Best Sausage Making Equipment - Chinese Manufacturer, Factory, Supplier

Sausage making is a culinary craft that demands precision, skill, and the finest tools. The quality of the apparatus employed can profoundly influence the texture, flavor, and overall triumph of the sausages. For both novice enthusiasts and seasoned butchers, investing in the Best Sausage Making Equipment is not merely a choice—it's a necessity. This guide explores the critical components of superior sausage making machinery, spotlighting the features that distinguish them and the pivotal role of esteemed manufacturers like the China Yuanlin Factory in delivering exceptional quality.

Essential Components of Sausage Making Equipment

Grinders: A premier meat comminutor forms the bedrock of sausage production. Top models boast razor-sharp blades and robust motors, effortlessly reducing even the most sinewy cuts to a uniform consistency. Their design prioritizes hygiene, with easy disassembly for thorough cleaning. This ensures both durability and the preservation of meat quality—a non-negotiable for exquisite sausages.

Stuffers: The finest sausage encasing devices operate with seamless precision, eliminating air pockets that could mar the final product. These machines accommodate an array of casing diameters, offering versatility for diverse sausage styles. Options range from manual fillers, which afford meticulous control, to electric variants that excel in speed and uniformity, catering to high-volume needs.

Mixers: Achieving a harmonious blend of spices and ingredients is paramount. Elite mixers feature capacious bowls and vigorous paddles, guaranteeing an even distribution that elevates flavor profiles. Consistency is king in sausage making, and these machines deliver it without compromise.

Technical Superiority

Exceptional sausage making equipment is defined by its construction. Food-grade stainless steel reigns supreme, offering unparalleled resistance to corrosion and contamination while ensuring longevity. Power specifications vary—smaller grinders might wield 0.5 horsepower, while industrial behemoths exceed 1 HP, tailored to the scope of production. Such technical prowess translates into tangible efficiency and reliability.

China Yuanlin Factory: A Standard of Excellence

The China Yuanlin Factory stands as a titan in the realm of Best Sausage Making Equipment. Renowned for innovative engineering and rigorous quality assurance, their products meet stringent global standards. This dedication positions them as a trusted ally for professionals seeking dependable, high-performing tools.

Sausage Stuffer Machine

Sausage Stuffer Machine Automatic Sausage Peeling Machine

Automatic Sausage Peeling Machine Automatic Sausage Clipper Machine

Automatic Sausage Clipper Machine Sausage Tying Machine

Sausage Tying Machine Automatic Sausage Linking Machine

Automatic Sausage Linking Machine Hydraulic Sausage Filling Machine

Hydraulic Sausage Filling Machine Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler Automatic Twisting Quantitative Sausage Stuffer Machine

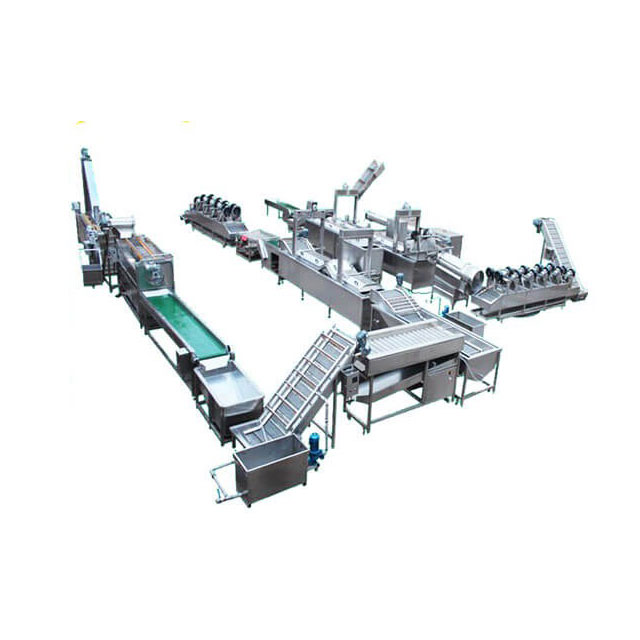

Automatic Twisting Quantitative Sausage Stuffer Machine Sausage Processing Line

Sausage Processing Line Sausage Automatic Double Wire Binding Machine

Sausage Automatic Double Wire Binding Machine Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Meatball Forming Machine

Meatball Forming Machine Paste Grinding Machine

Paste Grinding Machine Frozen French Fries Production Line

Frozen French Fries Production Line Chicken Slaughtering Machine

Chicken Slaughtering Machine Screw Potato Peeling Washing Machine

Screw Potato Peeling Washing Machine Cooked Meat Shredder Machine

Cooked Meat Shredder Machine Pizza Cone Equipment

Pizza Cone Equipment Model 330 Frequency Conversion High Speed Chopper

Model 330 Frequency Conversion High Speed Chopper