The Importance of Frozen Meat Dicing Machines in Modern Processing

In the realm of modern food production, frozen meat dicing machines are nothing short of revolutionary. They redefine efficiency and precision in commercial kitchens and industrial factories alike. Every slice, every dice is executed with unwavering consistency, transforming raw materials into culinary masterpieces and premium products.

How These Machines Revolutionize Meat Preparation in Commercial Kitchens and Factories

Frozen meat dicing machines usher in an era of unparalleled productivity. They enable rapid, hygienic processing while preserving the structural integrity and quality of meat. In bustling commercial kitchens and high-capacity factories, these machines eliminate laborious manual dicing, reducing errors and accelerating turnaround times. Their integration fosters an ecosystem where innovation and safety go hand in hand, ensuring that every product meets the highest standards.

What Exactly Is a Frozen Meat Dicing Machine?

A frozen meat dicing machine is a sophisticated apparatus engineered for the precise and efficient cutting of pre-frozen meat blocks. It amalgamates cutting-edge technology with robust construction to deliver consistent, uniform dicing. By operating at sub-zero temperatures, it preserves freshness and quality while mitigating bacterial growth. The result is an immaculate product that stands out in both visual appeal and texture.

A Technical Breakdown of Its Design and Functionality

These machines boast an intricate design that marries advanced metallurgy with precision engineering. At their core lies a high-torque motor coupled with meticulously aligned blade arrays. The system is calibrated to perform rapid, consistent cuts through frozen substrates. Adjustable feed rates, modular components, and high-performance control systems converge to create a device that is both versatile and reliable. Short pulses of energy combine with sustained power to ensure every cut is as exact as the last.

The Role of Manufacturers in the Supply Chain

Manufacturers are the unsung heroes behind these marvels of machinery. They are the architects of innovation and quality, setting the benchmark for performance in the frozen meat processing sector. Their expertise drives advancements that ripple throughout the supply chain, ultimately elevating standards across the board.

How Leading Brands Shape Innovation and Quality Standards

Pioneering manufacturers infuse their products with ingenuity and relentless precision. They establish rigorous quality controls and spearhead technological breakthroughs that redefine operational efficiency. These brands are synonymous with reliability, ensuring that every machine meets a myriad of safety and performance certifications. Their contributions create a legacy of excellence, ensuring that even the most demanding processing environments are catered to with finesse.

Key Factors to Consider When Choosing a Manufacturer

When selecting a manufacturer, it is crucial to look beyond mere price tags. Durability, safety, and the potential for customization must guide your decision-making process.

Beyond Price: Prioritizing Durability, Safety, and Customization

Investing in a frozen meat dicing machine is a strategic decision that demands attention to detail. A robust machine built for longevity ensures minimal downtime and enhanced productivity. Safety features such as emergency shut-offs and secure blade enclosures are non-negotiable. Moreover, customization options—ranging from adjustable feed rates to modular designs—allow the equipment to be tailored specifically to your operational demands.

Quality Standards: Certifications That Matter

In an industry where food safety is paramount, adherence to established quality standards is critical.

ISO, HACCP, and FDA Compliance for Food Safety

Certifications like ISO, HACCP, and FDA compliance serve as the bedrock of trust in meat processing equipment. These credentials guarantee that the machine meets stringent safety protocols and quality benchmarks. The assurance of regulatory compliance not only protects consumer health but also enhances the reputation of your business in a competitive market.

Customization Options: Tailoring Machines to Your Workflow

Modern processing demands flexibility. Customization options empower businesses to optimize machinery to suit their specific needs.

Modular Designs and Adjustable Settings for Versatility

Modular designs and adjustable settings allow for an adaptable approach to processing. Whether it’s tweaking blade sizes, modifying feed rates, or configuring output settings, customization ensures that the machine evolves in tandem with your workflow. This adaptability fosters a seamless integration into existing operations, guaranteeing that efficiency and quality are never compromised.

Customer Support: The Hidden Advantage of Reliable Brands

Exceptional customer support can be a game-changer in maintaining operational continuity.

24/7 Technical Assistance and Warranty Coverage

Reliable brands understand that prompt support is indispensable. Round-the-clock technical assistance, comprehensive warranty coverage, and proactive after-sales service ensure that any hiccup is swiftly addressed. This hidden advantage not only mitigates potential downtime but also reinforces the long-term value of your investment.

Top Manufacturers Leading the Industry

The global market is replete with manufacturers who are pushing the boundaries of what is possible in meat dicing technology.

Global Giants and Hidden Gems Shaping the Market

From global titans with decades of experience to emerging brands boasting innovative designs, the market offers a rich tapestry of options. Each manufacturer brings a unique blend of expertise, innovation, and market insight, catering to diverse operational needs.

Industry Titans: Names You Can Trust

Established industry titans have a proven track record of delivering machines that thrive under high-volume conditions. Their equipment is synonymous with durability, precision, and efficiency, making them the preferred choice in many large-scale processing environments.

Emerging Brands: Cutting-Edge Technology at Competitive Prices

New entrants in the market are challenging traditional paradigms with cutting-edge technology and competitive pricing. These emerging brands offer contemporary solutions that do not sacrifice performance for cost, presenting a compelling case for those looking to modernize their processing capabilities.

Regional Leaders: Finding the Best in Your Area

In many regions, local manufacturers excel by offering tailored solutions and rapid support. Their proximity often translates into a better understanding of local market demands and regulatory landscapes, ensuring that the equipment meets precise regional specifications.

China Yuanlin Factory: A Case Study in Excellence

At the forefront of innovation, the China Yuanlin Factory exemplifies excellence in frozen meat processing equipment. With a focus on proprietary blade technology and energy efficiency, they have carved a niche for themselves in the global market.

Why This Manufacturer Stands Out in the Frozen Meat Processing Sector

Their unwavering commitment to quality, coupled with an expansive export network, positions them as a leader in the industry. Their machines are renowned for consistent performance, bolstered by advanced features and a focus on user-centric design.

Proprietary Blade Technology for Consistent Cuts

The blade is the heart of every meat dicing machine, and proprietary technology in this area is paramount.

Diamond-Coated Edges and Anti-Stick Surfaces

Advanced blade designs incorporate diamond-coated edges and anti-stick surfaces, ensuring clean, precise cuts every time. These innovations reduce wear and tear, maintain sharpness, and prevent product buildup, thereby extending the operational lifespan of the machine.

Energy-Efficient Models for Sustainable Operations

In today’s eco-conscious market, energy efficiency is more than a feature—it is a necessity.

Global Customer Base and Export Expertise

Energy-efficient models reduce operational costs and environmental impact simultaneously. Manufacturers with a global customer base and export expertise are adept at integrating sustainable features without sacrificing performance, ensuring that efficiency and responsibility coexist seamlessly.

Price Range and Cost Considerations

Balancing performance with cost is a delicate dance, one that requires careful analysis and strategic budgeting.

Budgeting for Performance Without Overpaying

The spectrum of frozen meat dicing machines ranges from entry-level to high-end models. It is crucial to budget wisely, ensuring that you secure a machine that delivers robust performance without undue financial strain.

Entry-Level Machines: Ideal for Small-Scale Operations

These machines offer a cost-effective solution for smaller operations, providing essential functionality without unnecessary frills. They are perfect for businesses just embarking on their journey toward automation.

Mid-Range Options: Balancing Features and Affordability

Mid-range models strike a harmonious balance between innovation and cost. They deliver advanced features at a moderate price point, making them suitable for businesses ready to scale up operations while maintaining fiscal prudence.

High-End Models: Investing in Precision and Longevity

For enterprises with high-volume demands, high-end models represent a sound investment. They are engineered for longevity, precision, and consistent performance, ensuring that every cut is executed with meticulous accuracy.

Hidden Costs: Maintenance, Training, and Spare Parts

It is imperative to account for hidden costs such as maintenance, training, and spare parts. A comprehensive evaluation of total ownership expenses can prevent unforeseen financial pitfalls down the line.

Evaluating Manufacturer Reputation

The reputation of a manufacturer is often a reliable indicator of product quality and service excellence.

How to Spot Trusted Brands Amidst Competitors

Thorough research and industry insight can help distinguish reputable manufacturers from the rest. Look for a consistent track record, robust customer support, and an unwavering commitment to innovation.

Customer Reviews and Testimonials

Real-world feedback from commercial users provides a candid glimpse into the performance and reliability of the equipment. These testimonials can offer invaluable insights that go beyond marketing rhetoric.

Industry Awards and Recognition

Accolades and industry awards further substantiate the quality and reliability of a manufacturer’s offerings. Longevity in the market and a history of accolades are hallmarks of trust and excellence.

Customization Options: Tailoring to Your Needs

The ability to tailor machinery to your specific requirements can dramatically enhance operational efficiency.

Adjusting Blade Sizes, Feed Rates, and Output Settings

Flexibility is achieved through adjustable blade sizes, variable feed rates, and customizable output settings. These features allow the machine to be finely tuned to meet your exact processing needs.

Modular Design for Future Upgrades

A modular design not only facilitates immediate customization but also paves the way for future upgrades. This scalability ensures that the equipment remains relevant as your business evolves.

Integration with Existing Equipment

Seamless integration with current production lines minimizes disruptions and maximizes efficiency. Compatibility with existing equipment is a critical factor in ensuring a smooth transition to new technology.

Maintenance and Long-Term Costs

Sustaining the performance of a frozen meat dicing machine requires a proactive approach to maintenance and cost management.

Extending the Lifespan of Your Frozen Meat Dicing Machine

Regular maintenance is the linchpin of long-term operational success. A well-maintained machine consistently delivers top-notch performance, reducing the likelihood of unexpected breakdowns.

Preventive Maintenance Schedules

Establishing a rigorous preventive maintenance schedule is essential. Routine inspections, lubrication, and adjustments can forestall costly repairs and extend the machine’s service life.

Blade Replacement Strategies

Since blades are subject to wear, a strategic plan for timely replacement is crucial. Ensuring that sharp, high-quality blades are always on hand can significantly enhance efficiency and output quality.

Energy Consumption and Operational Costs

Monitoring energy consumption and other operational costs helps in making informed decisions about upgrades and efficiency improvements. Reducing these expenses can lead to substantial savings over time.

Case Studies: Success Stories from Major Brands

Real-world examples underscore the transformative impact of choosing the right frozen meat dicing machine.

Businesses That Boosted Efficiency with the Right Machine

Numerous enterprises have experienced a dramatic increase in efficiency by integrating state-of-the-art dicing machines. Their success stories serve as persuasive proof of the tangible benefits that come with a well-chosen machine.

A Restaurant Chain’s Transition to Frozen Meat Precision

One prominent restaurant chain revamped its operations by adopting precision dicing technology, resulting in enhanced consistency and reduced preparation time. This transition not only improved product quality but also streamlined service delivery.

A Meatpacking Plant’s Production Overhaul

A leading meatpacking plant witnessed a significant production overhaul after installing high-performance dicing machines. The optimized workflow led to increased throughput, reduced waste, and elevated product quality.

Future Trends Shaping the Market

The future of frozen meat dicing machines is brimming with technological innovation and sustainability.

Innovations in Automation and Smart Technology

The convergence of automation and smart technology is set to redefine meat processing. Cutting-edge systems are being designed to optimize performance through real-time monitoring and adaptive controls.

AI-Driven Dicing for Zero Waste

Artificial intelligence is paving the way for zero-waste processing. Smart algorithms can dynamically adjust settings to ensure that every cut is optimized for minimal waste and maximum yield.

IoT Integration for Remote Monitoring

Internet of Things (IoT) integration allows for remote monitoring and diagnostics. This connectivity enhances operational efficiency and enables proactive maintenance, reducing downtime and unforeseen expenses.

How to Negotiate the Best Deal

Acquiring a frozen meat dicing machine is a strategic investment that demands savvy negotiation.

Strategies for Securing Discounts and Financing Options

Employ a methodical approach to negotiation. Explore various financing options and discounts to ensure that your investment is both sound and cost-effective.

Leasing vs. Buying: Which Saves More Money?

Weigh the pros and cons of leasing versus buying. Leasing might offer lower upfront costs, while purchasing outright can yield long-term savings and full control over the asset.

Bulk Purchase Incentives

Consider bulk purchase incentives if you require multiple machines. This strategy can unlock significant discounts, enhancing overall cost efficiency.

Hidden Costs to Avoid

Remain vigilant about hidden costs. Shipping, installation fees, training, and certification requirements can quickly add up, so it is essential to factor these into your negotiations.

Common Pitfalls That Increase Total Ownership Expenses

Be wary of unforeseen expenses that can inflate total ownership costs. A comprehensive review of all associated fees and potential upgrades will help you avoid costly mistakes.

Shipping and Installation Fees

Training and Certification Requirements

These aspects are often overlooked but can substantially impact the final cost. Ensure that these services are clearly outlined and, if possible, included in your warranty or service contract.

Safety and Compliance Standards

Ensuring that your machine meets stringent safety and compliance standards is vital for both operational integrity and regulatory adherence.

Ensuring Your Machine Meets Regulatory Requirements

Compliance with OSHA and FDA guidelines is non-negotiable. The machine must adhere to strict safety protocols to protect both the workforce and the product.

OSHA and FDA Guidelines for Meat Processing Equipment

A rigorous adherence to OSHA and FDA standards ensures that your operations are safe and legally compliant. This adherence not only safeguards your employees but also bolsters your brand’s reputation.

Anti-Microbial Coatings and Sanitation Protocols

Advanced anti-microbial coatings and robust sanitation protocols are essential features. They prevent contamination and maintain the highest standards of hygiene in processing environments.

Energy Efficiency and Sustainability

Sustainability is no longer an option—it is a cornerstone of modern industrial practices.

Eco-Friendly Features That Reduce Your Carbon Footprint

Energy efficiency and eco-friendly components, such as low-power motors and recyclable materials, reduce both environmental impact and operational costs.

Low-Power Motors and Recyclable Components

Water-Saving Dicing Systems

These features exemplify the commitment to sustainability while delivering uncompromised performance.

Scalability: Growing with Your Business

Invest in a machine that evolves with your business. Scalability is key to ensuring long-term success and operational flexibility.

Choosing a Machine That Grows as Your Demand Increases

A scalable system adapts to fluctuating production demands. Adjustable capacity settings and expandable modules ensure that the machine remains efficient as your business scales.

Adjustable Capacity Settings

Expandable Systems for Future Needs

These features allow for seamless upgrades and integration, ensuring that your processing line remains at the cutting edge.

Global vs. Local Manufacturers: Which Is Better?

Choosing between global and local manufacturers involves a delicate balance of cost, shipping, and support.

Weighing Cost, Shipping, and Support

Global manufacturers may offer competitive pricing, but local suppliers often excel in customization and speedy service. Evaluate the total value proposition to determine which option aligns best with your operational goals.

Pros and Cons of Overseas Suppliers

Advantages of Local Customization and Quick Service

These considerations help ensure that you receive not only a high-quality product but also reliable support and service.

Buyer’s Checklist: 10 Questions to Ask Manufacturers

A thorough vetting process is essential before finalizing any purchase. Asking the right questions can be the difference between a successful investment and a regrettable misstep.

Critical Questions Before Finalizing a Purchase

Inquire about the machine’s daily processing capacity, versatility in handling different meat types, and the availability of remote technical support. These queries ensure that the equipment aligns perfectly with your operational requirements.

What’s the Machine’s Daily Processing Capacity?

Can It Handle Multiple Meat Types?

Is Remote Technical Support Available?

These questions form the backbone of a sound purchasing decision, ensuring that every critical aspect is addressed before commitment.

Final Tips for Making an Informed Decision

A judicious approach to purchasing can secure both value and performance.

Avoiding Common Mistakes and Securing the Best Value

Meticulous research and thorough testing are indispensable. Prioritize safety and compliance over a lower price tag, and always test the machine with your specific meat types before finalizing your decision.

Prioritize Safety and Compliance Over Price

Test the Machine with Your Specific Meat Types

Negotiate Warranties and Service Contracts

These steps guarantee that your investment is both resilient and tailored to your unique operational demands.

Conclusion

Empowering your business with the right frozen meat dicing machine partner is not merely an upgrade—it is a transformative step toward enhanced efficiency, precision, and sustainability. With advanced engineering, robust support, and a keen eye for customization, these machines are poised to revolutionize meat processing in commercial kitchens and factories around the globe. Embrace the future of food preparation and secure a competitive edge with a machine that is as dynamic and forward-thinking as your business.

Must-Read Blogs For Chain Restaurants Owner

Sausage Stuffer Machine

Sausage Stuffer Machine Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

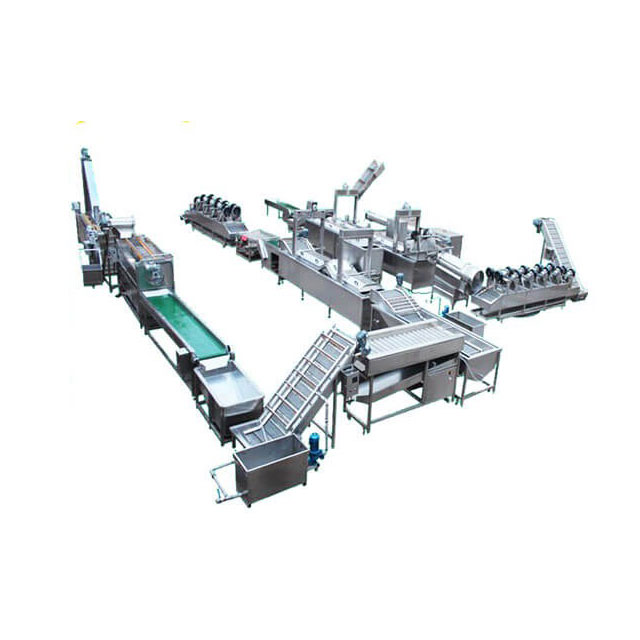

Chicken Plucker Machine Frozen French Fries Production Line

Frozen French Fries Production Line

Ready to Get Started?