Navigating the Apex of Throughput: Equipment Solutions for the Modern Abattoir

The Relentless Demand: Why High Capacity is King in Large Meat Processing

In the contemporary globalized economy, the exigency for meat products burgeons ceaselessly, placing immense pressure on large-scale abattoirs to amplify their output. The confluence of burgeoning populations, evolving dietary predilections, and the imperatives of efficient supply chains necessitates an unwavering focus on maximizing processing capacity. For these behemoths of the food industry, achieving peak throughput is not merely an operational objective; it is the sine qua non for sustained viability and market dominance. The ability to process substantial volumes of livestock expeditiously and effectively translates directly into enhanced profitability, responsiveness to consumer demand, and the fortification of a robust market presence.

The Equipment Imperative: Laying the Foundation for Massive Output

The attainment of prodigious processing volumes in modern meat processing plants hinges critically upon the deployment of sophisticated and purpose-built equipment. The infrastructure underpinning these high-capacity operations transcends mere machinery; it constitutes an intricate ecosystem of interconnected technologies designed to optimize every facet of the production lifecycle, from the initial reception of livestock to the final dispatch of packaged goods. Without a meticulously curated assemblage of cutting-edge apparatus, the aspiration of achieving and sustaining high throughput remains an unattainable chimera. The selection and strategic implementation of the correct equipment are therefore paramount, forming the very bedrock upon which operational efficacy and prodigious output are constructed.

Navigating the Complexities: Our Guide to High-Capacity Solutions

The journey toward establishing a high-capacity meat processing facility is fraught with intricate decisions and technological considerations. Discerning the optimal suite of equipment necessitates a comprehensive understanding of the diverse stages involved in meat processing, coupled with an acute awareness of the latest advancements in abattoir technology. This compendium serves as an authoritative guide, illuminating the critical equipment solutions that empower large-scale meat processors to navigate these complexities and achieve the zenith of their production potential. We shall traverse the entire spectrum of operations, from the initial receipt of livestock to the final stages of packaging and dispatch, elucidating the pivotal role of specialized machinery in realizing unparalleled throughput.

Streamlining Arrival: Automated Unloading and Sorting Systems

The initial ingress of livestock into a high-capacity facility demands efficiency and precision. Automated unloading systems, employing hydraulic platforms and guided conveyors, facilitate the swift and safe transfer of animals from transport vehicles, minimizing stress and potential injury. Subsequently, sophisticated sorting systems, utilizing optical scanners and weight sensors, automatically categorize livestock based on predefined criteria such as species, size, and condition. This automated triage expedites the subsequent processing stages and ensures optimal flow within the abattoir.

Comfort First, Quality Always: Humane Handling in Holding Areas

Prior to processing, the welfare of the animals is of paramount ethical and operational significance. Modern holding areas are meticulously designed to provide a comfortable and low-stress environment. Features such as climate control systems, ample space, and automated feeding and watering mechanisms contribute to the well-being of the livestock. Furthermore, strategically designed pen layouts and guiding systems facilitate the smooth and humane movement of animals toward the stunning area, minimizing agitation and ensuring a tranquil transition into the processing stream.

The First Line of Defense: Cleaning and Health Inspection Technologies

Maintaining impeccable hygiene and ensuring the health of the processed meat necessitates rigorous pre-processing protocols. Automated washing systems, employing high-pressure sprays and antimicrobial solutions, thoroughly cleanse the animals before they enter the primary processing line. Concurrently, advanced health inspection technologies, including veterinary oversight and remote sensing capabilities, identify any animals exhibiting signs of illness or injury, ensuring that only healthy specimens proceed further into the production cycle.

The Science of Humane Stunning: Ensuring Ethical Practices

The ethical imperative of humane stunning is non-negotiable in contemporary meat processing. Advanced stunning systems, employing controlled atmosphere stunning (CAS) for poultry and swine, or electrical or captive bolt stunning for bovine, render animals instantaneously insensible to pain and distress. These scientifically validated methods prioritize animal welfare while maintaining the efficiency required for high-capacity operations. Continuous monitoring and data logging systems ensure that stunning procedures adhere to stringent ethical and regulatory standards.

Precision Bleeding: Optimizing Yield and Hygiene

Following stunning, the exsanguination process must be executed with both precision and rapidity to optimize meat yield and maintain hygienic conditions. Automated bleeding lines, incorporating specialized shackles and strategically positioned incision points, facilitate efficient blood drainage. Enclosed blood collection systems minimize the risk of contamination and enable the recovery of blood for use in other applications, contributing to a more sustainable operation.

Skinning and Dehiding Mastery: Automated Solutions for Speed and Cleanliness

The removal of hides or feathers is a critical step in preparing the carcass for further processing. Automated dehiding machines for bovine and swine, utilizing mechanical rollers and blades, perform this task with remarkable speed and efficiency, significantly reducing manual labor requirements and minimizing the risk of carcass damage. For poultry, automated plucking machines employ a series of rotating drums with rubber fingers to swiftly and cleanly remove feathers, ensuring a high level of hygiene and throughput.

Evisceration Excellence: Streamlining Internal Organ Removal

The removal of internal organs, or evisceration, is a delicate yet crucial stage that demands both speed and precision to prevent contamination. Automated evisceration systems, employing robotic arms and guided tools, perform this task with remarkable dexterity and efficiency. These systems often incorporate sophisticated inspection mechanisms to identify any abnormalities in the viscera, ensuring that only healthy carcasses proceed to the next stage of processing.

The Art of Splitting: Precision Saws for Optimal Division

The longitudinal division of the carcass into halves, or splitting, is a fundamental step in facilitating subsequent cutting and deboning operations. High-precision band saws, often equipped with laser guidance systems, ensure accurate and consistent splitting, minimizing bone fragments and maximizing meat yield. Automated splitting lines can process a high volume of carcasses per hour, contributing significantly to overall throughput.

Washing Away Worries: Automated Carcass Cleaning Systems

Maintaining impeccable hygiene throughout the processing cycle is paramount. Automated carcass washing systems, employing a series of strategically positioned spray nozzles delivering water at controlled temperatures and pressures, effectively remove any residual contaminants from the carcass surface. These systems are often integrated with antimicrobial application mechanisms to further enhance food safety.

Chilling for Quality: Rapid and Efficient Cooling Technologies

The rapid reduction of carcass temperature is critical for inhibiting microbial growth and preserving meat quality. Advanced chilling technologies, such as spiral chillers and blast chillers, rapidly lower the temperature of carcasses to the required levels. These systems are designed for high throughput and ensure uniform cooling throughout the carcass, contributing to extended shelf life and enhanced product safety.

Eyes on the Prize: Visual Inspection Systems for Flawless Products

Even with automation, meticulous inspection remains a cornerstone of quality assurance. High-resolution visual inspection systems, often employing cameras and sophisticated image analysis software, scrutinize carcasses and meat cuts for any visual defects, such as bruising, discoloration, or foreign material. These systems provide an objective and consistent assessment, ensuring that only products meeting stringent quality standards proceed further.

Beyond the Surface: Advanced Fat Content Analysis

Meeting consumer demand for specific fat content levels requires precise analytical tools. Advanced fat content analysis equipment, utilizing technologies such as near-infrared spectroscopy or computer tomography, provides rapid and accurate measurements of fat composition within meat cuts. This data enables processors to categorize and market their products effectively, catering to diverse consumer preferences.

Temperature and pH Monitoring: Guardians of Freshness

Maintaining optimal temperature and pH levels throughout the processing and storage phases is crucial for preserving meat freshness and preventing spoilage. Real-time temperature and pH monitoring systems, employing sensors embedded within the production line and storage facilities, provide continuous data on these critical parameters. Automated alerts notify personnel of any deviations from the established thresholds, allowing for timely corrective action.

Grading with Precision: Automated Systems for Consistent Quality

To ensure consistent product quality and meet market specifications, automated grading systems are indispensable. These systems integrate data from various inspection points, including visual assessments, fat content analysis, and weight measurements, to assign a grade to each carcass or meat cut. This automated classification ensures uniformity and facilitates efficient inventory management and pricing strategies.

Slicing Through Complexity: High-Precision Cutting Saws

The subsequent fabrication of carcasses into primal and sub-primal cuts demands precision and efficiency. High-precision band saws and circular saws, often equipped with automated guides and indexing systems, enable the accurate and rapid division of meat into specific portions. These automated cutting solutions minimize waste and maximize the yield of valuable cuts.

The Bone Brigade: Automated Deboning Robots for Maximum Yield

The removal of bones from meat cuts, or deboning, is a labor-intensive task that can be significantly streamlined through automation. Sophisticated deboning robots, equipped with articulated arms and specialized cutting tools, can precisely separate meat from bone with remarkable speed and accuracy. These robotic systems significantly increase yield and reduce the reliance on manual labor, contributing to enhanced efficiency and cost-effectiveness.

Trimming Triumph: Conveyor Systems for Efficient Meat Separation

Following deboning, meat cuts often require trimming to remove excess fat and connective tissue. Automated trimming conveyor systems facilitate this process by presenting meat cuts to operators in an ergonomic and efficient manner. Integrated weighing and sorting mechanisms allow for the rapid categorization of trimmed meat based on quality and intended use.

Standardization at Scale: Automated Portioning and Sizing

Meeting the demands of retail and foodservice customers often requires meat products to be portioned and sized to precise specifications. Automated portioning machines, utilizing laser scanning and high-speed blades, can accurately cut meat into predetermined weights and dimensions. This standardization ensures consistent product presentation and simplifies inventory management for downstream customers.

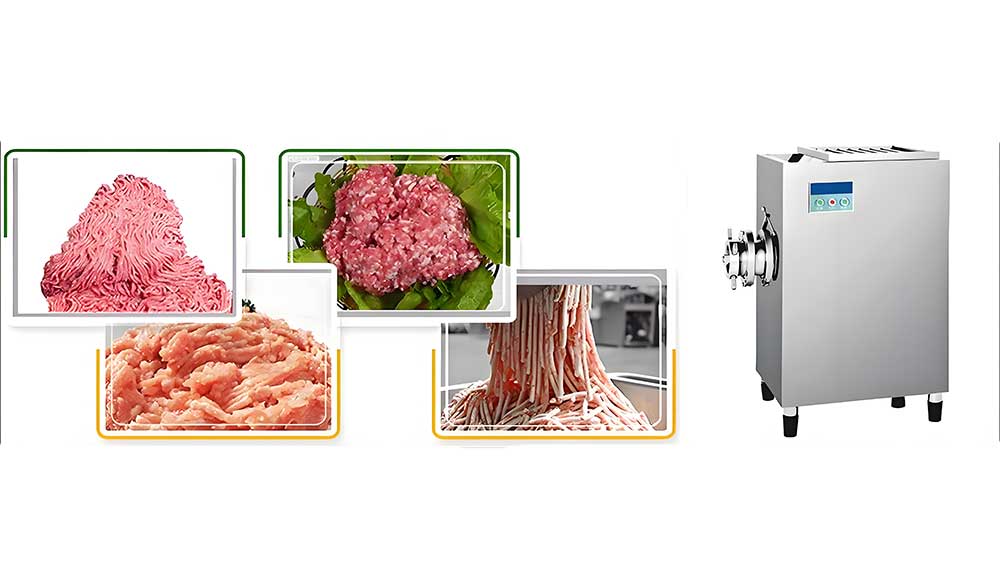

The Power of the Grind: Industrial Grinders for Massive Output

The production of ground meat, a ubiquitous staple in many diets, necessitates high-capacity grinding equipment. Industrial grinders, featuring robust motors and large-diameter grinding plates, can process substantial volumes of meat quickly and efficiently. Advanced models often incorporate features such as pre-breakers and temperature control mechanisms to ensure optimal grinding quality and prevent product degradation.

Blending Perfection: High-Volume Mixing Solutions

For the production of sausages, meatloaf, and other comminuted meat products, thorough and consistent mixing is paramount. High-volume industrial mixers, often featuring twin-shaft or ribbon blending mechanisms, can efficiently combine meat with seasonings, binders, and other ingredients. Automated loading and unloading systems further enhance the throughput of these mixing operations.

Emulsifying Expertise: Achieving Fine Textures for Processed Meats

Certain processed meat products, such as frankfurters and bologna, require an extremely fine and homogenous texture achieved through emulsification. Industrial emulsifiers, employing high-speed rotors and stators, can reduce particle size and create stable emulsions from meat, fat, and water. These machines are designed for continuous operation and high throughput, essential for large-scale production.

Vacuum Technology: Enhancing Quality and Shelf Life

The application of vacuum technology plays a crucial role in enhancing the quality and extending the shelf life of various meat products. Vacuum tumblers facilitate the efficient marination and tenderization of meat by creating a vacuum that opens up muscle fibers. Vacuum stuffers are used in sausage production to eliminate air pockets, resulting in denser and more uniform products.

Shaping Success: Automated Patty and Meatball Forming

The efficient production of formed meat products, such as patties and meatballs, is facilitated by automated forming machines. These machines can produce a high volume of uniformly shaped and sized products, reducing manual labor and ensuring consistency. Adjustable dies allow for the creation of various shapes and sizes to meet diverse customer requirements.

Sausage Sensations: High-Speed Filling and Linking

The production of sausages, a globally popular meat product, benefits significantly from automated filling and linking machines. These high-speed systems can precisely fill sausage casings with meat emulsion and then automatically link or twist the sausages into predetermined lengths. This automation drastically increases production speed compared to manual methods.

The Flavor Infusion: Automated Marinating and Tumbling

Enhancing the flavor and tenderness of meat through marination is a common practice. Automated marinating and tumbling systems, often operating under vacuum, ensure that marinades are evenly distributed throughout the meat, maximizing flavor absorption and reducing processing time. These systems are designed for large-scale operations and can handle substantial volumes of product.

Smoking and Cooking at Scale: Industrial Ovens and Smokers

The cooking and smoking of meat products at an industrial scale require specialized equipment capable of handling large volumes and ensuring consistent results. Industrial ovens and smokers, often featuring automated temperature and humidity controls, can cook or smoke vast quantities of meat simultaneously. Programmable cycles ensure uniform processing and adherence to specific product requirements.

Wrapping Wonders: High-Speed Flow Wrapping Solutions

The primary packaging of individual meat portions or products is often accomplished using high-speed flow wrapping machines. These versatile machines form a flexible package around the product and seal it, providing protection and extending shelf life. They are capable of handling a wide variety of product sizes and shapes at impressive speeds.

Vacuum Victory: Extending Shelf Life with Automated Vacuum Packaging

For products requiring an extended shelf life, automated vacuum packaging machines are indispensable. These machines remove air from the package before sealing, creating an anaerobic environment that inhibits microbial growth and preserves product freshness. High-speed vacuum packaging lines can efficiently process large volumes of meat products.

Modified Atmosphere Magic: MAP Packaging for Optimal Preservation

Modified atmosphere packaging (MAP) involves altering the composition of the atmosphere inside the package to extend shelf 1 life and maintain product quality. Automated MAP packaging machines precisely control the mixture of gases (typically carbon dioxide, nitrogen, and oxygen) introduced into the package before sealing, creating an optimal environment for preservation.

Shrink Wrapping Solutions: Enhancing Presentation and Protection

Shrink wrapping provides a tight and protective layer around packaged meat products, enhancing their presentation and providing tamper evidence. Automated shrink wrapping machines pass the packaged product through a heat tunnel, causing the film to shrink tightly around the product. These systems can be integrated with other packaging equipment for a seamless operation.

Labeling with Lightning Speed: Automated Application Systems

Accurate and efficient labeling is crucial for providing consumers with essential product information. Automated labeling systems can apply labels to packaged meat products at high speeds, ensuring correct placement and readability. These systems can often print variable data, such as weight and sell-by dates, on the labels in real time.

Boxing and Palletizing Power: Streamlining End-of-Line Operations

The final stages of packaging involve preparing products for shipment. Automated boxing and palletizing systems take the finished, labeled packages and automatically load them into cartons or onto pallets. This automation significantly reduces manual labor and streamlines the logistics of moving products out of the processing plant.

The Conveyor Command: Seamless Transportation Throughout the Plant

An efficient material handling system is the circulatory system of a high-capacity meat processing plant. Extensive networks of conveyors, in various forms such as belt, roller, and overhead, facilitate the continuous movement of carcasses, meat cuts, and packaged products between different processing stages. This automated transportation minimizes manual handling and ensures a smooth and uninterrupted flow of production.

Warehouse Wonders: Automated Storage and Retrieval Systems (AS/RS)

For large-scale operations, efficient storage of raw materials, semi-finished goods, and finished products is essential. Automated storage and retrieval systems (AS/RS) utilize robotic cranes and computer-controlled racking to store and retrieve items with speed and precision. These systems maximize storage density and minimize the time required to locate and retrieve products.

Autonomous Allies: The Role of AGVs and Robotics in Material Movement

Beyond fixed conveyor systems, autonomous guided vehicles (AGVs) and mobile robots are increasingly being deployed in meat processing plants for flexible material handling tasks. These autonomous units can navigate the facility floor, transporting materials between different areas without human intervention. They offer a versatile solution for tasks such as delivering packaging materials to packaging lines or moving finished goods to the loading dock.

CIP Champions: Automated Clean-in-Place Systems

Maintaining the highest standards of hygiene requires thorough and efficient cleaning. Automated clean-in-place (CIP) systems are designed to clean and sanitize enclosed processing equipment, such as pipelines, tanks, and filling machines, without the need for disassembly. These systems circulate cleaning solutions and sanitizers through the equipment, ensuring a consistent and validated cleaning process.

COP Conquerors: Clean-Out-of-Place Solutions for Thoroughness

For equipment components that require disassembly for thorough cleaning, clean-out-of-place (COP) systems provide an effective solution. These systems typically involve immersing disassembled parts in heated cleaning solutions within specialized tanks, followed by rinsing and sanitization. COP systems ensure that all surfaces of the equipment are properly cleaned, minimizing the risk of contamination.

High-Pressure Hygiene: Powerful Cleaning Technologies

For cleaning larger surfaces and removing stubborn residues, high-pressure cleaning systems are indispensable. These systems utilize powerful jets of water, often mixed with detergents or sanitizers, to effectively clean floors, walls, and the exterior surfaces of equipment. Mobile high-pressure units provide flexibility in cleaning various areas of the processing plant.

Sanitation Specialists: Advanced Disinfection Equipment

Beyond cleaning, effective disinfection is crucial for eliminating pathogenic microorganisms. Advanced disinfection equipment, such as ultraviolet (UV) light sanitizers, ozone generators, and fogging systems, can be used to further reduce the microbial load in the processing environment. These technologies provide an additional layer of protection to ensure food safety.

Personal Hygiene Protocols: Ensuring Employee Compliance

While automated systems play a significant role in maintaining hygiene, the adherence of personnel to strict personal hygiene protocols is equally important. Automated handwashing and sanitizing stations, boot washes, and gowning procedures are essential components of a comprehensive hygiene program. Monitoring systems can track employee compliance with these protocols.

Environmental Monitoring: Proactive Measures for a Safe Facility

To ensure the effectiveness of hygiene and sanitation efforts, comprehensive environmental monitoring programs are implemented. This involves regular sampling and testing of surfaces, air, and water for the presence of microorganisms. Automated environmental monitoring systems can provide real-time data, allowing for the prompt identification and remediation of any potential contamination issues.

The Importance of Pure Water: Advanced Filtration and Purification

Water is an essential resource in meat processing, used for cleaning, chilling, and various other applications. Advanced water filtration and purification systems, such as reverse osmosis and ultraviolet disinfection, ensure that the water used throughout the facility meets the highest quality standards. This is crucial for both product quality and food safety.

Wastewater Wisdom: Efficient Treatment and Discharge

Meat processing generates significant volumes of wastewater that must be treated effectively before discharge. Advanced wastewater treatment systems, employing a combination of physical, chemical, and biological processes, remove contaminants and ensure that the effluent meets stringent environmental regulations. Efficient wastewater management is a key aspect of sustainable operations.

Closing the Loop: Water Recycling and Reuse Strategies

In regions facing water scarcity or with a strong commitment to sustainability, water recycling and reuse strategies are becoming increasingly important in meat processing plants. Advanced treatment technologies can purify wastewater to a level suitable for reuse in non-product contact applications, such as cleaning floors or cooling towers, significantly reducing overall water consumption.

Breathing Easy: Advanced Air Filtration Systems

Maintaining optimal air quality within the processing facility is important for both product quality and employee health. Advanced air filtration systems, incorporating HEPA filters and other specialized media, remove airborne particles and microorganisms, minimizing the risk of contamination and creating a healthier working environment.

Temperature Taming: Precision Climate Control

Maintaining precise temperature control throughout the various processing stages is crucial for product quality and safety. Sophisticated climate control systems, including refrigeration units and HVAC systems, ensure that different areas of the plant are maintained at the optimal temperature for the specific operations being performed. Automated monitoring and adjustment mechanisms ensure consistent conditions.

Ventilation Victory: Ensuring Optimal Airflow and Quality

Proper ventilation is essential for removing excess heat, humidity, and odors from the processing environment. High-efficiency ventilation systems, designed to provide adequate air exchange rates, contribute to a comfortable and hygienic working environment. Strategically placed air inlets and outlets ensure optimal airflow throughout the facility.

The Power of MES: Real-Time Production Tracking

Modern meat processing plants generate vast amounts of data. Manufacturing execution systems (MES) collect and analyze this data in real time, providing valuable insights into production performance. MES can track everything from raw material usage to finished product output, enabling managers to identify bottlenecks, optimize processes, and improve overall efficiency.

Quality Command Center: Comprehensive Data Management Systems

Beyond production tracking, comprehensive data management systems are essential for maintaining quality standards and ensuring traceability. These systems integrate data from various sources, including quality control checks, inspection results, and laboratory analyses, providing a holistic view of product quality throughout the entire processing lifecycle.

Predictive Power: Equipment Condition Monitoring

Unexpected equipment failures can lead to costly downtime. Predictive maintenance programs, utilizing sensors and data analytics, monitor the condition of critical equipment components in real time. By identifying potential issues before they lead to breakdowns, predictive maintenance minimizes disruptions to production and extends the lifespan of equipment.

Traceability Titans: Ensuring Product Accountability

In the event of a food safety issue, the ability to quickly and accurately trace products back to their source is paramount. Robust traceability systems, utilizing unique identifiers and digital records, track the movement of raw materials and finished products throughout the entire supply chain. This accountability is essential for protecting consumers and maintaining brand trust.

Sorting for Success: Efficient Waste Segregation Systems

Meat processing inevitably generates waste. Efficient waste segregation systems, employing automated sorting technologies and clear labeling protocols, enable the separation of different types of waste streams, such as organic materials, packaging materials, and recyclables. This segregation facilitates proper disposal and maximizes the potential for recycling or further processing.

Rendering Riches: Converting By-products into Valuable Materials

Many by-products generated during meat processing, such as bones, fat, and offal, can be rendered into valuable materials like animal feed ingredients, tallow, and protein meals. Automated rendering systems efficiently process these by-products, reducing waste and generating additional revenue streams for the processing plant.

Sustainable Solutions: Minimizing Environmental Impact

Modern meat processing plants are increasingly focused on minimizing their environmental footprint. Sustainable solutions, such as anaerobic digestion for biogas production from organic waste and the use of environmentally friendly refrigerants, are being adopted to reduce energy consumption, greenhouse gas emissions, and overall environmental impact.

Powering Progress Responsibly: Energy-Efficient Equipment Choices

Energy costs represent a significant portion of the operating expenses for large meat processing plants. Selecting energy-efficient equipment, such as high-efficiency motors, variable frequency drives, and optimized refrigeration systems, can significantly reduce energy consumption and lower operating costs.

Reducing the Footprint: Minimizing Water and Resource Consumption

Beyond energy, water and other resource consumption are also key areas of focus for sustainability efforts. Implementing water-saving technologies, such as low-flow cleaning nozzles and water recycling systems, and optimizing the use of packaging materials can significantly reduce the environmental footprint of meat processing operations.

Embracing Renewables: Exploring Sustainable Energy Options

Some forward-thinking meat processing plants are exploring the use of renewable energy sources, such as solar panels or wind turbines, to power their operations. While the initial investment may be substantial, renewable energy can provide long-term cost savings and reduce reliance on fossil fuels, contributing to a more sustainable and resilient operation.

What is the typical ROI for investing in high-capacity meat processing equipment?

The return on investment (ROI) for high-capacity meat processing equipment is contingent upon a multitude of factors, including the initial capital expenditure, the scale of operations, labor cost savings, enhanced production efficiency, reduced waste, and the prevailing market prices for meat products. Generally, facilities implementing comprehensive automation can anticipate a significant reduction in operational costs and a substantial increase in throughput, leading to a compelling ROI within a timeframe of typically three to seven years. A meticulous cost-benefit analysis, tailored to the specific circumstances of the processing plant, is crucial for accurately projecting the anticipated return.

How do I determine the right equipment capacity for my plant's needs?

Determining the optimal equipment capacity necessitates a thorough evaluation of current and projected production volumes. Factors such as anticipated daily and weekly throughput, the diversity of product offerings, seasonal fluctuations in demand, and potential for future expansion must be meticulously considered. Engaging with experienced equipment suppliers and conducting simulations of the production process can provide valuable insights into selecting equipment with the appropriate capacity to meet both immediate and long-term operational requirements without incurring unnecessary capital costs associated with over-specified machinery.

What are the key considerations for integrating new equipment with existing lines?

The seamless integration of new, high-capacity equipment into an existing processing line demands meticulous planning and a comprehensive understanding of the current infrastructure. Key considerations include the physical footprint of the new equipment, its compatibility with existing conveyor systems and material handling processes, the electrical and utility requirements, and the control system interfaces. Collaboration with both the equipment manufacturer and internal engineering teams is paramount to ensure a harmonious and efficient integration that minimizes disruption to ongoing operations.

How can automation improve food safety in a large meat processing plant?

Automation plays a pivotal role in enhancing food safety within large meat processing facilities by minimizing human contact with the product, thereby reducing the potential for microbial contamination. Automated cleaning and sanitation systems ensure consistent and thorough hygiene protocols. Furthermore, advanced inspection technologies can identify and remove contaminated products with greater accuracy and speed than manual inspection, contributing to a significantly safer end product.

What are the latest technological advancements in meat processing equipment?

The meat processing equipment sector is characterized by continuous innovation. Recent technological advancements include the proliferation of sophisticated robotics for deboning and cutting, the integration of artificial intelligence and machine learning for enhanced quality control and predictive maintenance, the development of more energy-efficient and sustainable processing technologies, and the increasing adoption of digital platforms for real-time monitoring and data analytics. Remaining abreast of these technological evolutions is crucial for maintaining a competitive edge.

What are the maintenance requirements for high-capacity processing equipment?

High-capacity meat processing equipment, characterized by its intricate mechanics and demanding operational schedules, necessitates a robust and proactive maintenance regimen. This typically encompasses regular lubrication, inspection of wear components, calibration of sensors and control systems, and adherence to the manufacturer's recommended maintenance protocols. Implementing a preventative maintenance program, coupled with readily available spare parts and skilled maintenance personnel, is essential for maximizing equipment uptime and longevity.

How can I ensure my equipment choices align with animal welfare standards?

Ensuring that equipment choices align with animal welfare standards requires prioritizing technologies that minimize stress and discomfort for livestock throughout the processing cycle. This includes selecting humane stunning systems, implementing gentle handling mechanisms in receiving and holding areas, and designing processing lines that facilitate a smooth and unhurried flow of animals. Consulting with animal welfare experts and adhering to relevant industry guidelines are paramount in this regard.

What are the regulatory compliance aspects to consider when selecting equipment?

The meat processing industry is subject to stringent regulatory oversight concerning food safety, hygiene, and environmental impact. When selecting equipment, it is imperative to ensure compliance with all applicable local, national, and international regulations. This includes verifying that equipment is constructed from food-grade materials, adheres to sanitary design principles, and meets environmental standards for emissions and waste disposal. Thorough due diligence and consultation with regulatory bodies are essential.

How can data analytics help optimize equipment performance and production?

The integration of data analytics into meat processing operations offers profound opportunities for optimizing equipment performance and overall production efficiency. By collecting and analyzing data from various sensors and control systems, processors can gain valuable insights into equipment utilization rates, identify potential bottlenecks in the production flow, predict maintenance needs, and optimize process parameters for maximum yield and quality.

What are the best practices for training staff on new automated equipment?

The successful implementation of new automated equipment hinges upon the provision of comprehensive and effective training for operating personnel. Best practices include a combination of theoretical instruction, hands-on training under the guidance of experienced technicians, and the provision of readily accessible training materials and ongoing support. A well-trained workforce is essential for maximizing the benefits of automation and ensuring the safe and efficient operation of the equipment.

The Future of High-Capacity Meat Processing: Embracing Innovation

The trajectory of high-capacity meat processing is inextricably linked to the relentless march of technological innovation. The future will likely witness even greater integration of robotics, artificial intelligence, and the Internet of Things (IoT) to further optimize efficiency, enhance food safety, and promote sustainability. Facilities that proactively embrace these advancements will be best positioned to thrive in an increasingly competitive and demanding marketplace.

Investing in Efficiency: A Path to Sustainable Growth

Investing in high-capacity meat processing equipment is not merely an expenditure; it is a strategic imperative for achieving sustainable growth and long-term success in the industry. The enhanced efficiency, reduced operating costs, improved product quality, and enhanced food safety afforded by modern equipment provide a compelling return on investment and lay a solid foundation for future prosperity.

Partnering for Progress: Choosing the Right Equipment and Suppliers

The selection of the right equipment and, equally importantly, the right equipment suppliers, is a critical decision for any large meat processing operation. Establishing a collaborative partnership with reputable and experienced suppliers who can provide not only high-quality machinery but also comprehensive after-sales support, technical expertise, and ongoing innovation is paramount for achieving sustained operational excellence and navigating the evolving landscape of the meat processing industry.

Must-Read Blogs For Chain Restaurants Owner

Sausage Stuffer Machine

Sausage Stuffer Machine Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine Poultry Feather Removal Machine

Poultry Feather Removal Machine

Ready to Get Started?