China Meat Equipment - Chinese Manufacturer, Factory, Supplier

The global meat processing industry relies heavily on advanced machinery to meet rising demand for quality, efficiency, and safety. At the forefront of this evolution is China Meat Equipment , a sector renowned for its innovation, precision, and adaptability. From state-of-the-art slaughterhouse systems to cutting-edge packaging solutions, China’s meat processing technology has become indispensable to industries worldwide.

China Meat Equipment manufacturers are pioneers in integrating smart automation and precision engineering. Their machinery often features mechanized disassembly systems that reduce labor costs while enhancing product consistency. Advanced thermal processing units, engineered with integrated hygienic designs , ensure compliance with stringent food safety protocols. These systems are built to handle high-volume operations without compromising on sanitation—a critical factor in global supply chains.

One hallmark of China Meat Equipment is its adaptability to diverse market needs. Whether for halal-certified facilities or premium gourmet butcheries, these systems offer bespoke configurations tailored to regional regulations and consumer preferences. The use of modular frameworks allows for seamless upgrades, ensuring equipment remains future-ready as industry standards evolve.

Sustainability is another pillar of China’s meat processing innovation. Leading manufacturers prioritize energy-efficient designs and eco-friendly materials, minimizing environmental footprints. For instance, recirculating chilling systems optimize water usage, while AI-driven waste management modules reduce operational inefficiencies. Such advancements align with global trends toward ethical production, positioning China Meat Equipment as a leader in eco-conscious manufacturing.

The global appeal of China Meat Equipment stems from its blend of affordability and reliability. High-quality stainless steel components and rigorous stress-testing ensure longevity, while post-installation support networks provide technical assistance across continents. This combination has made Chinese machinery a go-to solution for both small-scale processors and multinational corporations.

Looking ahead, China Meat Equipment continues to push boundaries with emerging technologies like blockchain-enabled traceability systems and IoT-connected monitoring tools. These innovations not only enhance transparency but also streamline compliance with international certifications such as HACCP and ISO 22000.

In conclusion, China Meat Equipment stands as a testament to the country’s engineering prowess and commitment to global food security. By prioritizing innovation, sustainability, and customer-centric design, it has solidified its role as a cornerstone of modern meat processing. As industries worldwide seek efficient, scalable solutions, the advancements from China promise to redefine the future of protein production.

Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Stuffed Meatball Machine

Stuffed Meatball Machine Meat Shredder Machine

Meat Shredder Machine Vacuum Meat Tumbler

Vacuum Meat Tumbler Meat Bun Machine

Meat Bun Machine Bowl Cutter

Bowl Cutter Model 330 Frequency Conversion High Speed Chopper

Model 330 Frequency Conversion High Speed Chopper Model 200 Frequency Conversion High Speed Chopper

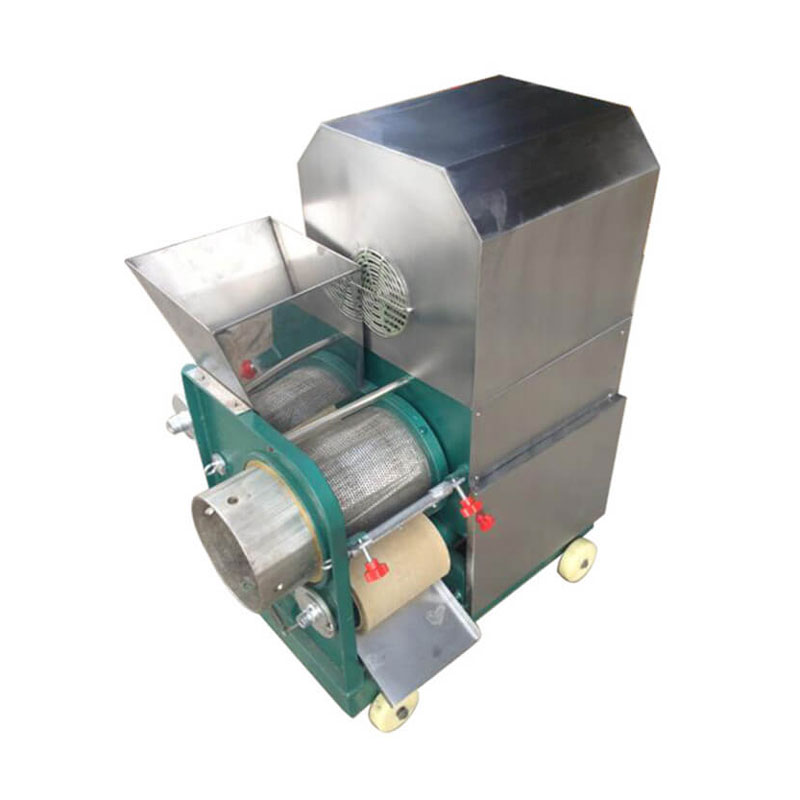

Model 200 Frequency Conversion High Speed Chopper Fish Deboner Machine

Fish Deboner Machine Automatic Sausage Linking Machine

Automatic Sausage Linking Machine Automatic Meatball Production Line

Automatic Meatball Production Line