The Definitive Guide to Meat Processing Equipment Procurement: Ensuring Quality, Efficiency, and Compliance

Introduction

In the dynamic landscape of meat processing, strategic equipment procurement isn’t merely a cost center – it’s the bedrock of operational success. The right machinery dictates production capacity, product quality, food safety, and ultimately, profitability. Navigating this complex process requires a nuanced understanding of your facility’s needs, a keen eye for technological advancements, and a commitment to long-term sustainability. This comprehensive guide will illuminate the critical considerations for procuring meat processing equipment, empowering you to make informed decisions that drive efficiency and bolster your market position.

The Importance of Equipment Procurement for Meat Processing Plants & Selecting the Right Tools for Success

A meat processing plant’s efficacy is inextricably linked to the quality and suitability of its equipment. Suboptimal choices can lead to bottlenecks, inconsistent product characteristics, increased waste, and potential food safety hazards. Conversely, investing in the right machinery unlocks enhanced throughput, superior product consistency, reduced labor costs, and a strengthened competitive edge. Selecting equipment isn’t about simply acquiring the newest technology; it’s about identifying solutions that seamlessly integrate into your workflow and address your specific operational challenges. Prioritize equipment that minimizes manual intervention, maximizes yield, and ensures adherence to stringent hygiene standards.

Understanding the Meat Processing Plant’s Production Flow

From Raw Material Reception to Finished Product Packaging – The Critical Steps

The meat processing journey is a meticulously orchestrated sequence of steps. It begins with the rigorous inspection and reception of raw materials, followed by pre-processing stages like deboning, trimming, and grinding. Subsequent phases involve marination, forming, heat treatment (cooking, smoking, or drying), chilling, and finally, precise packaging. Each stage demands specialized equipment, and a thorough understanding of this interconnected flow is paramount for optimizing overall efficiency. Identifying potential chokepoints and areas for improvement within this process will directly inform your equipment selection.

Different Scale Plants, Different Needs

The equipment requirements of a small, artisanal butcher shop differ dramatically from those of a large-scale, high-volume processing facility. Smaller operations often prioritize versatility and affordability, leaning towards manually operated or semi-automatic equipment. Larger plants, however, benefit from fully automated, high-throughput systems designed for continuous operation. Scalability is also crucial. Consider whether your current equipment can accommodate anticipated growth, or if future upgrades will be necessary. A phased approach to equipment acquisition, aligning with projected demand, can be a prudent strategy.

Formulating a Procurement Plan: Key Considerations

Budget Allocation: Balancing Cost and Quality

Establishing a realistic budget is the foundational step. Resist the allure of the lowest price tag. A false economy can result in unreliable equipment, frequent breakdowns, and ultimately, higher long-term costs. Focus on the total cost of ownership – factoring in the initial purchase price, installation, maintenance, energy consumption, and potential downtime. A robust cost-benefit analysis is essential.

Plant Space & Equipment Layout Compatibility

Ensure your facility has sufficient space to accommodate the chosen equipment, allowing for adequate workflow and maintenance access. A poorly planned layout can lead to congestion, safety hazards, and reduced efficiency. Consider ergonomic principles to minimize worker strain and optimize movement. Utilize floor plans and simulations to visualize the layout before committing to purchases.

Future Business Expansion & Equipment Upgrade Potential

Anticipate future growth and select equipment that can be readily adapted or upgraded to meet evolving demands. Modular designs and compatibility with future technologies are valuable attributes. Investing in equipment with upgrade paths can prevent costly replacements down the line.

Diverse Types of Meat Processing Equipment & Their Functions

Cutting Equipment: Precision and efficiency are paramount. Consider band saws, portion control saws, and waterjet cutters. The choice of blade material and sharpness directly impacts yield and product appearance. Invest in high-quality blades and establish a regular sharpening schedule.

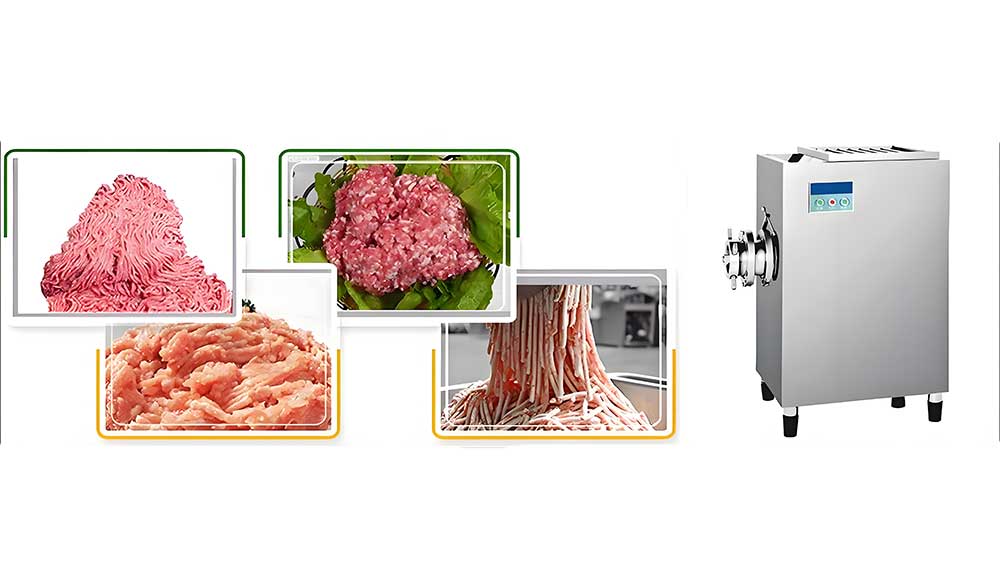

Grinding & Mixing Equipment: Achieving a consistent texture and thorough mixing of ingredients is vital. Grinder plate size dictates the fineness of the grind, impacting the final product’s mouthfeel. Ensure easy disassembly for thorough cleaning and sanitation.

Marination & Seasoning Equipment: Automation ensures consistent flavor profiles. Vacuum tumblers are particularly effective for enhancing marinade penetration. Consider equipment with programmable cycles for precise control.

Thermal Processing Equipment: Steamers, smokers, ovens, and fryers each impart unique characteristics. Understanding the nuances of each method is crucial for achieving desired product attributes. Energy efficiency and temperature control are key considerations.

Refrigeration & Freezing Equipment: Maintaining precise temperature control is non-negotiable for preserving product quality and safety. Energy-efficient systems are essential for minimizing operating costs. Invest in reliable temperature monitoring systems.

Packaging Equipment: Vacuum packaging extends shelf life, while automated labeling machines enhance presentation and traceability. Consider equipment that can accommodate various packaging formats.

Equipment Materials & Hygiene Standards

The Necessity of Food-Grade Stainless Steel

Stainless steel is the gold standard for meat processing equipment. Its corrosion resistance, ease of cleaning, and non-reactive properties are essential for maintaining hygiene and preventing bacterial contamination. Avoid materials prone to rust or harboring microorganisms. Look for 304 or 316 stainless steel grades for optimal performance.

Ensuring Compliance with International Food Safety Certifications (HACCP, ISO 22000, GMP)

Equipment must meet rigorous food safety standards. Look for certifications like HACCP (Hazard Analysis and Critical Control Points), ISO 22000, and GMP (Good Manufacturing Practices). These certifications demonstrate a commitment to food safety and quality. Verify that the equipment’s design facilitates thorough cleaning and sanitation.

Automation & Intelligent Equipment: The Future of Processing

Reducing Labor Costs & Increasing Production Efficiency

Automation minimizes manual intervention, reducing labor costs and increasing throughput. Automated systems can operate continuously, maximizing production capacity.

Smart Monitoring & Data Analysis for Production Process Optimization

Intelligent systems provide real-time data on key performance indicators, enabling proactive adjustments and optimized production processes. Data analytics can identify areas for improvement and optimize resource allocation.

The Application of Robotics in Meat Processing

Robotic arms are increasingly employed for tasks like deboning, portioning, and packaging, enhancing precision and reducing the risk of repetitive strain injuries. Robotics can also improve hygiene by minimizing human contact with the product.

Brand & Supplier Selection: A Strategic Partnership

Local Suppliers vs. International Brands: Weighing Quality & Price

Local suppliers offer responsiveness and potentially lower shipping costs, while international brands may provide access to cutting-edge technology and specialized expertise. Consider the long-term value proposition of each option.

Evaluating Supplier Credibility: Case Studies & Market Reputation

Thoroughly vet potential suppliers. Check references, review case studies, and assess their market reputation. Look for suppliers with a proven track record of reliability and customer satisfaction.

The Importance of After-Sales Service: Spare Parts Supply & Technical Support

Reliable after-sales service is critical. Ensure the supplier offers readily available spare parts, prompt technical support, and comprehensive training. A strong service network can minimize downtime and ensure continued operation.

Equipment Energy Efficiency & Environmental Standards

How Energy-Efficient Equipment Reduces Long-Term Operating Costs

Investing in energy-efficient equipment reduces electricity consumption and lowers operating costs. Look for equipment with energy-saving features and certifications.

The Impact of Environmental Regulations on Meat Processing Equipment

Compliance with environmental regulations is paramount. Consider equipment that minimizes water usage, reduces waste generation, and controls pollutant emissions.

Wastewater Treatment & Pollutant Emission Control

Effective wastewater treatment systems are essential for minimizing environmental impact. Ensure your equipment complies with local and national environmental regulations.

(The remaining sections – Installation & Debugging, Training & Operation, Maintenance & Servicing, Common Procurement Pitfalls, Case Studies, Negotiation Tactics, Regulations, Emergency Plans, Future Trends – remain as previously detailed.)

FAQ - Common Questions Answered

How do I choose equipment suitable for a small processing plant?

For smaller operations, prioritize versatility and affordability. Look for multi-functional equipment that can handle various tasks. Consider used or refurbished equipment in good condition to reduce initial costs. Focus on manual or semi-automatic options that require less upfront investment and are easier to maintain. Don’t overspend on features you won’t utilize.

If my budget is limited, how can I balance equipment quality and production needs?

Prioritize essential equipment first – those directly impacting food safety and core production processes. Explore leasing options or financing plans to spread out costs. Consider purchasing used equipment from reputable sources with warranties. Focus on durable, reliable brands known for longevity, even if they aren’t the most technologically advanced.

Is the maintenance cost of meat processing equipment high?

Yes, maintenance can be significant. However, proactive maintenance can minimize costly repairs. Regular cleaning, lubrication, and inspections are crucial. Factor maintenance costs into your total cost of ownership calculations. Choose equipment with readily available spare parts and a reliable service network.

What are the key points of equipment maintenance and how can I reduce maintenance costs?

Establish a preventative maintenance schedule. Train employees on proper operation and cleaning procedures. Regularly inspect equipment for wear and tear. Use genuine spare parts. Keep detailed maintenance records. Address minor issues promptly to prevent them from escalating.

Which is more cost-effective – imported or domestically produced equipment?

There’s no definitive answer. Imported equipment often offers advanced technology at a lower price point, but may have longer lead times and higher shipping costs. Domestic equipment offers faster delivery, easier access to service, and potentially better support. Evaluate your specific needs and prioritize factors like reliability, service availability, and long-term cost of ownership.

From a performance, cost, and after-sales perspective, what are the pros and cons?

| Feature | Imported Equipment | Domestic Equipment |

| Performance | Often technologically advanced | Generally reliable, may lag in innovation |

| Cost | Typically lower upfront | Often higher upfront |

| After-Sales | Can be slower, language barriers | Faster, easier communication |

| Lead Time | Longer | Shorter |

| Spare Parts | Potential delays | Readily available |

What food safety certifications are required for equipment procurement?

Look for equipment certified to HACCP, ISO 22000, and GMP standards. Ensure the equipment is constructed from food-grade materials (primarily stainless steel) and designed for easy cleaning and sanitation. Verify that the equipment meets relevant regulatory requirements in your region.

How can I assess the reliability of a supplier’s equipment?

Request references from other customers. Visit their facilities to see the equipment in operation. Review case studies and testimonials. Check online reviews and industry forums. Ask detailed questions about the equipment’s specifications, warranty, and service support. Conduct a thorough site visit to the supplier’s manufacturing facility.

Is it worth buying used equipment?

Used equipment can be a cost-effective option, but it comes with risks. Thoroughly inspect the equipment for wear and tear. Request a maintenance history. Obtain a warranty from the seller. Consider the age of the equipment and the availability of spare parts. Engage a qualified technician to assess its condition before purchasing.

Is it worth investing in intelligent equipment?

Intelligent equipment offers long-term cost benefits through increased efficiency, reduced labor costs, and improved data analysis. However, the initial investment is higher. Conduct a thorough ROI analysis to determine if the benefits outweigh the costs. Consider your long-term growth plans and the potential for future automation.

Can I lease processing equipment instead of buying it?

Yes, leasing is a viable option, especially for startups or businesses with limited capital. Leasing offers flexibility, lower upfront costs, and predictable monthly payments. However, you won’t own the equipment at the end of the lease term.

How can I prevent discovering a mismatch between purchased equipment and production needs?

Conduct a thorough needs analysis before procurement. Define your production requirements, throughput goals, and product specifications. Visit trade shows and demonstrations to see equipment in action. Request a trial period or pilot test before making a final purchase.

Summary

Equipment procurement is a pivotal decision that profoundly impacts the long-term trajectory of a meat processing plant. By embracing a strategic, data-driven approach, prioritizing quality and hygiene, and fostering strong supplier relationships, you can unlock enhanced production efficiency, superior product quality, and a sustainable competitive advantage. The labyrinthine world of equipment procurement demands diligence and foresight, but the rewards – a thriving, future-proof operation – are well worth the effort.

Must-Read Blogs For Chain Restaurants Owner

Portable Flake Ice Machine

Portable Flake Ice Machine Pelmeni Making Machine

Pelmeni Making Machine

Ready to Get Started?