Best Meat Slicer Machine - Chinese Manufacturer, Factory, Supplier

When searching for the best meat slicer machine, precision and reliability are paramount. The ideal slicer should effortlessly cut through various types of meat, from delicate deli cuts to thicker, more robust portions, with uniform thickness and smooth edges. A high-quality best meat slicer machine not only enhances efficiency in the kitchen but also ensures consistent results, day after day.

Look for a slicer equipped with durable, rust-resistant blades made from stainless steel. These blades should maintain sharpness for longer periods, allowing for easy slicing without the need for constant re-sharpening. Additionally, a powerful motor is essential, as it provides the necessary torque to slice through different meat textures without difficulty or strain.

The best meat slicer machine also features adjustable settings, enabling you to control slice thickness according to your specific needs. Whether you're preparing paper-thin prosciutto or thicker cuts for steak sandwiches, versatility is key. For ease of use, opt for a model with ergonomic controls and easy-to-clean components, ensuring that maintenance is simple and quick.

Ultimately, the best meat slicer machine combines power, durability, and precision, making it an indispensable tool for home kitchens, delis, or butcher shops looking to elevate their meat preparation.

Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Electric Cooked Meat Slicer

Electric Cooked Meat Slicer Frozen Meat Slicer

Frozen Meat Slicer Smoked Furnace

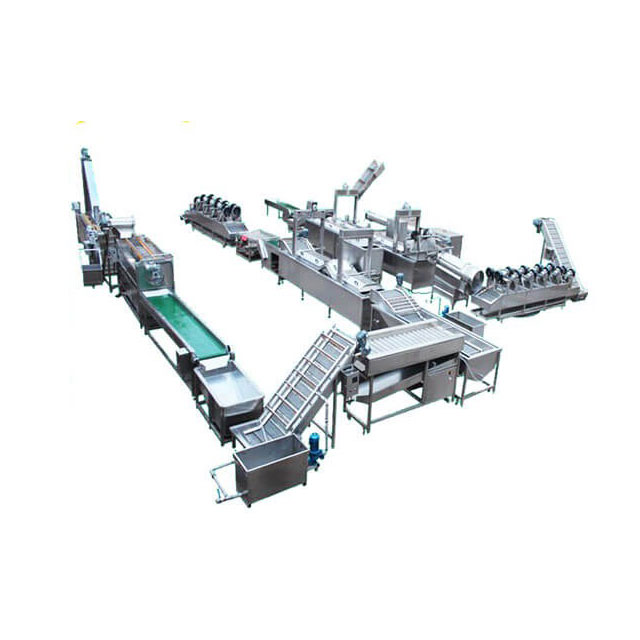

Smoked Furnace Frozen French Fries Production Line

Frozen French Fries Production Line Automatic Banana Chips Production Line

Automatic Banana Chips Production Line Tofu Production Line

Tofu Production Line Gas Shawarma Machine

Gas Shawarma Machine Automatic Belt Frying Machine

Automatic Belt Frying Machine Frozen Meat Grinder

Frozen Meat Grinder Frozen Meat Cube Cutting Machine

Frozen Meat Cube Cutting Machine