Saw Machine from the China Yuanlin Factory is an investment in precision, productivity, and future-proofing your operation. With its robust build, intelligent features, and proven reliability, this machinery sets a new benchmark for efficiency in meat processing. As industries demand higher standards of quality and safety, this tool emerges as an indispensable asset, empowering businesses to meet—and exceed—those expectations.

In an era where efficiency and accuracy are non-negotiable, the Frozen Meat Bone Saw Machine and the China Yuanlin Factory ’s expertise offer a pathway to transformative results. Whether you’re optimizing a poultry plant or scaling seafood production, this technology ensures that every cut is precise, every process is streamlined, and every outcome is exceptional.

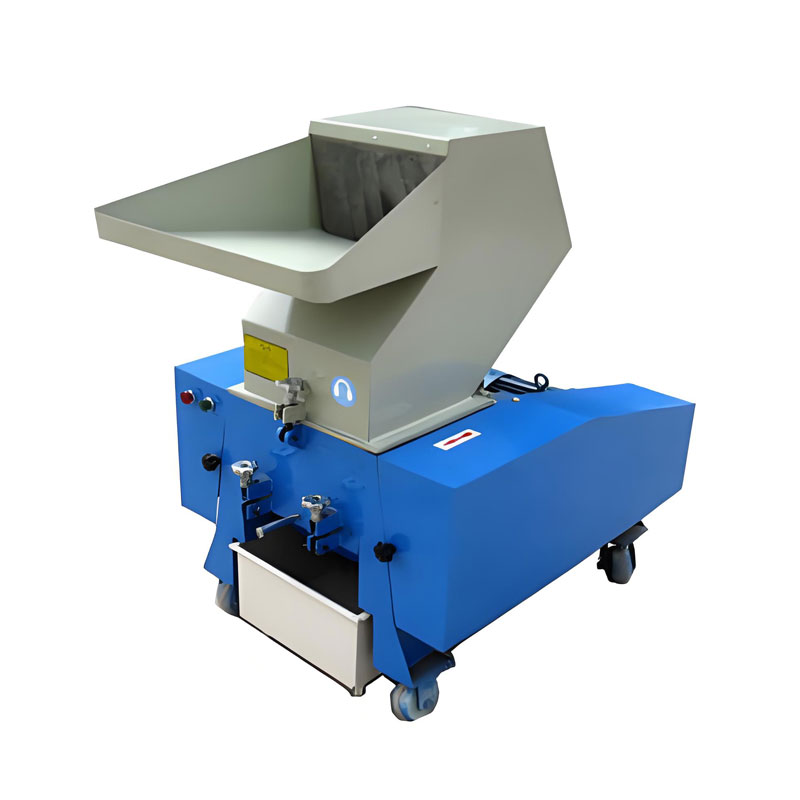

Automatic Bone Crushing Machine

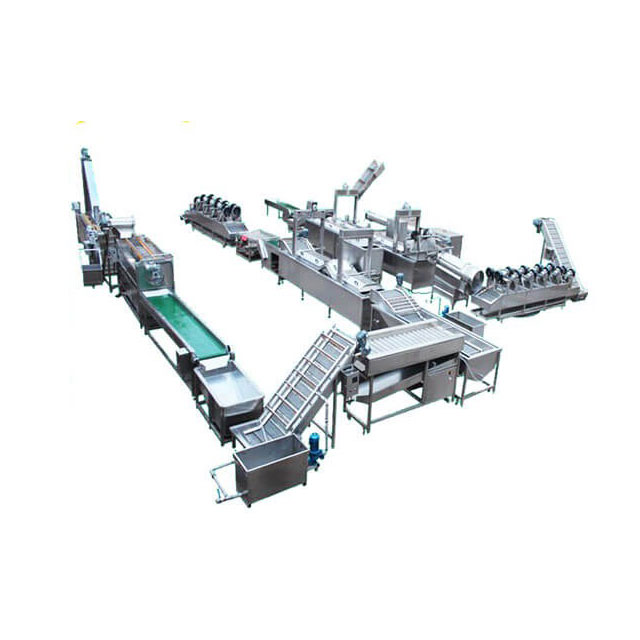

Automatic Bone Crushing Machine Frozen French Fries Production Line

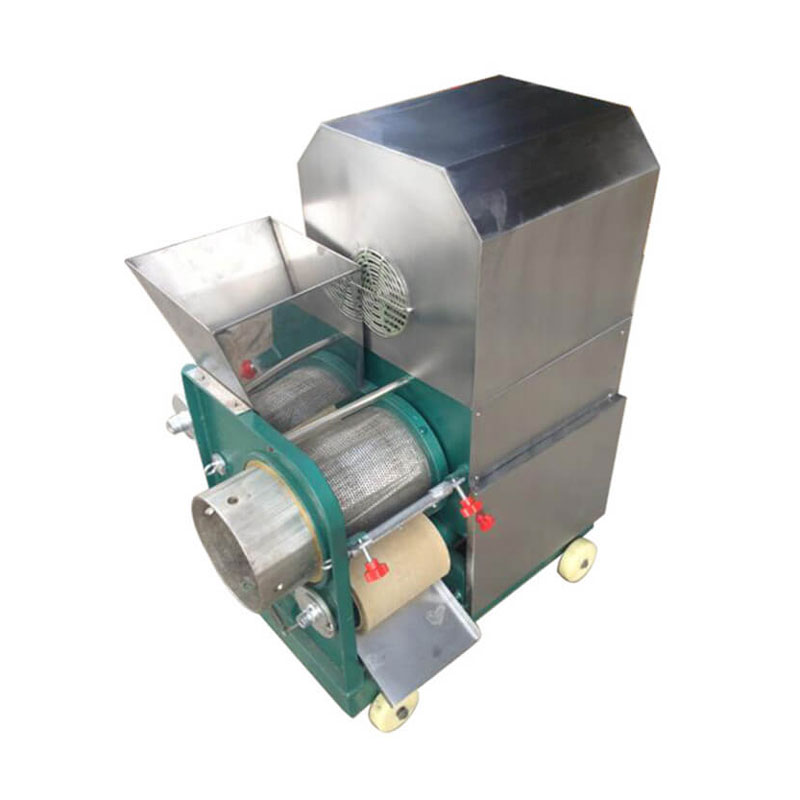

Frozen French Fries Production Line Fish Deboner Machine

Fish Deboner Machine Bone Crusher Machine

Bone Crusher Machine Frozen Meat Ribs Dicing Machine

Frozen Meat Ribs Dicing Machine Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine Frozen Meat Cube Cutting Machine

Frozen Meat Cube Cutting Machine Industrial Frozen Meat Slicing Machine

Industrial Frozen Meat Slicing Machine Frozen Meat Grinder

Frozen Meat Grinder Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Chicken Cutting Machine

Automatic Chicken Cutting Machine YL-W-04 Commercial Water Purification Equipment

YL-W-04 Commercial Water Purification Equipment Membrane Skinner

Membrane Skinner Cooking Drying Oven

Cooking Drying Oven Microwave Pigskin Puffing Machine

Microwave Pigskin Puffing Machine Tofu Production Line

Tofu Production Line Twist Potato Machine

Twist Potato Machine