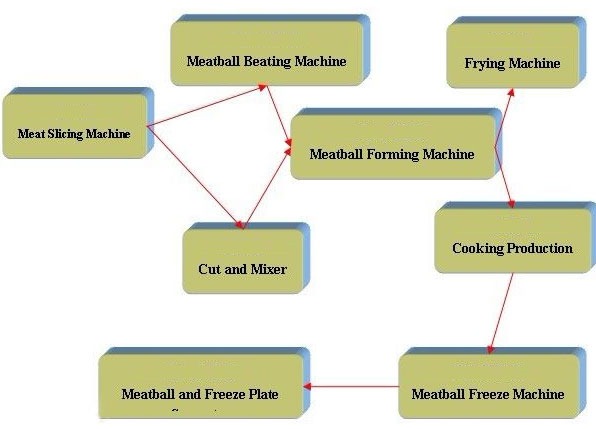

The meatball production line is composed of meatball forming machines, a meatball blanching machine, a bowl Chopper (Or Beater), a meat grinder, a frying machine or boiling machine, etc. The capacity of a single meatball forming machine is 100-120kg/h, several meatball forming machines will be used in a meatball production line. we can customize meatball production lines of different capacities according to your requirement.

A. The procedure of making fsh meatball

Raw fish→Fish scaling→fish skinning→Remove fish bones→Meat grinding/chopping Mix with seasonings→Form meatballs→BolingCooling→Packaging

Frozen fish meat→Slicing→Meat grinding/chopping→Mix with seasonings→Form meatball→Boling→Cooling→Packaging

B.The procedure of making beef/pork meatball

Beef/pork meat -Meat chopping→Meat grinding→mix with seasonings→Meatball forming→Boling→Cooling→Packaging

Meatball Production Line Application

Our meatball production line is suitable for producing various meatballs, like pork balls, beef balls,fish balls,vegetable balls, and so on. Meatbalsproduced by our meatball production line are of perfect and consistent shapes, have good taste, and are uniform in size. The production line keeps theproduct structure intact and has a high production capacity.

Advantages of Our Meatball Production Line

The whole line is made of SUS 304 stainless steel and NSF materials in line with the food’s healthy standards, and it is durable and healthy.

The conveyor is driven by a chain.

Sectional type automatic temperature control.

Adjustable boiling speed and water speed.

High safety and easy operation.

The production line can produce various sizes and kinds of meatballs.

Meatballs produced by our Meat Production Line are with good taste, smooth surface, and high flexibility.

The Main Working Principle of Automatic Meatball Production Line

The water in the meatball molding groove and cooking groove are heated by the steam pipeline, the water temperature is controlled by the high-temperature and high-pressure valve, and giving the temperature of water in the molding groove is around 75-degree centigrade, and the temperature of water in the cooking groove about 90-degree centigrade. The water circulation system makes the water in the molding groove into the flowing water and the meatballs flow with the flowing water towards the end of the molding groove. The flowing procedure is controlled by the control valve to realize the ideal meatball molding effect.

After molding, meatballs are cooked in the cooking groove, and then the cooked meatballs are moved to the end of the cooking groove at a constant speed by the rotary switch-plate. The cooking time for different kinds of meatballs is different, it can be controlled by adjusting the rotary speed of the switch plate.

The cooked meatballs are conveyed into the cooling groove to cool quickly. The water in the cooling groove is open; while the cold water flows in, the warm water flows out, in order to keep the water temperature around 25-degree centigrade. The cooled meatball can be sent to the quick-frozen workshop to freeze. Then the frozen meatballs are packaged.

Must-read blogs for bosses