Commercial Freeze Drying Machine China - Chinese Manufacturer, Factory, Supplier

The global food processing industry has witnessed a significant rise in the use of freeze-drying technologies, with the Commercial Freeze Drying Machine China emerging as a leading solution for businesses seeking to preserve the quality and nutritional value of food. Freeze-drying, a process that removes moisture from food products while maintaining their structure, flavor, and nutrients, has gained popularity across sectors such as food, pharmaceuticals, and cosmetics. As a result, Chinese manufacturers have become key players in providing high-performance freeze-drying machines that cater to a wide array of commercial needs.

A Commercial Freeze Drying Machine China is engineered to handle the complex freeze-drying process, which involves freezing the product, reducing its pressure, and then sublimating the ice into vapor. This sophisticated technology ensures that the food retains its original texture and taste, with minimal loss of nutrients. Chinese manufacturers have continually refined this process, incorporating state-of-the-art sensors, automated controls, and energy-efficient systems that allow for precise control over every stage of the freeze-drying cycle.

The main advantage of sourcing a Commercial Freeze Drying Machine China lies in the balance between cost-effectiveness and technological advancement. China’s manufacturing capabilities allow for the production of high-quality, robust freeze-drying machines at a fraction of the cost compared to other regions. This affordability makes it accessible to small, medium, and large-scale businesses alike, while still delivering superior results. The machines are constructed with durable, food-grade materials, ensuring that they meet international standards for hygiene and safety.

Furthermore, Commercial Freeze Drying Machine China offers exceptional scalability. Whether a company is looking to process small batches for premium products or large-scale production for mass distribution, Chinese manufacturers provide machines that are customizable to meet specific production needs. Many models are equipped with multi-functional features, allowing for flexibility in the types of products that can be freeze-dried, such as fruits, vegetables, meats, and even pharmaceuticals.

Another key benefit is the energy efficiency of Commercial Freeze Drying Machine China. With increasing global concern over energy consumption, these machines are designed to minimize energy use without compromising performance. Advanced systems allow businesses to optimize freeze-drying cycles, reducing both energy costs and environmental impact.

In conclusion, Commercial Freeze Drying Machine China provides a powerful solution for businesses looking to enhance their product offerings with high-quality freeze-dried goods. The combination of advanced technology, scalability, cost-effectiveness, and energy efficiency makes these machines indispensable tools for modern food processors and manufacturers worldwide.

Industrial Microwave Drying Machine

Industrial Microwave Drying Machine Rotary Drum Potato Chips Seasoning Machine

Rotary Drum Potato Chips Seasoning Machine Pasta /Macaroni Making Line

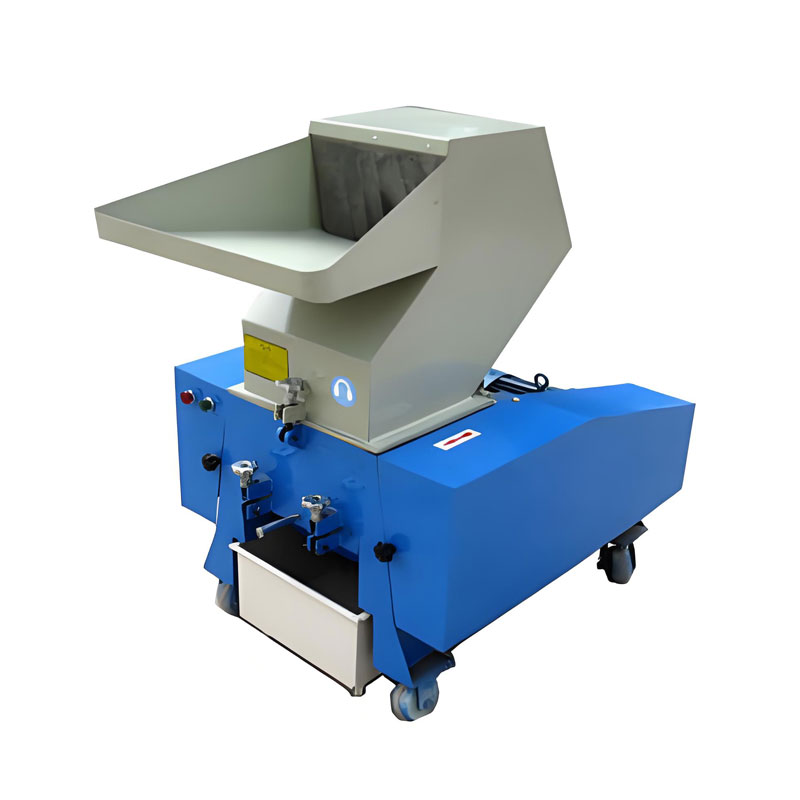

Pasta /Macaroni Making Line Bone Crusher Machine

Bone Crusher Machine Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine Sausage Automatic Double Wire Binding Machine

Sausage Automatic Double Wire Binding Machine Meat Dicers

Meat Dicers Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Automatic Twisting Quantitative Sausage Stuffer Machine

Automatic Twisting Quantitative Sausage Stuffer Machine