Which Types Of Meat Processing Equipment Are The Most Automated

In today's fiercely competitive meat processing industry, the introduction of automation technology not only enhances production efficiency but also ensures product consistency and quality. As technology advances, an increasing number of meat processing equipment have achieved high levels of automation. This article will delve into the types of meat processing equipment with the highest automation levels and how they are transforming the landscape of meat processing.

1. Automated Cutting Equipment

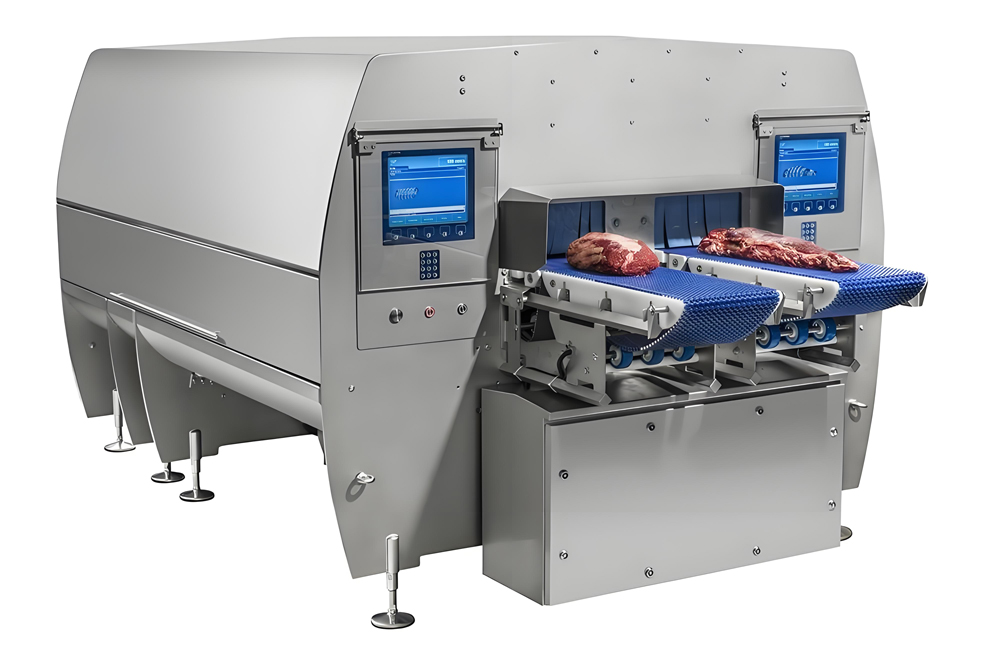

a. CNC Cutting Machines

CNC (Computer Numerical Control) cutting machines are crucial in modern meat processing, capable of precisely slicing meat according to preset parameters. The advantages include:

- Precision: CNC systems ensure each cut meets standards, reducing waste.

- Consistency: Uniformity in thickness and shape enhances product quality.

Efficiency: Compared to manual cutting, CNC machines operate faster, significantly boosting production efficiency.

b. Laser Cutting Machines

Laser cutting machines utilize high-energy laser beams for cutting, offering greater flexibility and precision. They are particularly effective for handling specially shaped meat products.

2. Automated Packaging Equipment

a. Vacuum Packaging Machines

Vacuum packaging machines automate the packaging process, effectively extending the shelf life of meat products. Key features include:

- Automated Operation: The entire process, from material handling to sealing, is automated, minimizing human intervention.

- Seal Integrity: Vacuum sealing technology effectively prevents oxygen ingress, prolonging shelf life.

b. Labeling Machines

Modern labeling machines are often integrated with automated packaging machines to achieve high-speed labeling, ensuring accurate product information.

3. Automated Cleaning Systems

In meat processing, hygiene is critical. Automated cleaning systems ensure efficient cleaning of equipment.

a. Automated Cleaning Machines

These machines combine high-pressure water jets with cleaning agents to complete the cleaning of equipment in a short time. Advantages include:

- Water Conservation: More water-efficient than traditional cleaning methods.

- High Efficiency: Reduces cleaning time, allowing for quick recovery of production lines.

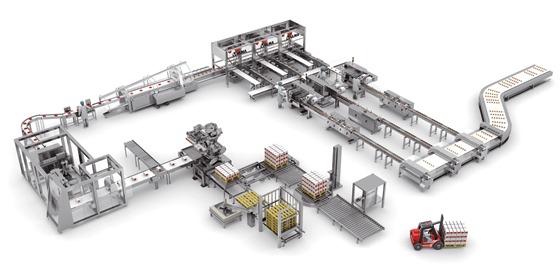

4. Automated Loading and Unloading Systems

a. Robotic Loading Systems

Utilizing industrial robots for loading and unloading not only increases operational efficiency but also reduces reliance on human labor. Advantages include:

- Flexibility: Robots can adapt to various product types and packaging.

- Safety: Minimizes the risk of human error and accidents.

b. Automated Conveyor Systems

Automated conveyor belts efficiently transport raw materials and finished products between different processing stages, reducing wait times.

5. Data Analysis and Monitoring Systems

In the most automated meat processing equipment, data monitoring and analysis systems play a vital role.

a. Production Monitoring Systems

Through sensors and monitoring software, real-time tracking of every production stage is possible. This enhances efficiency and allows for timely problem detection and adjustments.

b. Predictive Maintenance Systems

Leveraging big data and machine learning technologies, predictive maintenance systems forecast equipment maintenance needs, reducing downtime due to failures.

Conclusion

The introduction of automated equipment in the meat processing industry significantly enhances production efficiency and product quality. By utilizing CNC cutting machines, automated packaging equipment, cleaning systems, loading and unloading systems, and data analysis systems, companies can stand out in a competitive market. With continuous technological advancements, future meat processing equipment will become even more intelligent, creating new opportunities for industry growth.

Must-Read Blogs For Chain Restaurants Owner

Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine

Ready to Get Started?