Automatic Frozen Meat Chopping Machine - Chinese Manufacturer, Factory, Supplier

For food processing enterprises and culinary institutions striving for peak efficiency and uniformity, the preparation of frozen meats can often present a formidable logistical challenge. Traditional methods can be labor-intensive, time-consuming, and prone to inconsistencies in the final product. Enter the Automatic Frozen Meat Chopping Machine, a veritable paragon of modern food processing technology, poised to revolutionize how we handle deep-chilled comestibles. This sophisticated apparatus offers a streamlined solution, transforming rock-solid blocks of meat into precisely diced or sliced portions with remarkable alacrity and minimal human intervention.

The operational principle underpinning these machines is a marvel of engineering. Employing high-velocity reciprocating blades or rotating cutting assemblies crafted from robust alloys, they deftly shear through frozen protein, mitigating the risks associated with manual chopping, such as inconsistent sizing and potential injury. This automated process not only enhances workplace safety but also ensures a level of uniformity that is simply unattainable through manual techniques, a crucial factor for maintaining product quality and consistency in large-scale food production.

The benefits of integrating an Automatic Frozen Meat Chopping Machine into your workflow are manifold. Foremost among these is the significant reduction in labor costs and processing time. What previously required multiple personnel and considerable temporal investment can now be accomplished swiftly and efficiently by a single operator overseeing the machine's function. This enhanced throughput translates directly to increased productivity and a more streamlined operational cadence. Furthermore, the precision afforded by these machines minimizes waste, ensuring optimal utilization of raw materials and contributing to a more sustainable and economically sound operation.

When considering the acquisition of such a pivotal piece of equipment, the provenance and reputation of the manufacturer warrant meticulous scrutiny. Establishments such as the yuanlin Automatic Frozen Meat Chopping Machine factory have emerged as significant players in this specialized sector, offering a range of machines tailored to diverse processing needs and scales of operation. Scrutinizing factors such as build quality, blade material, safety features, and after-sales support is paramount in making an informed investment. The integration of an Automatic Frozen Meat Chopping Machine is not merely an acquisition of hardware; it is a strategic imperative for businesses seeking to optimize their frozen meat processing capabilities, enhance efficiency, and ultimately, elevate their operational efficacy. Embrace the future of food preparation and unlock unparalleled levels of productivity with this indispensable technology.

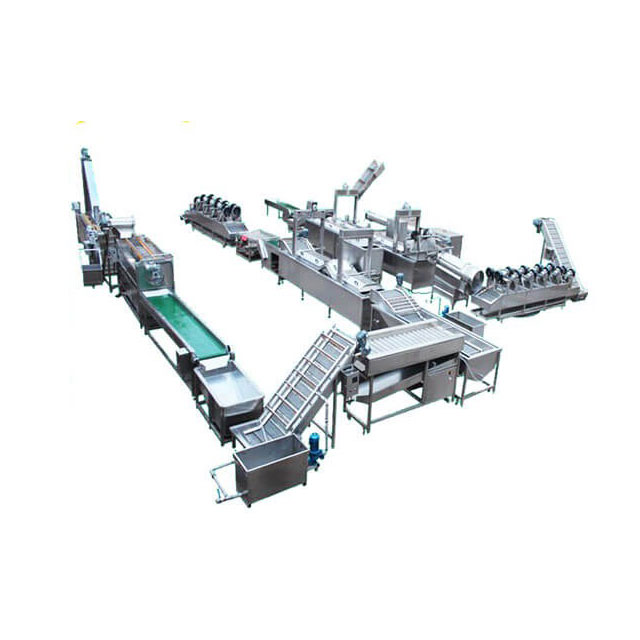

Frozen French Fries Production Line

Frozen French Fries Production Line Frozen Meat Ribs Dicing Machine

Frozen Meat Ribs Dicing Machine Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine Frozen Meat Cube Cutting Machine

Frozen Meat Cube Cutting Machine Industrial Frozen Meat Slicing Machine

Industrial Frozen Meat Slicing Machine Model 200 Frequency Conversion High Speed Chopper

Model 200 Frequency Conversion High Speed Chopper Frozen Meat Grinder

Frozen Meat Grinder Model 330 Frequency Conversion High Speed Chopper

Model 330 Frequency Conversion High Speed Chopper Frozen Meat Slicer

Frozen Meat Slicer Meat Tenderizer

Meat Tenderizer YL-W-04 Commercial Water Purification Equipment

YL-W-04 Commercial Water Purification Equipment Electric Cooked Meat Slicer

Electric Cooked Meat Slicer Smoked Furnace

Smoked Furnace Chicken Feet Peeling Production Line

Chicken Feet Peeling Production Line Automatic Sausage Peeling Machine

Automatic Sausage Peeling Machine