Chicken Cutting Machine Cost - Chinese Manufacturer, Factory, Supplier

When considering the cost of a chicken cutting machine, several factors come into play. Prices can vary significantly depending on the machine's capacity, features, brand, and material quality. Typically, basic models designed for smaller operations may start at around $1,000, while more advanced industrial-grade machines, equipped with automation, precision cutting, and enhanced safety features, can exceed $10,000.

Beyond the initial purchase price, other costs such as maintenance, energy consumption, and possible replacement of parts should also be considered. Machines made from stainless steel may have a higher upfront cost, but their durability and ease of cleaning could reduce long-term expenses. In addition, brands with strong reputations for reliability may offer better customer support and warranties, potentially lowering costs related to repairs.

Investing in a high-quality chicken cutting machine can improve processing efficiency, reduce labor costs, and increase product consistency, making it a worthwhile consideration for poultry processors. Before purchasing, it's advisable to compare models, request quotes, and assess the specific needs of your operation to ensure you're getting the best value for your investment.

Chicken Soup Canned Production Line

Chicken Soup Canned Production Line French Fries Cutting Machine

French Fries Cutting Machine Automatic Chicken Canned Food Production Line

Automatic Chicken Canned Food Production Line Chicken Production Line

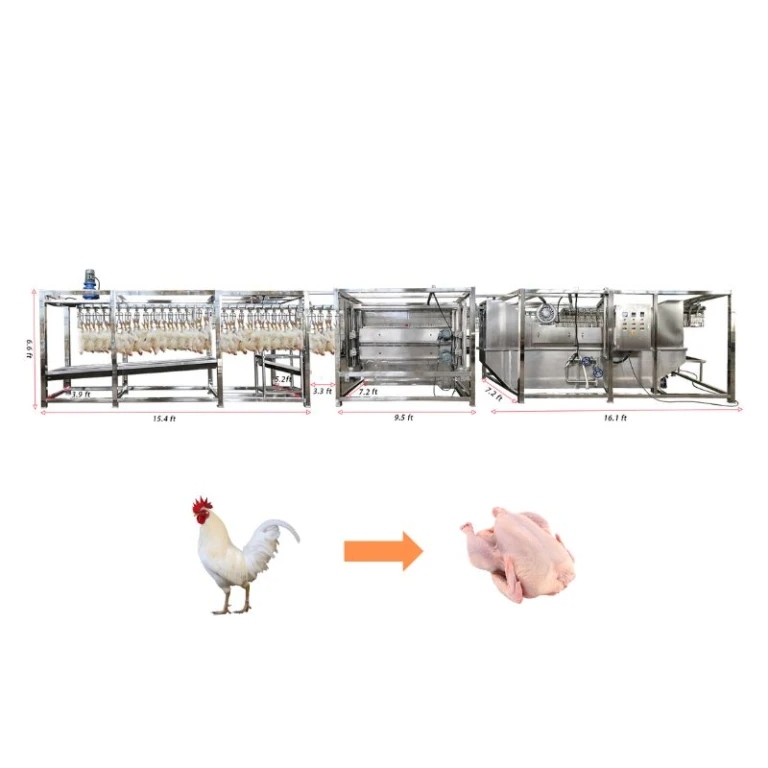

Chicken Production Line Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine Chicken Egg Peeling Machine

Chicken Egg Peeling Machine Fish Cutting Machine

Fish Cutting Machine Chicken Feet Peeling Production Line

Chicken Feet Peeling Production Line Small Chicken Feet PeelingMachine

Small Chicken Feet PeelingMachine Bowl Cutter

Bowl Cutter Remove The Machine

Remove The Machine Meat Shredding Machine

Meat Shredding Machine SC Series Bullet Ice Maker

SC Series Bullet Ice Maker Gizzard Peeling Machine

Gizzard Peeling Machine Automatic Rice Production Line

Automatic Rice Production Line Crushed Ice Machine

Crushed Ice Machine