Electric Meat Slicer Machine - Chinese Manufacturer, Factory, Supplier

When it comes to electric meat slicer machines, they are indispensable tools for both home and commercial kitchens. These machines offer a convenient way to slice meats, cheeses, bread, and vegetables with precision and ease. Here's a detailed overview of what you should know about electric meat slicers:

Key Features to Consider

Power and Performance: Look for slicers with robust motors that can handle various types of food efficiently. For instance, powerful motors ensure smooth cutting even with thick or frozen meats.

Blade Quality: High-quality stainless steel blades are durable and resistant to corrosion. Models like the VEVOR commercial slicer feature chrome-plated blades for sharpness and longevity.

Adjustable Thickness: The ability to adjust slice thickness is crucial for achieving desired results. Machines like the Continental Electric Professional Series allow for adjustable thickness settings, making them versatile for different foods.

Safety Features: Safety interlocks and blade guards are essential for preventing accidents. Models such as the VEVOR bone saw slicer include multiple protective devices to safeguard users.

Ease of Cleaning: Removable parts and easy-to-clean designs make maintenance simpler. The Befen manual frozen meat slicer features easy cleaning and long-lasting stainless steel components.

Benefits of Using an Electric Meat Slicer

Healthier Options: By slicing your own meats and cheeses, you can avoid preservatives found in store-bought products, making it a healthier choice.

Cost-Effective: Buying whole meats and slicing them at home can reduce grocery expenses and provide more slices per batch.

Versatility: Electric slicers are not limited to meats; they can also slice vegetables, fruits, and bread, making them a versatile kitchen tool.

Popular Models

| Model | Price | Features |

|---|---|---|

| KWS Premium Electric Meat Slicer | $356.15 | Powerful 200W motor, adjustable thickness, stainless steel blade |

| VEVOR Commercial Meat Slicer | $129.99 | 240W motor, adjustable thickness, chrome-plated blade |

| Befen Manual Frozen Meat Slicer | $69.99 | Durable stainless steel, easy to clean and maintain |

Choosing the Right Electric Meat Slicer

When selecting an electric meat slicer, consider the type of products you plan to slice, the frequency of use, and the desired thickness settings. For commercial use, automatic slicers with high-capacity motors are recommended. For home use, semi-automatic or manual slicers may suffice.

Maintenance and Safety Tips

Regular Cleaning: Ensure all parts are cleaned thoroughly after use to maintain hygiene and extend the machine's lifespan.

Safety Precautions: Always use protective guards and follow safety guidelines to prevent accidents.

Whether you're a home chef or a commercial chef, electric meat slicers can enhance your cooking experience by providing precise and efficient slicing capabilities. With the right model, you can enjoy healthier, cost-effective, and versatile food preparation

Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Electric Cooked Meat Slicer

Electric Cooked Meat Slicer Frozen Meat Slicer

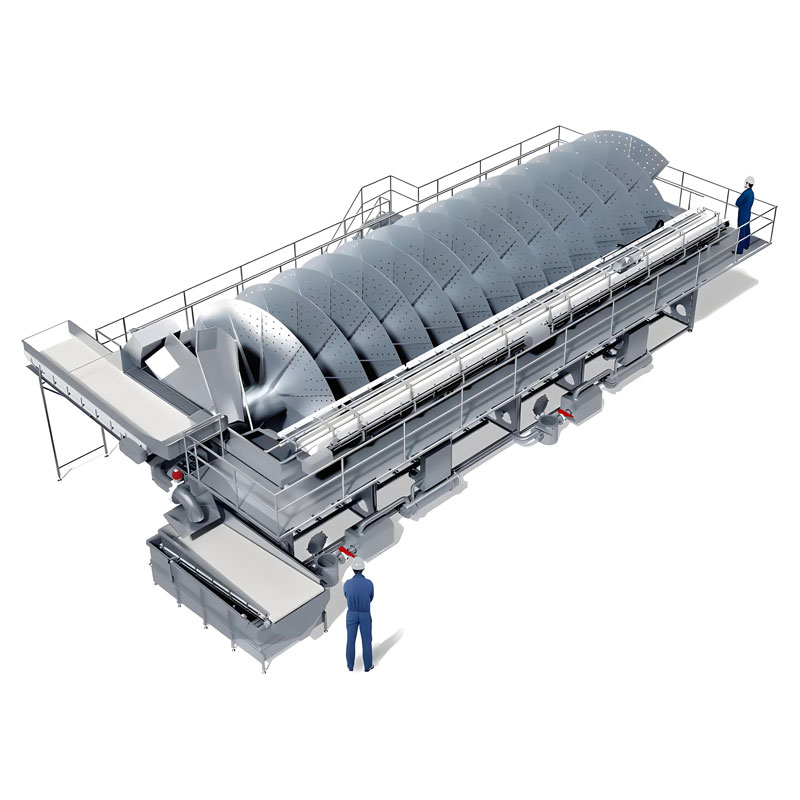

Frozen Meat Slicer Fish Meal Production Line

Fish Meal Production Line Meat Shredder Machine

Meat Shredder Machine Salmon Processing Line

Salmon Processing Line Tomato Sauce Machine

Tomato Sauce Machine Meat Cuber Machine

Meat Cuber Machine Chicken Feet Cutting Machine

Chicken Feet Cutting Machine YL-W-04 Commercial Water Purification Equipment

YL-W-04 Commercial Water Purification Equipment Meat Dicers

Meat Dicers