Tackling Frozen Beef Head-On: Your Guide to the Best Dicing Equipment!

Frozen Solid? No Problem! Dicing Frozen Beef Just Got Easier

Let’s face it, dealing with large blocks of frozen beef can feel like preparing for an arctic expedition. It’s tough, time-consuming, and often, downright frustrating. Manually hacking away at a frozen block is not only inefficient but can be perilous. But what if I told you there’s a way to conquer those icy behemoths with relative ease? Modern food processing technology has ushered in specialized equipment designed specifically to tackle the unique challenge of dicing frozen beef, turning a daunting task into a streamlined, manageable process. Get ready to say goodbye to strenuous sawing and hello to perfectly uniform frozen beef dice!

Why Even Tackle Frozen Beef Dicing? The Perks You Might Be Missing!

You might wonder, "Why not just thaw the beef first?" While thawing has its place, dicing beef while frozen (or partially frozen) offers some distinct advantages, particularly in commercial settings. Processing meat at lower temperatures significantly mitigates bacterial growth, enhancing food safety – a paramount concern. Frozen dicing often results in cleaner, more defined cuts because the firmness prevents the meat from tearing or smushing under the blades. It also allows for longer storage life of the diced product in its frozen state and can streamline certain production workflows by eliminating the thawing step entirely. Embracing frozen dicing can unlock efficiencies and quality improvements you hadn't considered.

The Chilling Challenge: Why Your Standard Dicer Shivers at Frozen Beef

Here’s the crux of the matter: your standard, run-of-the-mill meat dicer is simply not engineered for the Herculean task of cutting through frozen blocks. Attempting to dice solidly frozen beef with equipment designed for chilled or fresh meat is a recipe for disaster. The immense resistance offered by frozen protein can lead to motor burnout, shattered blades, or even catastrophic frame damage. Standard dicers lack the requisite power, blade strength, and overall structural integrity to handle the frigid, unyielding nature of frozen beef. It’s like asking a scooter to pull a freight train – the mismatch in capability is profound.

Enter the Titans: Heavy-Duty Equipment Built for the Freeze

Fortunately, engineers love a challenge! Recognizing the need for robust processing solutions, manufacturers have developed a category of heavy-duty dicing equipment specifically designed to withstand the rigors of frozen meat processing. These aren't your average kitchen gadgets; they are industrial powerhouses, veritable titans built with reinforced components and formidable power systems. They are meticulously designed to slice through frozen blocks with precision and endurance, day in and day out.

What Makes a Dicer "Frozen Beef Ready"? Key Features to Demand

So, what elevates a dicer to "Frozen Beef Ready" status? It's a combination of specific design elements working in concert. Mere robustness isn't enough; it requires a specific panoply of features engineered for this demanding application. Understanding these key characteristics is vital when selecting the right machine for your frosty challenge.

The Powerhouse Within: Why Motor Strength is Non-Negotiable for Frozen Blocks

At the heart of any frozen meat dicer is its motor. Cutting through dense, frozen beef requires significantly more torque and horsepower than processing chilled meat. Look for machines boasting high-powered motors, often with specifications clearly indicating their suitability for frozen product processing. An underpowered motor will inevitably struggle, leading to inefficiency, potential overheating, and premature failure. Sufficient power is the absolute foundation upon which effective frozen dicing is built.

Blades of Glory: The Secret Weapon Against Rock-Hard Beef

Standard blades will dull, chip, or even shatter against frozen beef. Dicers designed for frozen applications utilize specialized blades crafted from exceptionally hard, durable materials, often treated for enhanced strength and resilience. The blade design itself might also be different – thicker, with reinforced edges and specific cutting angles optimized to cleave through ice crystals and dense muscle tissue efficiently and cleanly. These aren't mere cutting implements; they are purpose-built surgical instruments for frozen blocks.

Built Like a Tank: Construction That Laughs at Low Temperatures

Beyond the motor and blades, the entire machine frame and cutting chamber must be exceptionally robust. Think heavy-gauge stainless steel, reinforced welds, and structural designs capable of absorbing the significant vibrations and stresses generated during the dicing of hard, frozen blocks. Flimsy construction will quickly succumb to the relentless demands of this application. Durability isn't a luxury; it's an operational necessity.

Chill Out Factor: Ensuring Your Machine Handles the Cold

Operating in cold environments and processing frozen products means the machine itself must be resilient to low temperatures. Components like bearings, seals, and even lubricants need to be rated for cold-temperature operation to prevent seizing or malfunction. The materials used must resist becoming brittle in the cold. An efficacious frozen meat dicer is comfortable operating in the very conditions that define its workload.

Safety First, Always: Essential Mechanisms for Frozen Meat Processing

Given the power involved and the nature of the material being processed, safety is paramount. Look for comprehensive safety features: robust guarding around all cutting zones, emergency stop buttons that are easily accessible, safety interlocks that prevent operation if guards are open or removed, and potentially, load sensors to prevent dangerous overfeeding. Protecting operators is non-negotiable when dealing with such powerful machinery.

Meet Your Match: The Specialized Frozen Meat Dicer

This brings us to the star of the show: the specialized frozen meat dicer. These machines integrate all the aforementioned features – powerful motors, specialized blades, robust construction, cold-temperature resilience, and comprehensive safety mechanisms – into a cohesive unit designed for one primary purpose: efficiently and safely dicing frozen meat, including beef. They represent a targeted solution to a specific processing challenge.

How Frozen Meat Dicers Conquer the Cold: The Inside Scoop

These machines employ a combination of brute force and intelligent design. The immense power drives the specialized blades through the frozen block with relentless determination. The cutting action is often designed to minimize friction and heat generation, preserving the frozen state as much as possible during the brief cutting interval. Feed mechanisms are robust, ensuring consistent pressure against the cutting blades without overwhelming the system. It's a finely tuned choreography of power and precision.

More Than Just Muscle: The Unique Mechanics of Frozen Dicing

It's not just about being stronger. The mechanics often involve specific blade movements or sequences. Some machines might use a powerful guillotine action, while others employ rotating blade sets designed to chip away or progressively slice through the block. The goal is always to achieve a clean cut through the heterogeneous structure of frozen meat and ice crystals without shattering the block uncontrollably or generating excessive heat.

Unlock the Benefits: Why the Right Machine is a Game-Changer

Investing in a dedicated frozen meat dicer isn't just about overcoming a challenge; it's about unlocking significant operational benefits that can positively impact your bottom line and product quality. It transforms a laborious bottleneck into a smooth, efficient process.

Flawless Frozen Dice: Achieving Uniformity Against the Odds

Despite the hardness of the material, specialized frozen meat dicers excel at producing remarkably uniform dice. This consistency is crucial for portion control in packaged goods, even cooking in foodservice applications, and overall product appeal. The precision engineering ensures that even rock-solid blocks yield neat, consistently sized pieces.

Save Time, Save Sweat: Reclaiming Hours from Manual Labor

Compare the speed of automated dicing to manual cutting or even using inadequate equipment. The difference is staggering. A dedicated frozen meat dicer can process large quantities of beef in a fraction of the time, freeing up valuable labor hours for other critical tasks. It’s a quantum leap in productivity.

Safety Elevated: Ditch the Danger of Manual Frozen Block Cutting

Manually cutting frozen blocks with knives or saws is inherently hazardous, carrying a high risk of slips, cuts, and severe injuries. Automating this process with a properly guarded, purpose-built machine drastically reduces operator exposure to these dangers, creating a much safer working environment.

Maximize Your Meat: Reducing Waste and Improving Yield

Inconsistent manual cutting often leads to significant waste in the form of unusable shards or oddly shaped pieces. The precision of a frozen meat dicer minimizes this waste, ensuring more of your valuable beef ends up as usable product. Better yield translates directly to better profitability.

Keep It Cool: Maintaining Product Quality During Dicing

Because these machines work quickly and are designed to minimize friction, they help maintain the low temperature of the beef throughout the dicing process. This is critical for inhibiting bacterial proliferation and preserving the quality, texture, and shelf life of the final diced product.

Choosing Your Frozen Beef Warrior: Finding the Perfect Fit

Ready to enlist a frozen beef dicer? Selecting the right model requires careful consideration of your specific operational needs and constraints. It’s not a one-size-fits-all scenario.

Scale Up or Keep It Small? Matching Capacity to Your Needs

Assess your current and projected processing volumes. Dicers come in various sizes and throughput capacities, measured in kilograms or pounds per hour. Choose a machine that comfortably meets your peak demand without being excessively oversized (and overpriced) for your typical needs. Underestimating capacity leads to bottlenecks, while overestimating wastes capital.

Size Matters: Getting the Exact Dice Dimensions You Need

What size dice do you require for your recipes or products? Most frozen meat dicers offer interchangeable cutting grids or adjustable blade sets to produce various dice dimensions (e.g., 10mm, 15mm, 20mm cubes). Ensure the machine you choose can reliably produce the specific sizes you need.

Clean Machine, Happy Kitchen: Prioritizing Easy Sanitation

Even heavy-duty machines need rigorous cleaning. Look for designs that prioritize ease of sanitation. Features like quick-release components, smooth stainless steel surfaces, minimal crevices where debris can hide, and good access to the cutting chamber significantly simplify the cleaning process, ensuring food safety compliance.

Budgeting for the Best: Balancing Cost and Capability

Specialized frozen meat dicers represent a significant investment. Establish a realistic budget, but don't sacrifice essential features or build quality solely for a lower price. Consider the total cost of ownership, including potential maintenance and longevity. Often, investing more upfront in a higher-quality, more durable machine pays dividends in the long run.

Support System: Checking Warranty and Manufacturer Backing

Evaluate the manufacturer's reputation, the warranty offered, and the availability of technical support and spare parts. Reliable after-sales support can be invaluable if issues arise, minimizing potential downtime. A strong support system provides peace of mind for your critical equipment.

Pro Tips for Perfect Frozen Beef Dicing

Owning the right machine is half the battle; using it correctly ensures optimal results.

The Sweet Spot: Finding the Ideal Temperature for Cutting

While designed for frozen beef, there's often an ideal temperature range for the best cutting performance – typically not rock-solid deep freeze (-18°C or 0°F), but slightly tempered (perhaps -4°C to -8°C or 18°F to 25°F). This "sweet spot" varies by machine and beef type. Consult the manufacturer's recommendations and experiment to find what yields the cleanest cut with the least strain on the equipment.

Pre-Game Prep: Any Steps Before Dicing?

Ensure the frozen beef blocks are relatively uniform in shape if possible, and free from excessive surface ice or packaging materials before feeding them into the dicer. Some larger machines may require blocks to be pre-cut into manageable sizes that fit the feed chute. Always follow the manufacturer's guidelines for preparation.

Keeping Your Champion Strong: Maintenance Must-Dos

Adhere strictly to the manufacturer's recommended maintenance schedule. This includes regular cleaning, lubrication of moving parts (with food-grade lubricant), inspection of blades for sharpness and damage, and checking safety features. Preventative maintenance is key to longevity and reliable performance.

Frequently Asked Questions (FAQ)

Can I Really Not Use My Regular Dicer for Frozen Beef?

We strongly advise against it. As outlined earlier, standard dicers lack the power, blade strength, and structural integrity. Attempting it will likely damage your machine, void warranties, create safety hazards, and produce poor results. It's simply not worth the risk. Use the right tool for the job!

What's the Absolute Best Temperature to Dice Frozen Beef?

There isn't one single "absolute best" temperature, as it depends on the specific machine, blade type, and the desired dice size. However, most manufacturers recommend a range slightly below freezing, often between -4°C and -8°C (18°F to 25°F). This provides enough firmness for clean cuts without being so hard it excessively strains the equipment. Always refer to your machine's manual.

Are These Heavy-Duty Machines a Nightmare to Clean?

Manufacturers understand the critical importance of sanitation in food processing. While these are robust machines, reputable brands design them with ease of cleaning in mind. Look for features like removable panels, quick-release blade sets, polished surfaces, and designs that minimize hidden areas. Regular, thorough cleaning is essential, but good design makes it manageable, not a nightmare.

How Safe Are These Powerful Frozen Meat Dicers?

When sourced from reputable manufacturers and operated according to instructions, these machines are designed with operator safety as a top priority. Standard safety features include comprehensive guarding, emergency stops, and safety interlocks. Proper training and adherence to safety protocols are, of course, crucial for safe operation.

What Dice Sizes Can I Typically Expect?

Most frozen meat dicers offer flexibility through interchangeable cutting sets. Common dice sizes range from around 5mm up to 25mm or even larger, depending on the model. Check the specifications of the machine you are considering to ensure it can produce the dimensions you require.

Beyond Beef: Can They Dice Other Frozen Goodies?

Many heavy-duty dicers designed for frozen beef can also handle other firm or frozen products, such as frozen poultry, pork, certain types of firm cheese, or even some dense vegetables. However, always confirm the machine's capabilities with the manufacturer before attempting to process materials other than what it's primarily designed for.

Conclusion: Stop Fighting Frozen Beef, Start Dicing it Right!

Dicing frozen beef doesn't have to be an arduous, dangerous chore. By investing in specialized, heavy-duty dicing equipment designed for the task, you can transform this challenging process into an efficient, safe, and productive part of your operation. These powerful machines deliver consistent results, enhance food safety, reduce labor costs, and improve yield. Stop battling those icy blocks with inadequate tools and embrace the technology built to conquer the cold.

Ready to Conquer Frozen Beef? Find Your Dicing Solution Today!

If you're ready to upgrade your frozen beef processing capabilities, explore the range of specialized frozen meat dicers available. Consider your volume, required dice size, budget, and prioritize machines built for durability, safety, and ease of cleaning. Reach out to reputable equipment suppliers to discuss your specific needs and find the perfect frozen beef warrior for your kitchen or processing facility. Your future self (and your bottom line) will thank you!

Must-Read Blogs For Chain Restaurants Owner

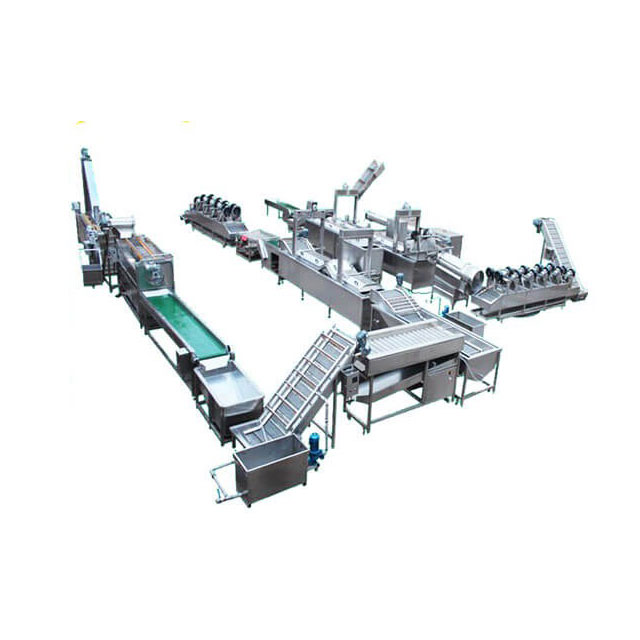

Frozen French Fries Production Line

Frozen French Fries Production Line Frozen Meat Ribs Dicing Machine

Frozen Meat Ribs Dicing Machine Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Frozen Meat Roll Cutting Machine

Frozen Meat Roll Cutting Machine

Ready to Get Started?