Commercial Flake Ice Making Machine - Chinese Manufacturer, Factory, Supplier

In the competitive landscape of food service and industrial applications, the demand for high-quality ice is ever-present. A Commercial Flake Ice Making Machine stands out as an indispensable asset, delivering superior performance and reliability. These machines are engineered to produce large quantities of flake ice, which is ideal for a myriad of uses, from preserving perishables to cooling beverages. The versatility of this equipment makes it a cornerstone in industries such as hospitality, healthcare, and fisheries.

What sets a Commercial Flake Ice Making Machine apart is its ability to generate soft, pliable ice that conforms effortlessly to various applications. Unlike traditional ice cubes, flake ice’s malleable nature ensures optimal cooling without damaging delicate items. This makes it particularly valuable in sushi bars, seafood markets, and medical facilities where temperature control is paramount. The machine’s advanced thermodynamic cycle ensures energy efficiency, reducing operational costs while maintaining consistent ice production.

The design of a Commercial Flake Ice Making Machine incorporates cutting-edge technology to minimize maintenance and maximize longevity. Features such as automated cleaning cycles and corrosion-resistant components ensure that the equipment remains in peak condition, even under heavy usage. Additionally, the compact footprint of many models allows for seamless integration into existing kitchen layouts or industrial setups, optimizing space utilization.

For businesses aiming to elevate their service standards, investing in a Commercial Flake Ice Making Machine is a strategic decision. The machine’s capacity to produce large volumes of ice on demand ensures that operations run smoothly, especially during peak seasons. Whether it’s for cooling concrete in construction or enhancing the presentation of fresh produce, the applications are boundless.

In summary, the Commercial Flake Ice Making Machine is more than just an ice generator; it is a testament to innovation and practicality. Its ability to deliver consistent, high-quality ice while adhering to stringent efficiency standards makes it an invaluable asset for any enterprise that values precision and performance.

Portable Flake Ice Machine

Portable Flake Ice Machine Crushed Ice Machine

Crushed Ice Machine Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Electric Cooked Meat Slicer

Electric Cooked Meat Slicer Flake Ice Machine

Flake Ice Machine Frozen Meat Slicer

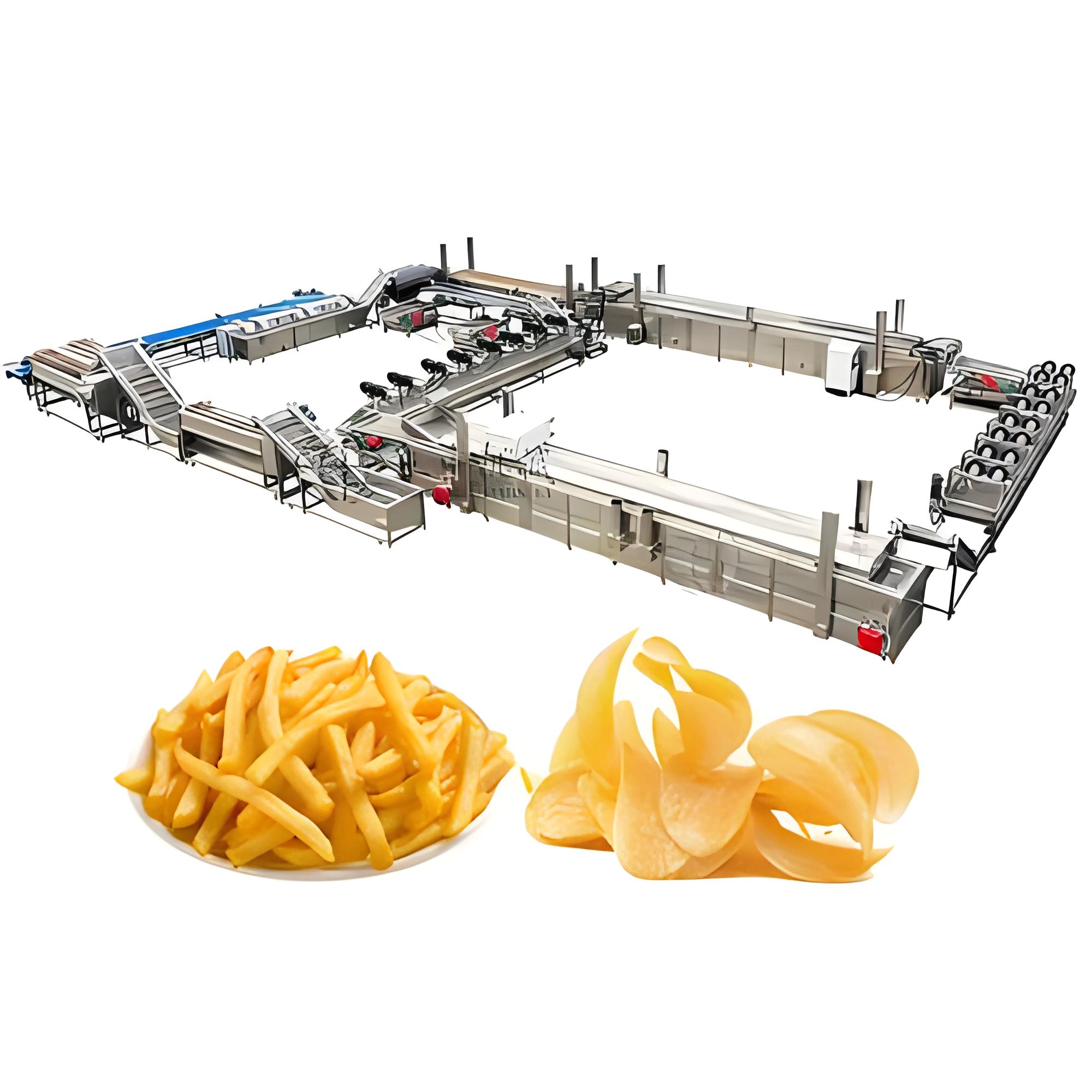

Frozen Meat Slicer French Fries Production Line

French Fries Production Line Chicken Slaughtering Machine

Chicken Slaughtering Machine Automatic Sausage Peeling Machine

Automatic Sausage Peeling Machine Automatic Sausage Linking Machine

Automatic Sausage Linking Machine YL-W-06 Commercial Water Purification Equipment

YL-W-06 Commercial Water Purification Equipment Industrial Frozen Meat Slicing Machine

Industrial Frozen Meat Slicing Machine Automatic Sardine Canning Line Equipment

Automatic Sardine Canning Line Equipment  Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine