Commercial Meat Stuffer - Chinese Manufacturer, Factory, Supplier

A commercial meat stuffer is a heavy-duty appliance designed for high-volume sausage making and meat processing in professional kitchens, butcher shops, and food manufacturing facilities. Unlike standard home-use models, these industrial-grade machines feature robust construction with food-grade stainless steel components, powerful motors (0.5HP to 2HP), and large-capacity hoppers (5L to 50L) to handle continuous operation.

Key Applications & Benefits

This specialized equipment streamlines the production of sausages, salami, and cured meats by ensuring precise stuffing consistency. Vertical stuffer models with hydraulic pressure systems minimize air pockets, while horizontal machines excel at high-speed production. Commercial-grade units often include multiple nozzle attachments (10-15mm diameters) for creating various sausage types and meat fillings. NSF-certified models meet strict food safety standards, making them ideal for USDA-compliant operations.

Technical Specifications Matter

When selecting a commercial meat grinder and stuffer combo, prioritize features like:

Corrosion-resistant 304 stainless steel construction

Gear-driven transmission systems for durability

Pressure relief valves for overload protection

Easy-disassembly designs with dishwasher-safe parts

Warranty coverage (minimum 1-year commercial warranty)

Buying Considerations

For businesses searching "heavy-duty meat stuffer near me" or "commercial sausage stuffer supplier", focus on energy-efficient models (110V/220V options) with CE/ETL certifications. Top-rated brands like LEM Products, Weston, and Hakka offer commercial meat stuffers with throughput capacities ranging from 200-1,000 lbs/hour. Consider vacuum-packing compatible units for extended meat preservation.

Maintenance & Safety

Regular cleaning with food-safe sanitizers prevents bacterial growth. Always verify that electric meat stuffers have thermal overload protection and slip-resistant bases. Many commercial kitchens now opt for pneumatic meat stuffers for reduced energy consumption.

Sausage Stuffer Machine

Sausage Stuffer Machine Meat Stuffer Machine

Meat Stuffer Machine Automatic Twisting Quantitative Sausage Stuffer Machine

Automatic Twisting Quantitative Sausage Stuffer Machine Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Pasta Machine

Pasta Machine Chicken Slaughtering Machine

Chicken Slaughtering Machine Automatic Meat Mixer Machine

Automatic Meat Mixer Machine Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Automatic Sausage Linking Machine

Automatic Sausage Linking Machine Multifunctional Noodle Making Machine

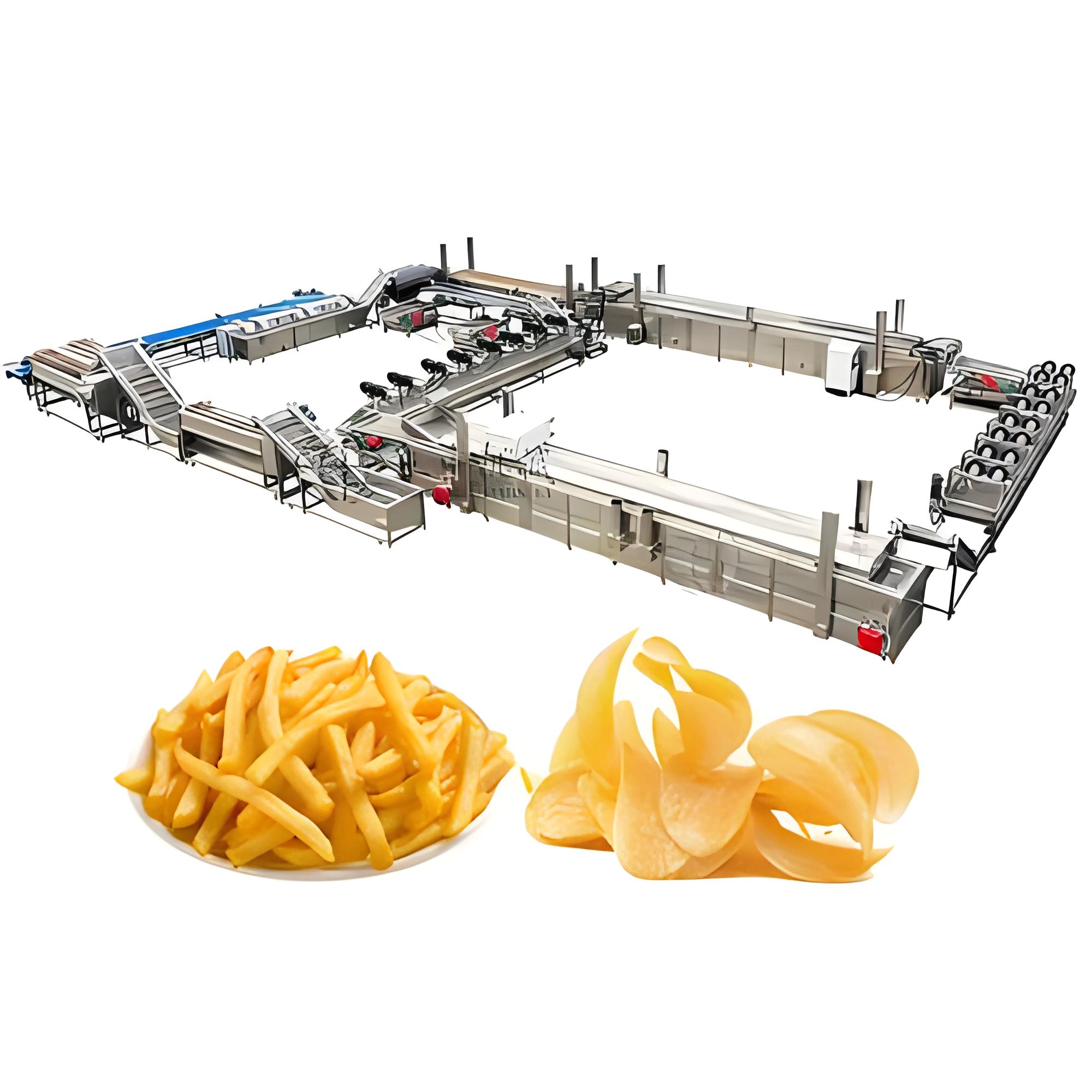

Multifunctional Noodle Making Machine French Fries Production Line

French Fries Production Line Automatic Sausage Clipper Machine

Automatic Sausage Clipper Machine