Beef Bone Cutting Machine - Chinese Manufacturer, Factory, Supplier

In the intricate world of meat processing, where exactitude and celerity are paramount, the Beef Bone Cutting Machine stands as a titan of innovation. This robust apparatus, meticulously engineered to vanquish the unyielding density of bovine skeletal structures, has redefined the craft of butchery. No longer must artisans toil with rudimentary tools, battling fatigue and inconsistency. Instead, a new epoch dawns—one dominated by mechanized prowess, with the China Yuanlin Factory leading the charge in delivering unparalleled solutions to this demanding industry.

The Beef Bone Cutting Machine boasts formidable cutting puissance, driven by a motor often exceeding 2 horsepower. Its blades, forged from premium stainless steel, exhibit exceptional resilience, slicing through bone with surgical precision. Safety mechanisms—think blade guards and instantaneous shut-off systems—fortify its design, ensuring operators wield this power without peril. Such features elevate this machinery beyond mere butcher tools, positioning it as a cornerstone of industrial cutting machines.

Efficiency reigns supreme with this equipment. The Beef Bone Cutting Machine slashes processing times dramatically, transforming hours of arduous labor into mere minutes of seamless operation. This acceleration amplifies throughput, enabling meat processing plants to meet soaring demand with ease. Cost efficiencies follow suit, as reduced labor demands diminish overheads. Uniformity, too, is assured; each cut mirrors its predecessor, satisfying stringent quality benchmarks and delighting discerning clientele.

The China Yuanlin Factory emerges as a paragon of excellence in this domain. Renowned for its mastery in crafting food processing machinery, their offerings exude durability and ingenuity. Adjustable cutting velocities and bespoke blade arrays distinguish their Beef Bone Cutting Machine models, catering to enterprises of all scales—from quaint butcher shops to sprawling industrial complexes. Their expertise ensures that each unit integrates seamlessly into diverse workflows, optimizing operational synergy.

Consider the implications for your enterprise. A Beef Bone Cutting Machine is not merely equipment—it’s a strategic asset. Its adoption heralds enhanced productivity, fortified safety, and unwavering consistency. The China Yuanlin Factory stands ready to shepherd this transformation, providing not just machinery, but a legacy of precision engineering. Embrace this vanguard of meat processing equipment. Witness how it transmutes challenges into opportunities, propelling your operations into a future defined by excellence.

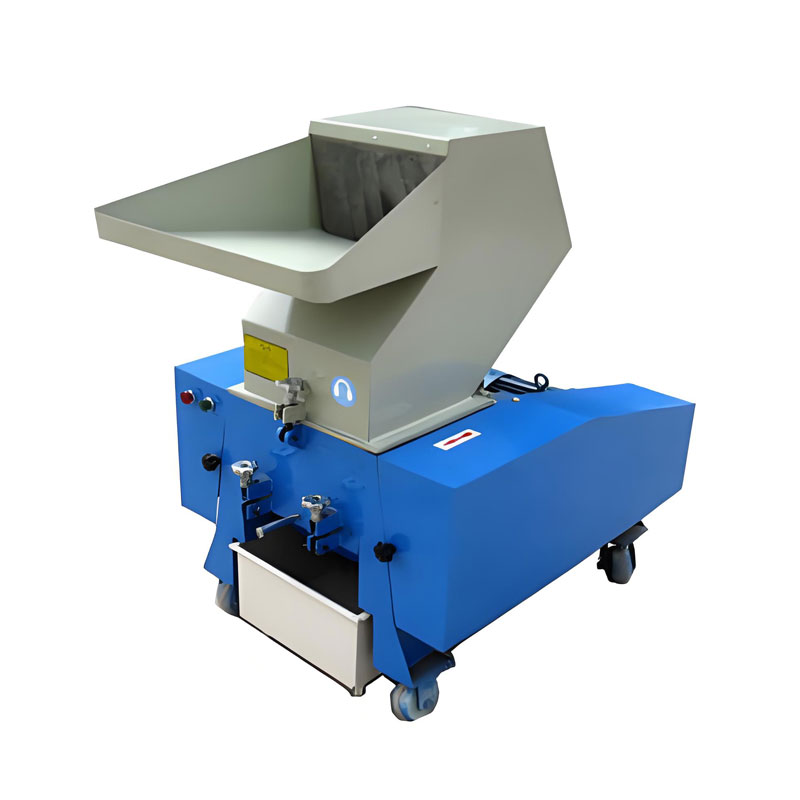

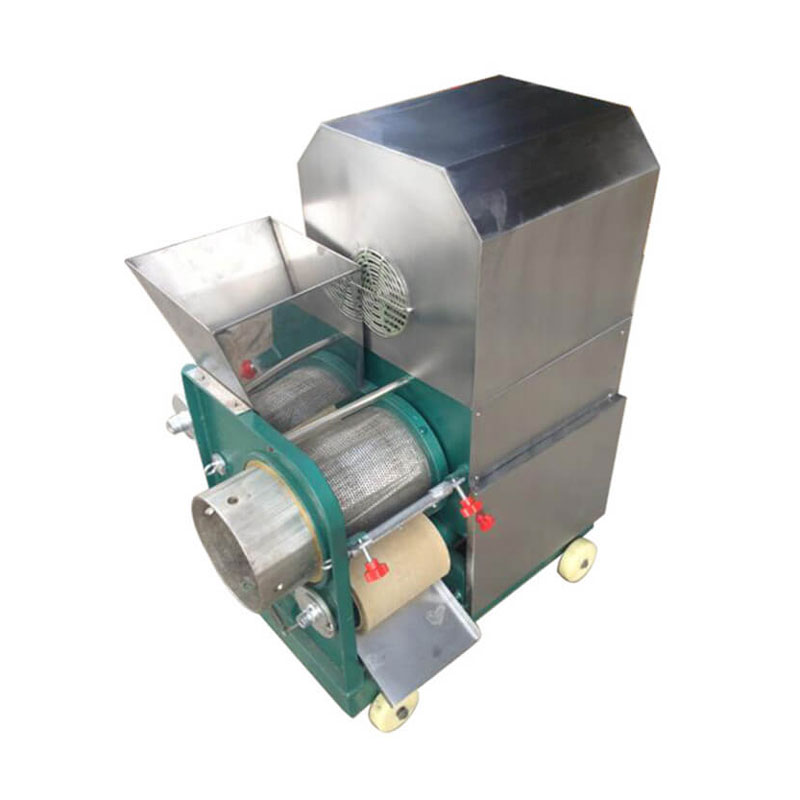

Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Fish Deboner Machine

Fish Deboner Machine Fish Cutting Machine

Fish Cutting Machine Chicken Feet Cutting Machine

Chicken Feet Cutting Machine Bone Crusher Machine

Bone Crusher Machine Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Automatic Chicken Cutting Machine

Automatic Chicken Cutting Machine Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine Frozen Meat Cube Cutting Machine

Frozen Meat Cube Cutting Machine Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine X-Type Cutting And Stringing Machine

X-Type Cutting And Stringing Machine YL-W-05 Commercial Water Purification Equipment

YL-W-05 Commercial Water Purification Equipment Pelmeni Making Machine

Pelmeni Making Machine Potato Washing&Peeling Machine

Potato Washing&Peeling Machine Frozen Meat Ribs Dicing Machine

Frozen Meat Ribs Dicing Machine Blast Freezer

Blast Freezer Fully Automatic Potato Chips Line

Fully Automatic Potato Chips Line Automatic Cooked Meat Slicing Machine

Automatic Cooked Meat Slicing Machine