Automatic Meat Slicer For Sale - Chinese Manufacturer, Factory, Supplier

Automatic meat slicers are indispensable tools for food processing,餐饮 businesses, and retail operations, enabling efficient, precise slicing of meats, cheeses, vegetables, and other ingredients. Their automation enhances speed, uniformity, and safety, making them essential for modern kitchens and industrial facilities. This guide provides an overview of features, selection criteria, and industry applications to help buyers choose the right machine.

Core Features and Benefits

Automatic meat slicers use motorized mechanisms to deliver continuous, consistent slicing, ideal for high-volume or repetitive tasks. Key advantages include:

- Efficiency :

- High-speed cutting : Some models achieve 50–200 slices per minute , reducing labor time.

- Adjustable slice thickness : Ranges from 0.5mm to 20mm , accommodating needs from ultra-thin prosciutto to thick steak slices.

- Safety :

- Anti-slip trays and clamps stabilize products during slicing.

- Emergency stop buttons and automatic power-off features comply with OSHA (Occupational Safety and Health Administration) standards.

- Versatility :

- Swappable blades for cutting meats, cheeses, vegetables, and even bread.

- Tilted knife racks handle irregularly shaped items like whole turkeys or smoked ribs.

Key Selection Criteria and Types

Automatic meat slicers are categorized by capacity and application:

| Type | Use Case | Core Features |

|---|---|---|

| Compact Countertop Slicers | Small restaurants, delis | Compact design, low power (0.5–1.5 HP), suitable for50–200kg/dayslicing. |

| Heavy-Duty Industrial Slicers | Factories, large chains | High power (2–5 HP), handles200–1,000kg/hour, corrosion-resistant stainless steel. |

| Fully Automatic Conveyor Slicers | Production lines, packaging plants | Continuous feed systems, integrates with conveyors forunmanned operation. |

Industry Applications

- Foodservice :

- Restaurants and hotels slice deli meats, cheeses, and cooked proteins for sandwiches or charcuterie platters.

- Bars and delis produce consistent slices for customer displays.

- Food Processing :

- Factories cut bacon, processed meats, or sausages for pre-packaged products.

- Handles frozen meat slicing (requires low-temperature blades ).

- Retail & Wholesale :

- Supermarkets slice meats and cheeses in-store to attract customers and extend shelf life.

- Wholesalers bulk-cut products to meet customer specifications.

Buying Considerations and Maintenance Tips

- Budget & Capacity :

- Compact models cost $500–$2,000 , while industrial units range $5,000–$20,000+ .

- Match capacity to demand: e.g., 2 HP motors for daily volumes exceeding 500kg.

- Safety & Compliance :

- Ensure compliance with FDA (US), CE (EU), or HACCP (Hazard Analysis and Critical Control Points) standards.

- Opt for non-slip bases and splash-proof designs for kitchen environments.

- Durability & Maintenance :

- Stainless steel construction resists corrosion for longevity.

- Clean blades and conveyors regularly to prevent cross-contamination.

- Store with blade guards to protect edges.

Top Brands and Models

- Leading Brands :

- Marel : Industrial-grade for meat processing plants.

- Cajun : Affordable, versatile units for small businesses.

- Waring Commercial : Multi-functional for home and commercial use.

- Hobart : Heavy-duty, durable equipment for high-volume operations.

- Popular Models :

- Cajun C-300 : Compact countertop model for 100kg/day slicing.

- Marel Flex 400 : Industrial conveyor system for production lines.

Conclusion

Automatic meat slicers are critical for boosting productivity, ensuring product consistency, and maintaining food safety in commercial settings. By aligning machine specifications with operational needs, businesses can reduce labor costs, enhance efficiency, and deliver high-quality sliced products to customers.

Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Electric Cooked Meat Slicer

Electric Cooked Meat Slicer Frozen Meat Slicer

Frozen Meat Slicer Gizzard Peeling Machine

Gizzard Peeling Machine Dough Roller Machine

Dough Roller Machine Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment Sausage Processing Line

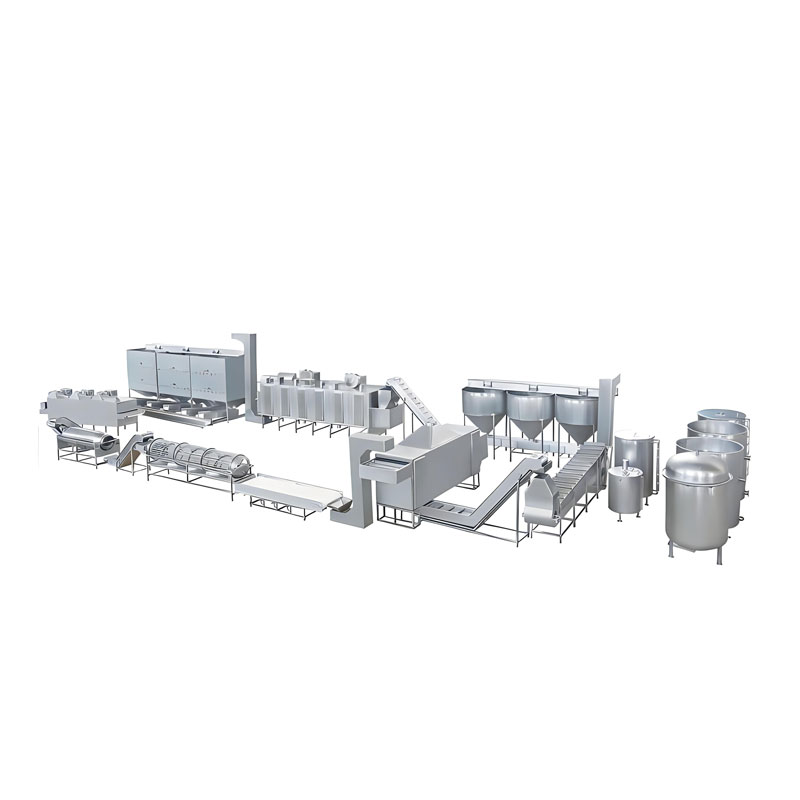

Sausage Processing Line Meat Smoking Machine

Meat Smoking Machine Kimchi Production Line

Kimchi Production Line Tomato Sauce Machine

Tomato Sauce Machine