Chili Sauce Machine China - Chinese Manufacturer, Factory, Supplier

Chili Sauce Machine China has emerged as a linchpin in the global condiment industry, revolutionizing how artisanal and commercial producers craft their signature blends. As the epicenter of advanced food processing technology, China’s manufacturers have mastered the alchemy of precision engineering and culinary expertise, delivering machinery that balances tradition with hyper-efficiency. These state-of-the-art Chili Sauce Machine China systems integrate automated ingredient dosing, real-time viscosity control, and sterile filling mechanisms—ensuring consistency without compromising artisanal authenticity.

The ascendancy of Chili Sauce Machine China lies in its adaptability. Whether scaling micro-batch fermentation or industrial-grade production, these machines offer modular configurations tailored to diverse heat profiles and texture requirements. Innovators in Guangdong and Shandong provinces, for instance, employ AI-driven sensors to optimize emulsification cycles, a testament to China’s precocity in smart manufacturing.

Moreover, sourcing a Chili Sauce Machine China guarantees cost-efficiency paired with rigorous compliance to international food safety protocols. Export-oriented designs feature corrosion-resistant alloys and seamless CIP (Clean-in-Place) systems, minimizing downtime while maximizing hygiene. For startups and conglomerates alike, investing in Chinese-engineered machinery isn’t merely pragmatic—it’s strategic.

In an era where consumers crave bold, authentic flavors, partnering with Chili Sauce Machine China providers ensures your product stands out. Their fusion of cutting-edge automation and bespoke customization cements China’s unassailable position as the global leader in condiment technology. Elevate your production; let innovation simmer.

Sauce Filling Machine

Sauce Filling Machine Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Centrifugal Dewatering Machine

Centrifugal Dewatering Machine Meat Pie Maker Machine

Meat Pie Maker Machine Dough Roller Machine

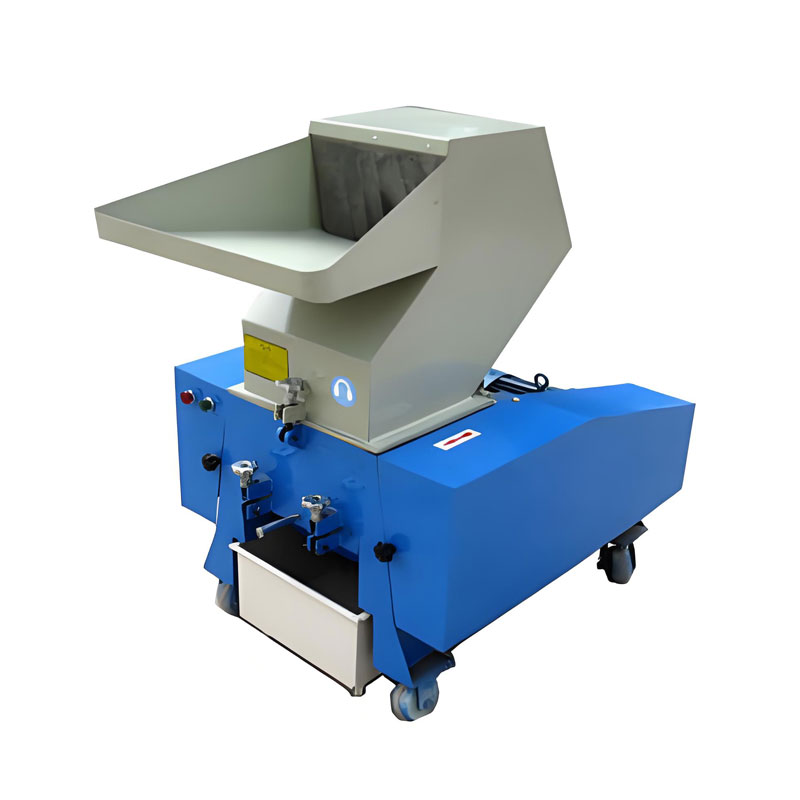

Dough Roller Machine Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Industrial Microwave Drying Machine

Industrial Microwave Drying Machine Cooking Drying Oven

Cooking Drying Oven Automatic Belt Frying Machine

Automatic Belt Frying Machine Pasta Machine

Pasta Machine