Commercial Ice Flaker - Chinese Manufacturer, Factory, Supplier

Imagine the myriad applications, from the pristine presentation of seafood on a market stall to the critical temperature regulation in a bustling medical facility – flake ice is an unsung hero in numerous industries. Its unique, thin, and malleable consistency offers superior cooling and coverage compared to other ice formats. So, you're considering harnessing this versatile resource, and the pivotal question arises: what is the Flake Ice Machine Price? Let's embark on an exploration of this crucial aspect, illuminating the factors that shape the fiscal contours of these indispensable appliances.

The Flake Ice Machine Price is not a monolithic entity; rather, it's a spectrum influenced by a confluence of variables. The machine's production capacity, often measured in kilograms or pounds per day, is a primary determinant. Higher capacity units, capable of generating substantial quantities of flake ice, will naturally command a more significant investment. Furthermore, the sophistication of the internal components, the robustness of the materials employed in its construction (often stainless steel for hygiene and longevity), and the integration of advanced control systems all contribute to the overall cost.

Considering the global manufacturing landscape can unveil advantageous opportunities. The china Flake Ice Machine factory sector has burgeoned, offering a plethora of options ranging from compact, entry-level machines to expansive, industrial-grade systems. These factories often leverage streamlined production processes and competitive labor costs, potentially translating to more accessible price points for consumers worldwide. However, prudent evaluation remains paramount. While a lower initial Flake Ice Machine Price might seem alluring, it's essential to scrutinize factors such as build quality, energy efficiency, and after-sales support to ensure a sound long-term investment.

Ultimately, the decision to acquire a flake ice machine transcends the mere monetary outlay. It's an investment in operational efficiency, product preservation, and enhanced presentation. By meticulously considering your specific needs, evaluating the offerings from various manufacturers, including those within the china Flake Ice Machine factory ecosystem, and prioritizing long-term value, you can confidently select a machine that not only aligns with your budgetary parameters but also delivers enduring performance and a tangible return on your investment. Embrace the chill, and unlock the myriad benefits that flake ice can bring to your endeavors.

Flake Ice Machine

Flake Ice Machine Fish Cutting Machine

Fish Cutting Machine Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Electric Cooked Meat Slicer

Electric Cooked Meat Slicer Meat Dicers

Meat Dicers Pork Skin Removing Machine

Pork Skin Removing Machine Pelmeni Making Machine

Pelmeni Making Machine Big Chicken Feet Peeling Machine

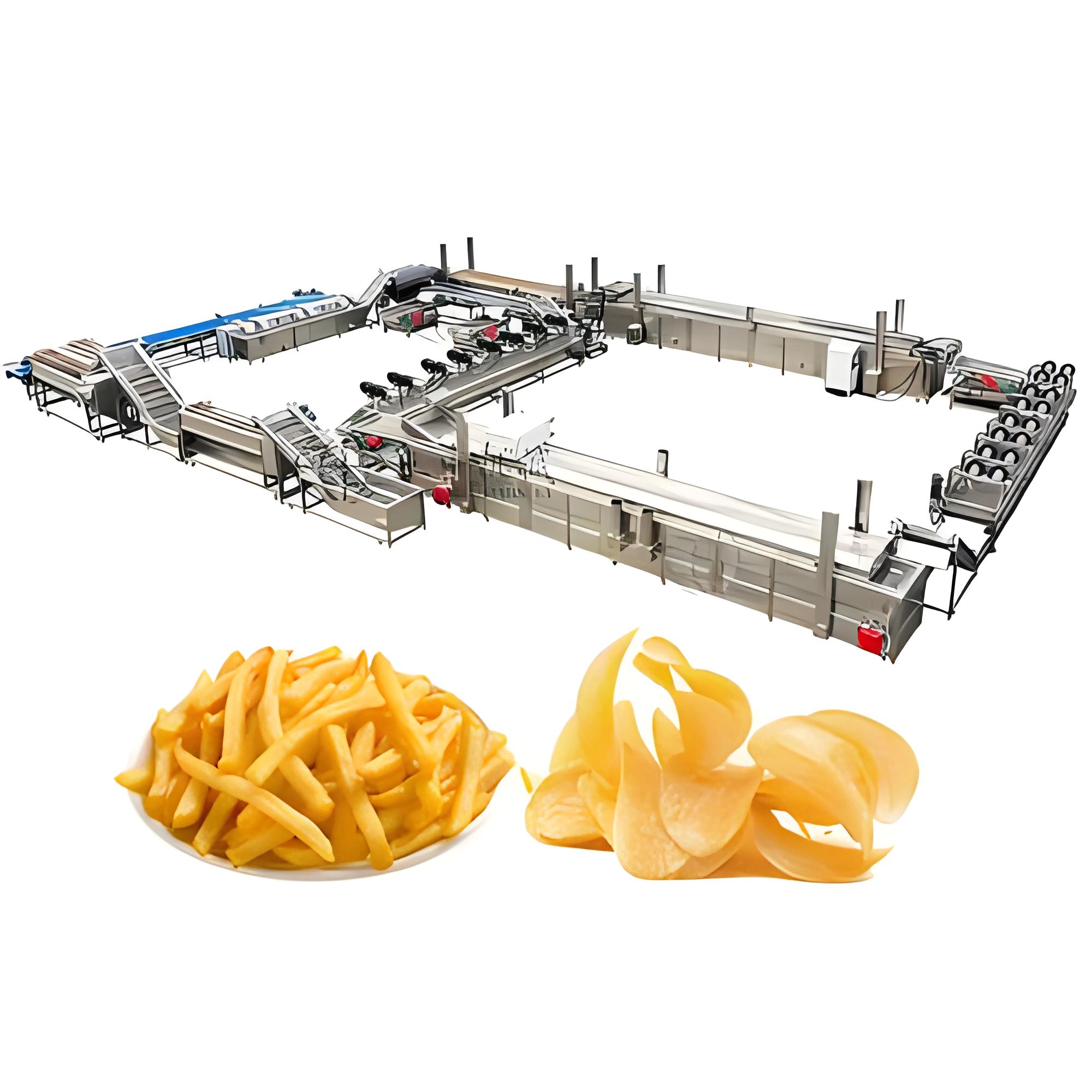

Big Chicken Feet Peeling Machine French Fries Production Line

French Fries Production Line