Best Chicken Shredder - Chinese Manufacturer, Factory, Supplier

For most people cooking at home, a manual chicken shredder tool is the top choice. These are affordable, easy to use, and widely available. My recommendation is the manual shredder from Walmart, which comes with a cleaning brush and a non-slip base.

- Why it’s great:

- It’s simple to operate—just place cooked chicken in the tool and twist or press to shred.

- The non-slip base keeps it steady, and the cleaning brush makes cleanup a breeze (it’s also dishwasher-safe).

- It’s budget-friendly and gets great reviews for shredding chicken, pork, or beef efficiently.

- Where to find it: Available at Walmart, both online and in stores.

If you shred chicken occasionally for tacos, salads, or meal prep, this tool will save you time compared to using forks. Some alternatives on Amazon or Target are similar, but the Walmart option stands out for its extras like the brush and solid user feedback.

Best for Large-Scale Use: Industrial Automatic Shredder

If you need to shred huge amounts of chicken—like for a restaurant or catering—consider an industrial automatic meat shredder. These machines are powerful and built for high volume.

- Top Options:

- Automatic Meat Shredder: Can process over 2,000 pounds of meat per hour with a consistent “hand-pulled” texture. Ideal for businesses.

- Shredders: Another commercial-grade choice for cooked chicken, pork, or beef.

- Why it’s great: Fast, consistent, and perfect for heavy-duty use.

- Downside: These are expensive and bulky, making them impractical for home kitchens.

Electric Options: Not Ideal for Chicken

You might wonder about electric shredders for home use. While there’s an electric option on Amazon, it’s not specifically designed for chicken. Reviews are mixed—some users mention battery issues or uneven shredding—so it’s not the best pick for this task.

What to Consider

- How often do you shred chicken? For occasional use, stick with a manual tool. For frequent, large batches, an industrial machine might make sense.

- Budget: Manual shredders are under $20, while industrial ones cost hundreds or thousands.

- Cleanup: Look for dishwasher-safe options or tools with cleaning aids.

- Versatility: Some manual shredders work for other meats or even veggies.

Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine Chicken Egg Peeling Machine

Chicken Egg Peeling Machine Chicken Feet Peeling Production Line

Chicken Feet Peeling Production Line Small Chicken Feet PeelingMachine

Small Chicken Feet PeelingMachine Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine Chicken Feet Cutting Machine

Chicken Feet Cutting Machine Meat Shredder Machine

Meat Shredder Machine Automatic Chicken Cutting Machine

Automatic Chicken Cutting Machine Cooked Meat Shredder Machine

Cooked Meat Shredder Machine 250kg/Hr Compound Potato Chips Frying Plant

250kg/Hr Compound Potato Chips Frying Plant Meat Pie Maker Machine

Meat Pie Maker Machine Small Scale Banana Chips Production Line

Small Scale Banana Chips Production Line Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment Pelmeni Making Machine

Pelmeni Making Machine Meat Stuffer Machine

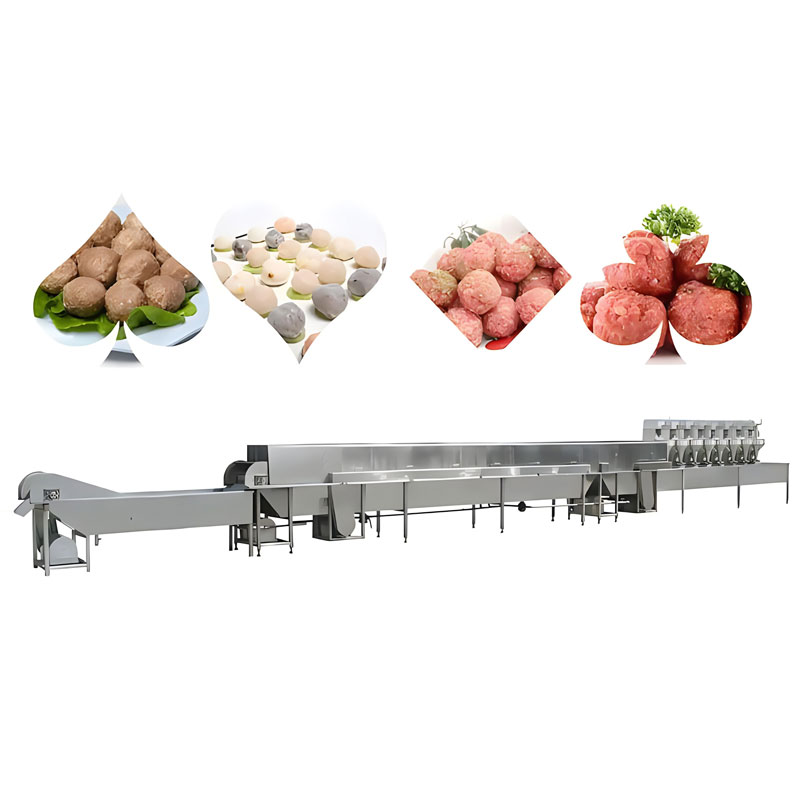

Meat Stuffer Machine Meatball Production Line

Meatball Production Line