Fish Cutting Machine Price - Chinese Manufacturer, Factory, Supplier

Fish cutting machines are essential for aquatic processing efficiency, with prices varying based on functionality, brand, material, and automation levels. Understanding cost drivers and selection criteria helps businesses optimize productivity while managing budgets.

Key Factors Affecting Fish Cutting Machine Prices

Machine Type & Functionality

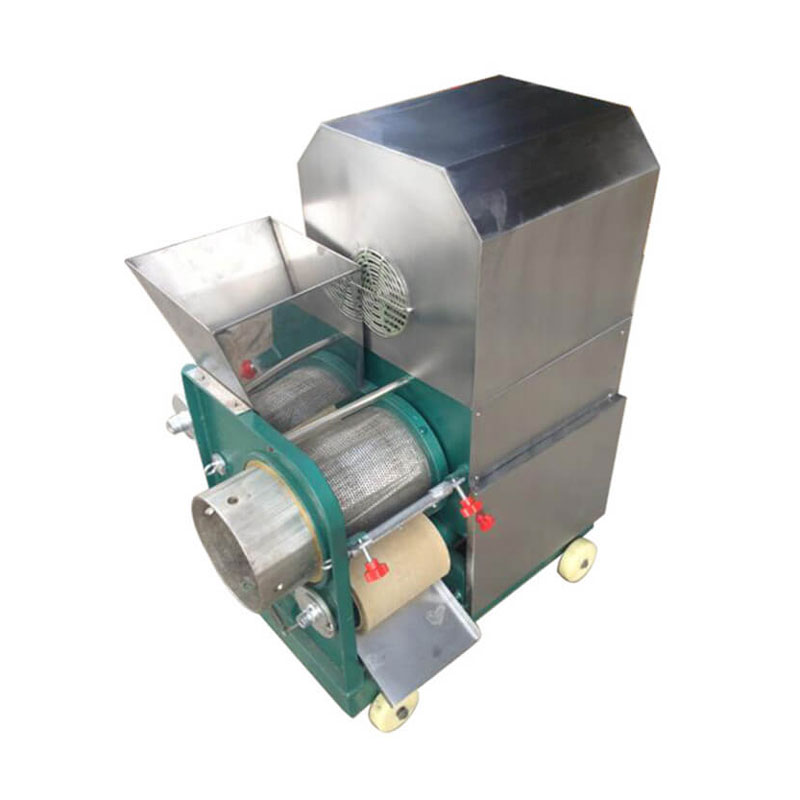

- Manual Cutting Machines : Lower cost (USD $540–$1,440), suitable for small-scale workshops or low-volume operations.

- Semi-Automatic Machines : Mid-range pricing (USD $2,700–$5,400), featuring basic automation like fixed-width cutting.

- Fully Automatic Fish Cutting Machines : Higher cost (USD $9,000–$46,000+), offering high-speed cutting, portioning, and deboning for large-scale production.

Material & Durability

- Models with food-grade stainless steel (FDA-compliant) are more durable and hygienic, often priced 10–20% higher than standard materials.

Automation & Precision

- Machines with automated cutting systems (e.g., laser-guided or AI vision) command premium prices (up to USD $60,000+), but boost accuracy and throughput by 30–50%.

Brand & Support

- International brands like Hobart or Jenny (USD $20,000–$120,000+) offer robust technical support and warranties.

- Domestic brands (e.g., Kemei , Xinhong ) provide cost-effective options (USD $4,000–$20,000).

Cost-Effective Buying Considerations

Production Scale : Small businesses may opt for semi-automatic models, while large factories require high-throughput equipment (e.g., fully automatic segmenters).

Maintenance Costs : Choose machines with modular designs for easy part replacement, reducing downtime.

Energy Efficiency : Models with energy-efficient motors (e.g., 20% lower power consumption) offset initial costs over time.

Market Trends & Price Fluctuations

Smart Automation : AI-integrated machines see annual price hikes of 5–10%, but productivity gains often justify the investment.

Customization : Specialized models for species like salmon or cod may add 15–25% to base prices.

Maintenance & Cost Control Tips

Schedule preventive maintenance (blade replacement, lubrication) to extend lifespan and reduce unexpected expenses.

Opt for suppliers offering extended warranties or discounted spare parts to lower long-term costs.

Conclusion

Fish cutting machine prices depend on operational needs and investment priorities. Balancing upfront costs with long-term efficiency gains ensures optimal ROI. By selecting cost-effective, high-performance models and prioritizing maintenance, businesses can enhance aquatic processing productivity and profitability.

Fish Speed Cleaning Machine

Fish Speed Cleaning Machine Fish Deboner Machine

Fish Deboner Machine Fish Cutting Machine

Fish Cutting Machine Fish Scaler Machine

Fish Scaler Machine Chicken Feet Cutting Machine

Chicken Feet Cutting Machine Bowl Cutter

Bowl Cutter Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Automatic Chicken Cutting Machine

Automatic Chicken Cutting Machine Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine Frozen Meat Cube Cutting Machine

Frozen Meat Cube Cutting Machine Automatic Sardine Canning Line Equipment

Automatic Sardine Canning Line Equipment  Sausage Automatic Double Wire Binding Machine

Sausage Automatic Double Wire Binding Machine Portable Flake Ice Machine

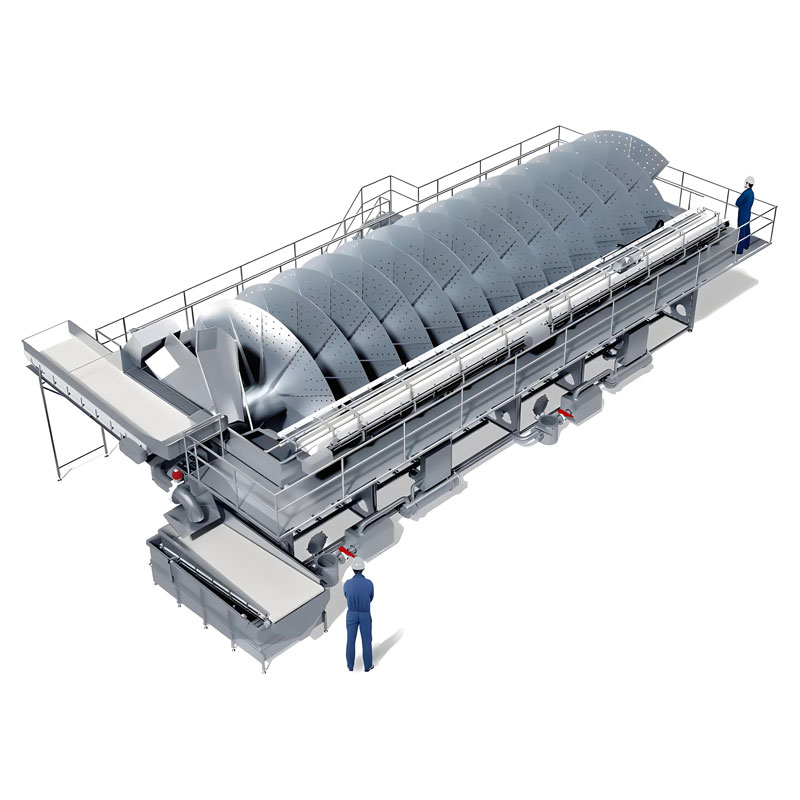

Portable Flake Ice Machine Salmon Processing Line

Salmon Processing Line Model 200 Frequency Conversion High Speed Chopper

Model 200 Frequency Conversion High Speed Chopper Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line