Bone Saw Cutting Machine - Chinese Manufacturer, Factory, Supplier

In the intricate world of meat preparation, the Bone Saw Cutting Machine emerges as a quintessential apparatus, transforming the arduous task of cutting bones, frozen meat, and fish into a seamless operation. Manufactured by the esteemed China Yuanlin Factory, this equipment exemplifies a fusion of robust design and cutting-edge technology, catering to the exacting demands of butcher shops, slaughterhouses, and food processing facilities.

The Bone Saw Cutting Machine boasts a formidable stainless steel construction, a material revered for its resilience and adherence to rigorous food hygiene protocols. Its potent motor, often spanning 1.5kw to 4kw, propels a razor-sharp saw blade through the densest of osseous structures with remarkable alacrity. Safety is paramount; features like the saw band stabilizer and ergonomic safety lever mitigate risks, ensuring a secure and efficient workflow. This machine’s multifarious capabilities allow it to dissect everything from delicate poultry bones to substantial frozen cuts, delivering precision that minimizes waste and elevates productivity.

The China Yuanlin Factory has carved a niche as a paragon in the realm of meat processing machinery. Renowned for its meticulous craftsmanship, the factory integrates avant-garde technology into every Bone Saw Cutting Machine, ensuring longevity and peak performance. Their portfolio includes diverse models tailored to varying operational scales. The QH330, with its 1.5kw motor and 200mm cutting capacity, suits smaller enterprises, while the QH350, equipped with a 2.2kw motor, excels in high-throughput environments. Each unit is designed for facile maintenance, reinforcing reliability across years of service.

Beyond its technical prowess, the Bone Saw Cutting Machine offers pragmatic advantages. Its waterproof exterior and easily sanitized surfaces uphold impeccable hygiene standards, vital in food industry settings. The compact footprint optimizes space in bustling commercial kitchens, enhancing operational fluidity. Such attributes underscore its indispensability for professionals seeking to streamline processes and elevate output quality.

For meat processing connoisseurs, the Bone Saw Cutting Machine from the China Yuanlin Factory represents an investment in efficiency and excellence. This apparatus stands as a testament to superior engineering, harmonizing power, precision, and safety to meet the evolving needs of the culinary and food production sectors.

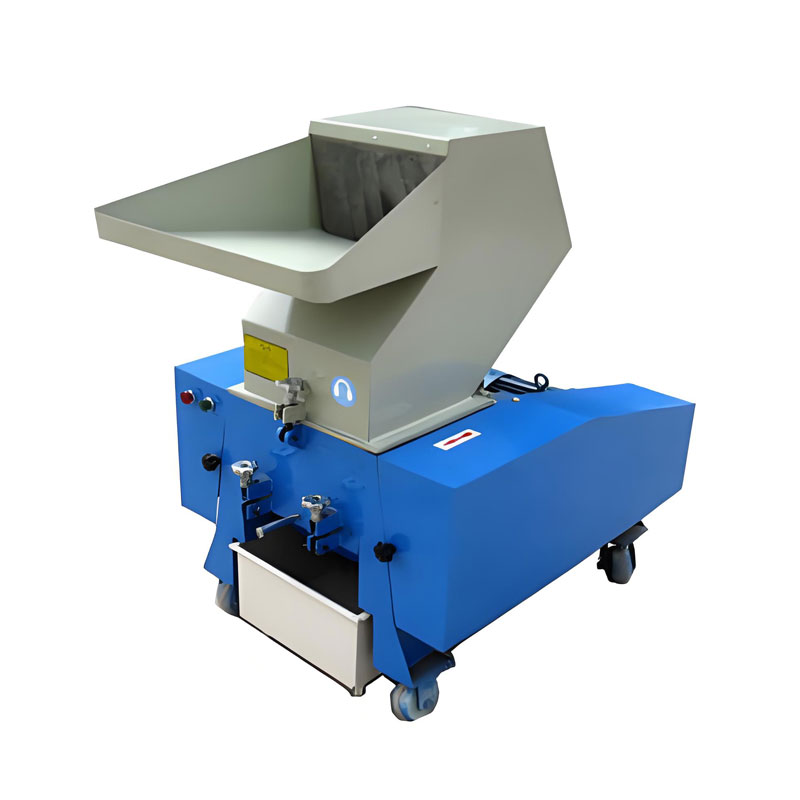

Automatic Bone Crushing Machine

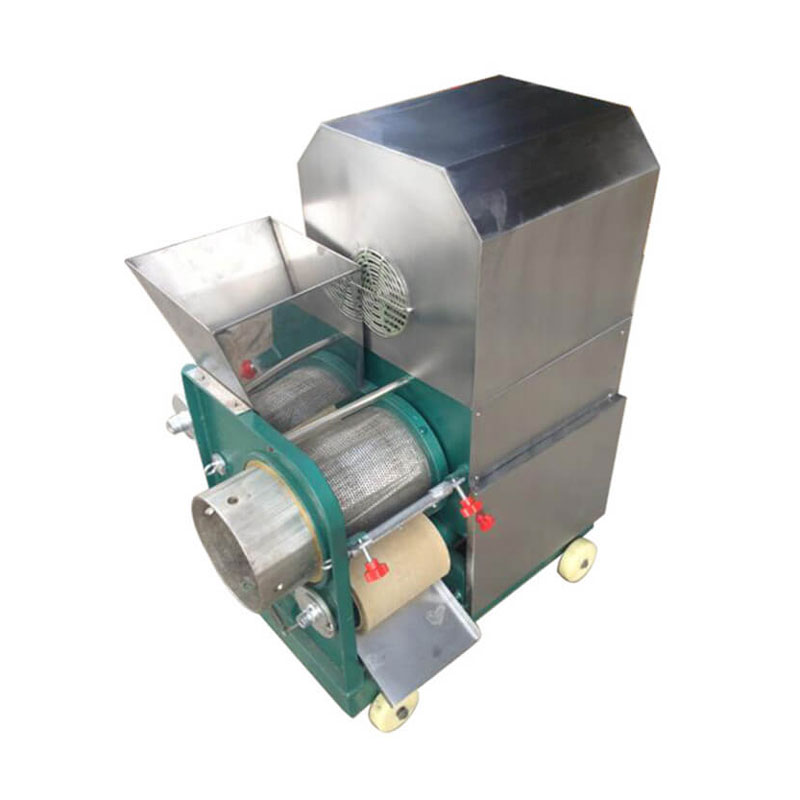

Automatic Bone Crushing Machine Fish Deboner Machine

Fish Deboner Machine Fish Cutting Machine

Fish Cutting Machine Chicken Feet Cutting Machine

Chicken Feet Cutting Machine Bone Crusher Machine

Bone Crusher Machine Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Automatic Chicken Cutting Machine

Automatic Chicken Cutting Machine Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine Frozen Meat Cube Cutting Machine

Frozen Meat Cube Cutting Machine Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine Commercial Stufed Meatball Forming Machine

Commercial Stufed Meatball Forming Machine Household Meat Grinder

Household Meat Grinder Crushed Ice Machine

Crushed Ice Machine Vacuum Meat Tumbler

Vacuum Meat Tumbler Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Frozen Meat Slicer

Frozen Meat Slicer Tomato Sauce Machine

Tomato Sauce Machine Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine