Commercial Meat Grinders - Chinese Manufacturer, Factory, Supplier

Commercial meat grinders are essential machines for processing meat in large quantities, making them indispensable for butcher shops, supermarkets, and meat processing plants. These grinders are designed to handle continuous, heavy-duty use, efficiently converting whole cuts of meat into ground meat for sausages, burgers, and other processed products. Equipped with high-powered motors and precision-engineered blades, commercial meat grinders deliver consistent grinding performance, maintaining the freshness and texture of the meat while ensuring hygiene and safety standards are met.

At our manufacturing facility, we specialize in producing a wide range of high-quality commercial meat grinders that are built to last. Our grinders feature customizable options for blade sizes and grinding capacities to suit the specific needs of different businesses. Made from durable stainless steel, our machines are easy to clean and maintain, with safety features designed to protect operators. We are committed to excellence, and our rigorous quality control processes ensure that each machine meets industry standards.

Whether you need a small unit for a boutique butcher shop or a large-scale grinder for an industrial meat plant, our equipment delivers consistent results. With a focus on innovation and customer satisfaction, we continue to provide reliable solutions to the global food processing industry.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Flake Ice Machine

Flake Ice Machine Brine Injector

Brine Injector Kimchi Production Line

Kimchi Production Line Automatic Sardine Canning Line Equipment

Automatic Sardine Canning Line Equipment  Automatic Cooked Meat Slicing Machine

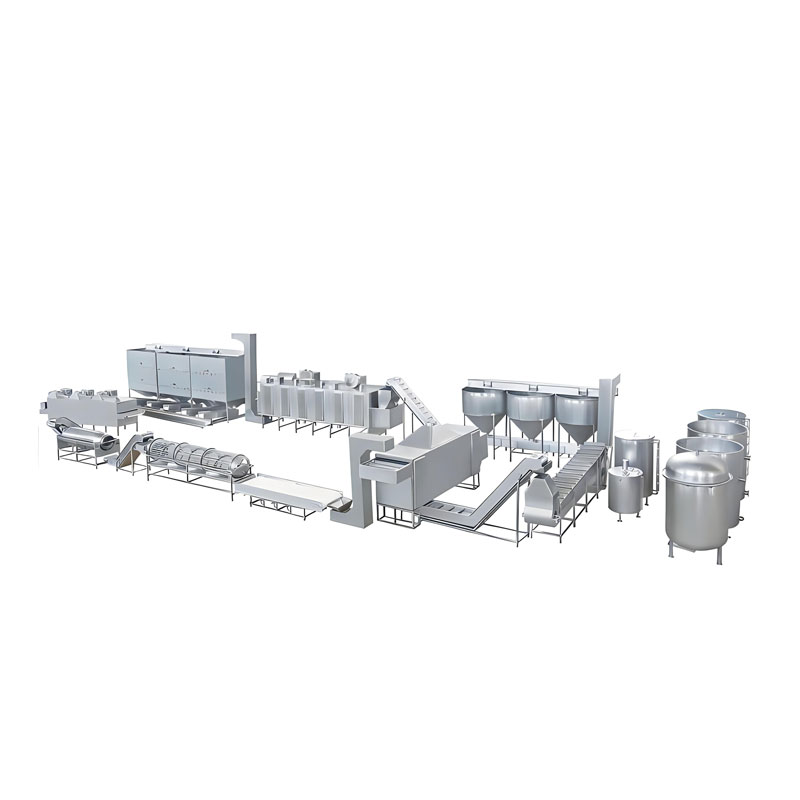

Automatic Cooked Meat Slicing Machine Meat Processing Line Equipment

Meat Processing Line Equipment YL-W-03 Commercial Water Purification Equipment

YL-W-03 Commercial Water Purification Equipment Tofu Production Line

Tofu Production Line