What Are The Machines Used For Meat Production?

From farm to fork, the journey of meat production is a complex one, involving a fascinating array of machinery designed to ensure efficiency, safety, and quality. While the image of a traditional butcher shop might come to mind, modern meat production relies heavily on advanced technology to meet the demands of a growing global population.

This article delves into the world of meat processing machinery, exploring the key players involved in each stage of the process, from slaughtering and deboning to packaging and labeling.

1. Slaughterhouse Equipment:

The initial stage of meat production involves the humane and efficient slaughter of animals. This requires specialized equipment designed to minimize stress and ensure animal welfare.

Stunning Equipment: This equipment renders animals unconscious before slaughter, using methods like electrical stunning, captive bolt pistols, or gas stunning.

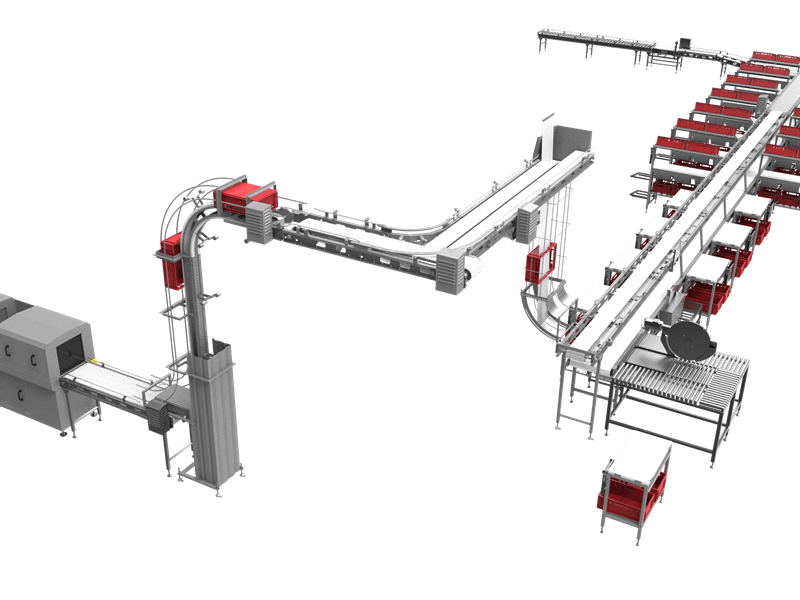

Slaughter Lines: These automated conveyor systems move animals through the slaughter process in a controlled and efficient manner.

Hide/Skinning Machines: These machines remove the hide or skin from the carcass, often using a combination of mechanical blades and water jets.

Evisceration Equipment: This equipment removes the internal organs from the carcass, ensuring proper hygiene and sanitation.

2. Deboning and Cutting Equipment:

Once the carcass is slaughtered and cleaned, it undergoes deboning and cutting to produce various cuts of meat.

Band Saws: These saws are used to cut through bones and large sections of meat, producing primal cuts.

Bone Saws: These saws are specifically designed for cutting through bones, allowing for precise removal of bones from meat.

Trimming Machines: These machines use rotating blades to trim excess fat and connective tissue from meat, improving its appearance and quality.

Portioning Machines: These machines automatically cut meat into uniform portions, such as steaks, chops, or ground meat.

3. Further Processing Equipment:

Many meat products undergo further processing to enhance flavor, texture, or shelf life.

Grinders: These machines grind meat into various textures, from coarse ground beef to fine sausage meat.

Mixers: These machines blend ground meat with seasonings, spices, and other ingredients to create sausages, patties, and other processed meats.

Stuffers: These machines fill casings with ground meat mixtures to produce sausages, frankfurters, and other stuffed products.

Smoking Equipment: This equipment uses smoke to impart flavor and preserve meat products, such as bacon, ham, and smoked sausages.

4. Packaging and Labeling Equipment:

The final stage of meat production involves packaging and labeling the finished products for distribution and sale.

Vacuum Packaging Machines: These machines remove air from packaging to extend shelf life and prevent spoilage.

Modified Atmosphere Packaging (MAP) Machines: These machines replace air in packaging with a specific gas mixture to further enhance shelf life and preserve freshness.

Labeling Machines: These machines apply labels to packages, providing information about the product, such as ingredients, nutritional content, and expiration date.

5. Sanitation and Hygiene Equipment:

Maintaining strict hygiene standards is crucial in meat processing to prevent contamination and ensure food safety.

Washdown Systems: These systems use high-pressure water jets to clean equipment and surfaces, removing bacteria and other contaminants.

Sanitizing Equipment: This equipment uses chemical sanitizers to kill bacteria and other microorganisms on surfaces and equipment.

Air Filtration Systems: These systems remove airborne particles and contaminants from the processing environment, reducing the risk of contamination.

Benefits of Modern Meat Processing Machinery:

The use of advanced machinery in meat production offers numerous benefits:

Increased Efficiency: Automation and mechanization significantly increase processing speed and output, meeting the demands of a growing population.

Improved Safety: Specialized equipment minimizes the risk of injury to workers and ensures the humane treatment of animals.

Enhanced Quality: Precise cutting, trimming, and processing techniques result in higher quality meat products with consistent texture and flavor.

Extended Shelf Life: Vacuum packaging and MAP technologies extend the shelf life of meat products, reducing waste and spoilage.

Stricter Hygiene Standards: Automated cleaning and sanitizing systems ensure a hygienic processing environment, minimizing the risk of contamination.

Conclusion:

The machinery used in modern meat production plays a vital role in ensuring a safe, efficient, and sustainable food supply. From slaughtering and deboning to packaging and labeling, each stage of the process relies on specialized equipment designed to meet the highest standards of quality, safety, and hygiene. As technology continues to advance, we can expect to see even more innovative machinery emerge, further improving the efficiency and sustainability of meat production.

Must-Read Blogs For Chain Restaurants Owner

Sausage Stuffer Machine

Sausage Stuffer Machine Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine Poultry Feather Removal Machine

Poultry Feather Removal Machine

Ready to Get Started?