Tomato Paste Production mine Introduction

We offer complete, ready-to-operate tomato paste production lines built with cutting-edge technology and meticulous craftsmanship. Our lines boast a processing capacity of 2-10 tons of tomato paste per hour.

We provide comprehensive support, including on-site installation, commissioning, and training, tailored to your specific needs. Our tomato processing equipment is designed for efficiency and low energy consumption, making it a cost-effective solution for your business.

Advantages of Tomato Paste Processing line

1. Fruit washing machine features high cleanliness, saving energy and water, and stable and reliable performance.

2. Spraying devices, collection channels, and waste conveyors can be designed for the roller sorting machine.

3. The insulating layer can be designed for the tubular preheater and tubular sterilizer.

4. Various mesh size options for the fruit pulping machine in the tomato processing plant.

5. Concentrator features small size, simple structure, convenient operation, cleaning, and maintenance.

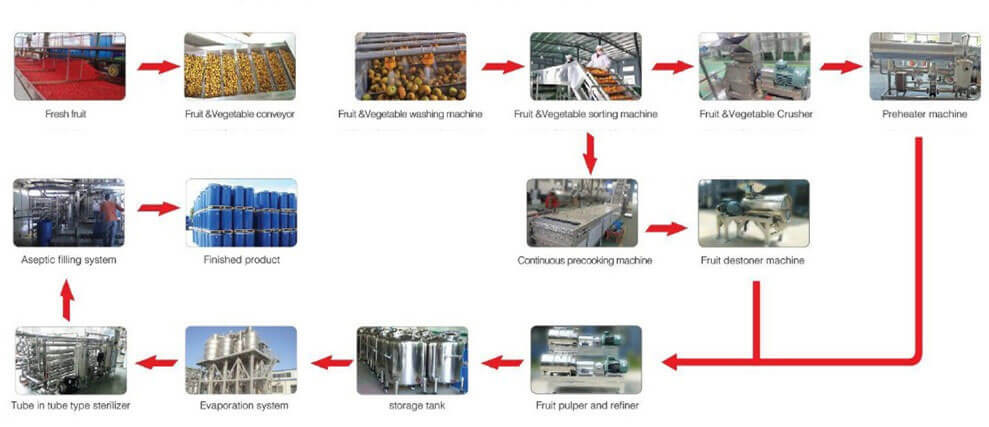

Working Flow of Tomato Paste Production Line

Fresh Tomato → Tomato Washing → Tomato Sorting → Breaking → Preheating → Tomato Pulping → Vacuum Concentration → Paste Sterilization → Finished Tomato Paste

Main Equipment in Tomato Paste Processing Plant

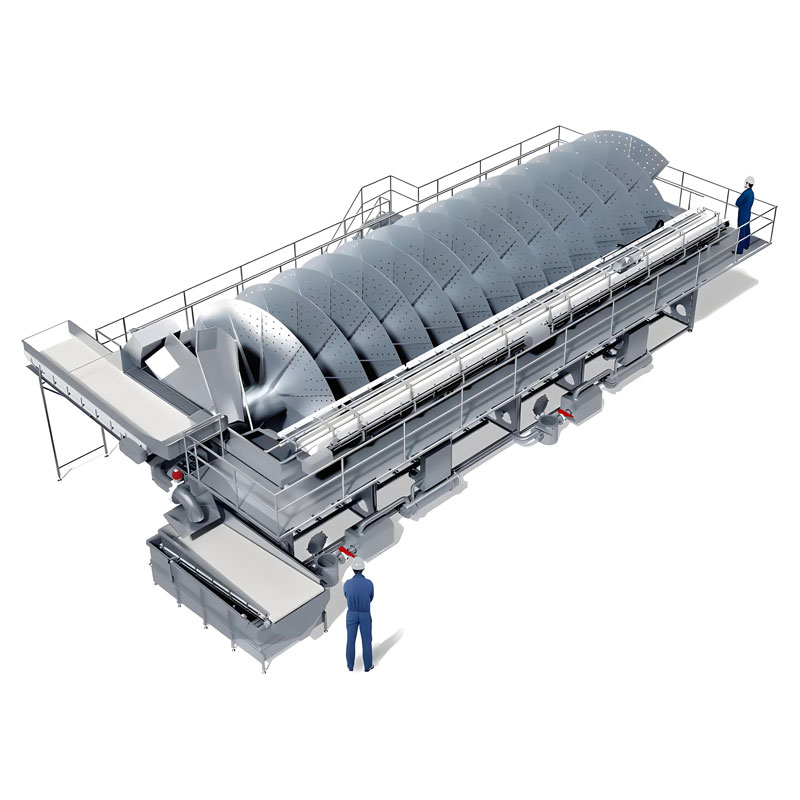

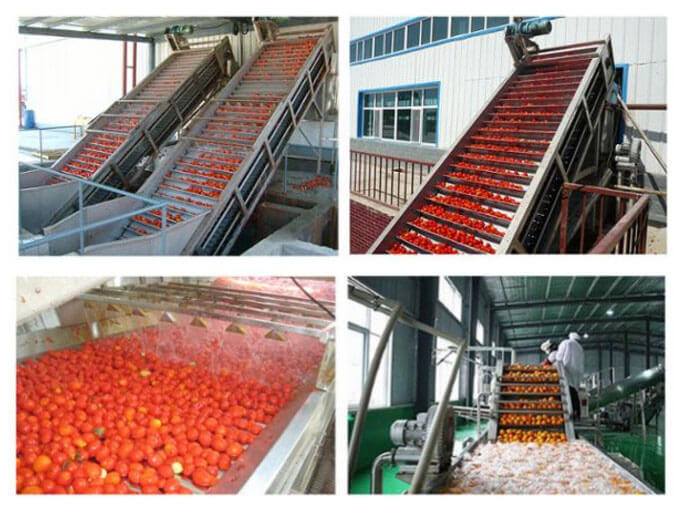

1. Surfing type washing machine

Tomatoes are washed with high-presure water in the frit washing machine, The scraper elevator conveys the cleaned tomatoesto the next procedure.

2. Roller sorting machine

Cleaned fruits enter into the machine from the feeding hopper, and rotate forward toward the outlet. Workers pick out theunqualified tomatoes to ensure the quality of the end product.

3.Broken Pump

Used for conveying and crushing tomatoes, and preparing for pre-heating and pulping.

4. Tubular Preheater

The tubular preheater increases the temperature of the pulp by steam heating to soften the pulp and deactivate the enzymes.

5. Single-channel Pulping Machine

The single-channel pulping machine is used for the automatic separation of pulp and residue from crushed and preheatedtomatoes, The material from the last procedure enters the machine through the feed inlet and spirals toward the outlet along thecvlinder, Bv centrifuga force, the matenlal is pulped, The pulp passes through the sieve and is sent to the next procedure, while theskin and seeds are discharged through the residue outlet, achieving the aim of automatic separation. The pulping speed can bechanged by changing the sieve and adjusting the lead angle of the scraper.

6. VacuumConcentrating Boiler

this equipment is used for vacuum concentration of tomato pulp under low temperatures, Steam is fed into the iacket at thelower part of the boiler, making the material under vacuum boil and evaporate. A blender in the boiler helps strengthen the flowof the material.

7.Tubular Sterilizer

Tubular sterilizer increases the temperature of the concentrate by steam heating, achieving the aim of sterilization.

Must-read blogs for bosses