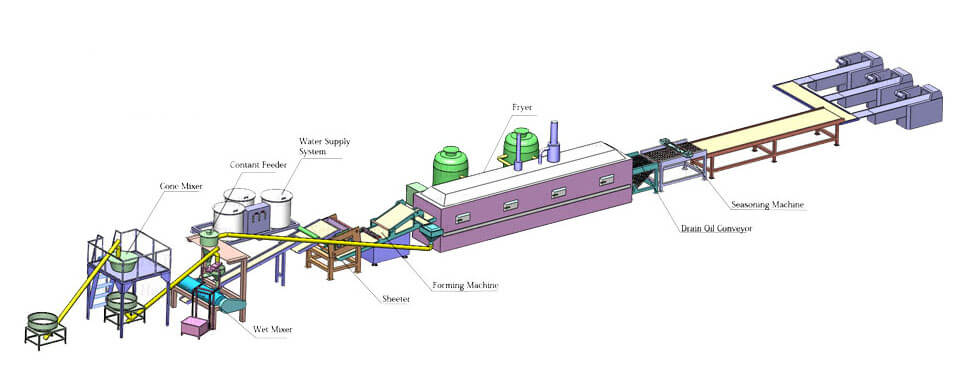

Introduction of Automatic Compound Potato Chips Line

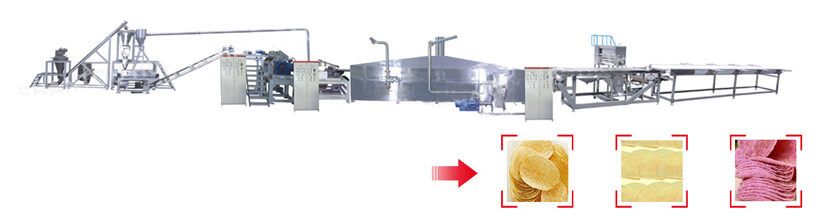

The automatic compound potato chips production line utilizes potato powder or potato flour as its primary raw material. One of its key advantages lies in its efficient utilization of raw materials, facilitated by a recycling system that reuses residual dough. The resulting compound potato chips boast uniform shapes and a rich aroma, suitable for packaging in paper tubes or small bags. Currently, the most popular brands of compound potato chips include Pringles and Lay's.

Advantages of Compound Potato Chips Frying Plant

1. Full automatic PLC control system, all of the control elements adopt internationally wel-known brands, high precision, andreliability.

2. Labor saving. The whole line is highly automatic, only 8 - 10 workers are needed to operate it.

3. Provide whole factory planning, personnel planning, product material analysis, and technological formulation.

4. Many different flavors could be made by spraying diferent flavored powder, such as tomato flavor, seaweed flavor, spicy flavorand so on.

5. The standard capacity of this automatic compound potato chips line is 250 kg/hr, but we can customize the completeproduction line based on your needs.

Main Processing Steps Of Automatic Compound Potato Chips Line

Mixing→Lifting→Dosing→Mixer→Lifting And Spreading→Sheeting→Forming→Oil Frying→Oil Filtering→Spraying Season→Cooling And Collecting→Packaging

Main Machines Details of 250kg/hr Compound Potato Chips Plant

1. Dry Mixing Machine

The dry mixing machine is one of the important equipment in the automatic compound potato chips plant, it is used to mix the raw material.

2. Wet Mixer

Wet mixer is one of the important equipment of the complex potato chips production line. it can be used to mix the potato powder with water and to be ready for sheeting.

3. Stirring mixer

A stirring mixer is for mixing raw materials by stirring

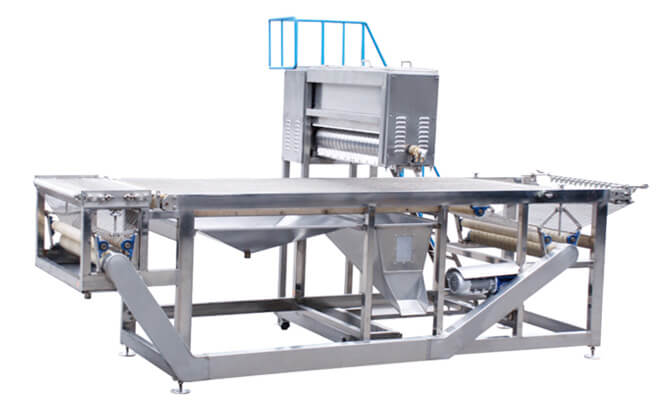

4. Sheeting Machine

The sheeting machine can spread the wet potato powder into the required thickness dough sheet. Advanced technology of Twin rollers desian for qood effect dough sheet.

5. Forming machine

Forming machine can be used to form the shape of the chips.

6.Disintegrator system

A disintegrator system is used to recycle the leftover material.

7. Frying machine

The fryer can be used to fry the chips and make the compound chips a fix shape

8. Flavoring system with conveyor

A flavoring system with a conveyor can be used to flavor the chips with diferent flavoring. it is a good effect seasoning machine for spraying different flavoring powder.

9. Food Conveyor

The conveyor is for conveying the finished potato chips to the packing line. With a PLC system inside, the operator can choose automatic control or manual control mode.

Must-read blogs for bosses