Chicken Slaughtering Machine China - Chinese Manufacturer, Factory, Supplier

The global poultry industry relies on efficiency, hygiene, and scalability to meet soaring demand—and automation sits at the heart of this mission. China has emerged as a trailblazer in designing chicken slaughtering machines, offering solutions that redefine speed, safety, and sustainability. From high-volume processing plants to niche organic farms, Meat Equipment China manufacturers are setting new benchmarks in poultry technology.

Precision Engineering for Modern Demands

At the forefront of this revolution is the China yuanlin factory, a hub of cutting-edge poultry processing systems. Their slaughtering machines integrate multi-stage automation, starting with AI-guided stunning systems that ensure ethical treatment and minimize stress-induced meat quality issues. Advanced rotary blade arrays and vacuum blood collection mechanisms follow, optimizing yield while adhering to halal or kosher certifications where required.

These machines also feature modular plucking systems with adjustable rubber fingers, capable of handling diverse bird sizes without damaging delicate skin—a critical factor for premium product lines. According to a 2023 industry report, facilities using Meat Equipment China solutions report a 20% reduction in processing time and a 15% increase in meat integrity compared to manual methods.

Hygiene and Compliance: Built-In Safeguards

Food safety is non-negotiable. The China yuanlin factory employs hygienic design protocols, using stainless steel alloys with antimicrobial coatings to resist bacterial buildup. Closed-loop water systems in scalding tanks reduce cross-contamination risks, while self-cleaning nozzles automate sanitation between batches. Such innovations align with global standards like ISO 22000 and EU meat processing directives, giving exporters a competitive edge.

Sustainability: Efficiency Meets Responsibility

China’s poultry machinery sector prioritizes eco-conscious practices. Energy-efficient motors and heat recovery systems in chicken slaughtering machines cut power consumption by up to 30%, as noted in a UN Sustainable Development case study. The China yuanlin factory further innovates by repurposing byproducts like feathers into biodegradable materials, aligning slaughterhouse operations with circular economy principles.

Customization for Diverse Markets

Flexibility defines Meat Equipment China. Whether catering to free-range poultry farms or large-scale industrial processors, manufacturers offer adaptable configurations. Quick-swap modules allow seamless transitions between different slaughtering methods, such as electrical stunning for standard markets or controlled-atmosphere systems for premium organic brands. This agility ensures compliance with regional regulations and consumer preferences worldwide.

Trust Through Technological Transparency

China’s dominance in poultry automation is backed by data-driven reliability. The China yuanlin factory equips machines with IoT sensors for real-time monitoring of parameters like blade sharpness and water temperature. Predictive maintenance alerts reduce downtime, while cloud-based analytics empower processors to optimize output. With certifications from NSF International and the Global Food Safety Initiative, these systems meet the highest trust benchmarks.

Conclusion

In an era where precision and ethics define consumer choices, chicken slaughtering machines from China offer an unmatched blend of innovation and compliance. From the visionary engineering of the China yuanlin factory to the scalable solutions of Meat Equipment China, these technologies empower processors to deliver quality, safety, and sustainability at scale. For businesses aiming to lead in the competitive poultry market, embracing Chinese expertise isn’t just strategic—it’s transformative.

Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine Poultry Slaughtering Line

Poultry Slaughtering Line Chicken Egg Peeling Machine

Chicken Egg Peeling Machine Chicken Feet Peeling Production Line

Chicken Feet Peeling Production Line Small Chicken Feet PeelingMachine

Small Chicken Feet PeelingMachine Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine Chicken Feet Cutting Machine

Chicken Feet Cutting Machine Automatic Chicken Cutting Machine

Automatic Chicken Cutting Machine Chicken Nugget Processing Line

Chicken Nugget Processing Line Chicken Processing Line

Chicken Processing Line Meat Grinding Machine

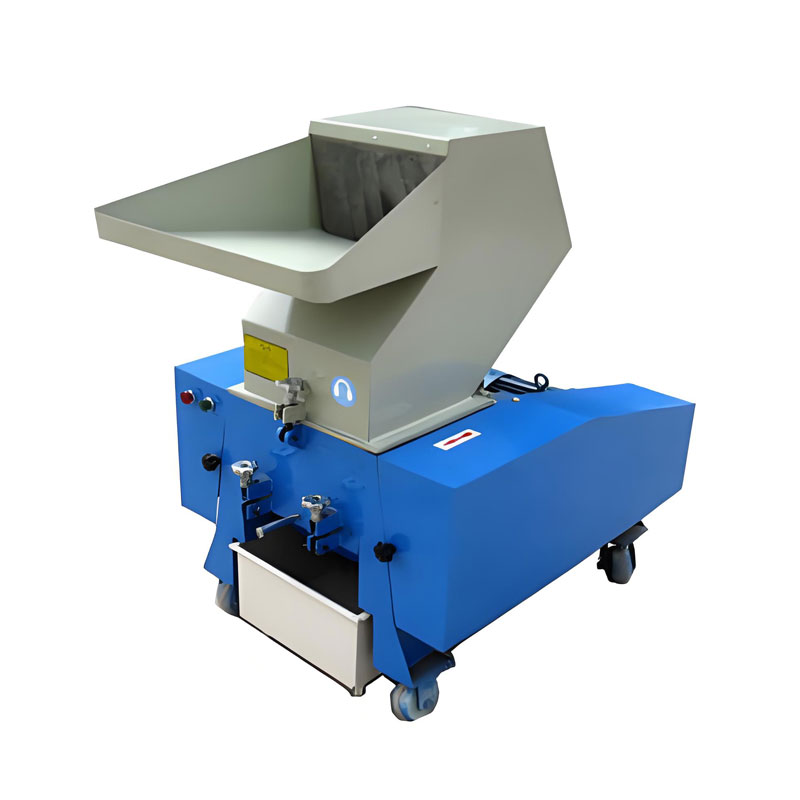

Meat Grinding Machine Meat Shredder Machine

Meat Shredder Machine Frozen Meat Ribs Dicing Machine

Frozen Meat Ribs Dicing Machine Sauce Filling Machine

Sauce Filling Machine Bean Product Production Line

Bean Product Production Line High-Speed Twisting Machine

High-Speed Twisting Machine Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Potato Chips Instant Freezer

Potato Chips Instant Freezer