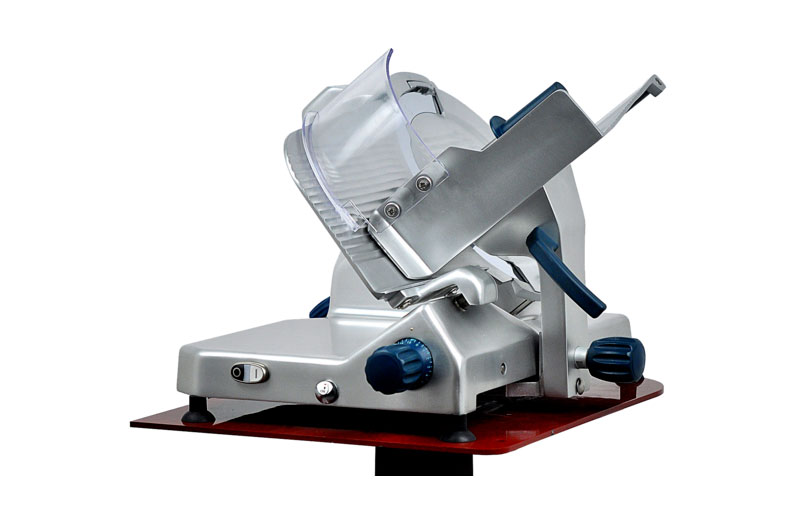

Mastering Meat Slicer Machines: The Ultimate Guide for Professionals

1. Mastering Meat Slicer Machines: A Professional’s Guide to Selection, Safety, and Maintenance

Key Factors to Consider When Choosing a Meat Slicer Machine: Blade Type, Power, and Capacity

Selecting the right meat slicer machine requires careful consideration of blade type, power, and capacity:

Blade Types :

- Advantage : Quickly switch between slice thicknesses (e.g., thin vs. thick cuts).

- Recommended Models : Waring 6520, Amaco 2020.

- Pros : Retain sharpness longer, ideal for frequent use.

- Maintenance Tip : Wipe dry immediately after use to prevent rust.

- Use Case : Commercial kitchens processing large volumes of meat (e.g., ham, beef).

- Pros : Durable and corrosion-resistant, ideal for high-humidity environments.

- Cons : May require more force for hard meats; best paired with electric models.

- Recommended Models : BUNN 7502, COSMOS CS-1000.

- Stainless Steel Blades :

- Carbon Steel Blades :

- Replaceable Blade Design :

Power (Wattage) :

- Example : Amaco 2020 for mid-sized restaurants.

- Example : Ninja Meat Master for home use.

- Home Models : 500–1000W (handles 5–10 lbs/hour).

- Commercial Models : 1500W+ (supports 10–20+ lbs/hour).

Capacity & Feed Opening :

- Home Models : 1–10mm.

- Commercial Models : 0.5–15mm.

- Standard Opening : 12 inches (suitable for most meat blocks).

- Large Capacity : 15 inches (ideal for whole turkeys or large cuts).

Thickness Range :

Safety Compliance Standards: OSHA Guidelines for Commercial Meat Slicer Operations

OSHA mandates the following safety requirements for commercial meat slicers:

Mechanical Safeguards :

- Auto-Retracting Blade : Automatically retracts after use to prevent accidental contact.

- Safety Guard : Closes automatically during operation; requires a two-handed start.

- OSHA Compliance : BUNN 7502 meets 29 CFR 1910.212 standards.

Employee Training :

- Training Modules :

- Documentation : Training records must be retained for at least 3 years.

- Safe operation (blade angle, feed speed).

- Emergency stop procedures (red button must trigger within 0.5 seconds).

- PPE requirements (anti-slip gloves, safety goggles).

Annual Safety Inspection :

- Blade guard integrity.

- Emergency stop response time.

- Electrical insulation testing (using a megohmmeter).

- Inspection Items :

- Certification : Must be performed by a certified engineer.

Maintenance Checklist: Daily Cleaning, Blade Sharpening, and Preventive Care

Daily Maintenance :

- Test : Place paper under the blade; it should cut easily.

- Visual Inspection : Look for cracks or rust.

- Steps :

- Blade Check :

- Unplug and disassemble removable parts (blade, conveyor belt).

- Soak in warm water + food-grade cleaner for 10 minutes.

- Wipe the body with a soft cloth; avoid water near the motor.

Weekly Maintenance :

- Apply NSF-certified lithium-based grease (e.g., White Lightning) to gears and slides.

- Avoid : WD-40 (contains solvents that corrode metal).

- Manual Sharpening : Use a 1200-grit stone (3–5 strokes in one direction).

- Electric Sharpeners : Align with blade angle (e.g., Waring sharpener).

- Blade Sharpening :

- Lubrication :

Annual Maintenance :

- Continuous cutting test (100 lbs of meat; blade temp ≤60°C).

- Motor load test (30 minutes at full capacity).

- Disassemble components and clean with an ultrasonic cleaner.

- Replace worn belts (e.g., Amaco genuine parts).

- Deep Cleaning :

- Performance Testing :

2. The Ultimate Meat Slicer Machine Buyer’s Guide: Expert Recommendations for Home & Commercial Use

Home vs. Commercial Meat Slicer Machines: Performance Differences and Cost Analysis

Home Models :

- Pros : 1000W power, removable blades; $299.

- Pros : Multi-functional (slicing, grinding, dicing); $199.

- Cons : 600W power limits continuous use.

- Ninja Meat Master :

- COSMOS CS-1000 :

Commercial Models :

- Advantage : IP55 waterproof rating reduces maintenance by 30%.

- Total Cost of Ownership :

- ROI : Saves $3,650/year by reducing labor costs ($0.5/lb savings).

- Machine cost: $1,899.

- Annual maintenance: $150 (lubricants, sharpening).

- Expected lifespan: 10 years.

- Amaco 2020 :

- Waring 6520 :

Top 5 Meat Slicer Brands Compared: Features, Durability, and Customer Reviews

Cost-Effective Commercial Models: High-Volume Options Under $2000

- Amaco 2020 Specifications :

- Blade Material : High-carbon steel, replaceable.

- Cutting Thickness : 0.5–15mm.

- Safety Features : Dual-layer guard, emergency stop.

- Warranty : 3-year parts, 1-year labor.

- Waring 6520 Advantages :

- Waterproof Design : IP55 rating allows direct rinsing.

- Energy Efficiency : Standby power ≤1W (saves $50/year).

3. Why Meat Slicer Machine Maintenance Matters: Tips from Industry Experts to Extend Lifespan

Common Maintenance Mistakes: Avoiding Blade Dulling and Corrosion

- Case Study : A restaurant neglected gear lubrication, causing bearing failure ($300 repair).

- Correct Procedures :

- Blade Dulling : Sharpen every 100 lbs of meat or monthly.

- Corrosion Prevention : Apply food-grade anti-rust oil (e.g., CRC 6-36) after cleaning.

Industry-Standard Maintenance Checklist: Monthly vs. Annual Servicing

4. Choosing the Right Meat Slicer Machine: A Deep Dive into Features, Brands, and Safety Standards

Blade Sharpness vs. Safety: Balancing Precision and Injury Prevention

Angle Guide :

Safety Design Example :

- BUNN 7502 : Safety guard requires manual pressing to open; blade retraction confirms with a "click" sound.

5. How to Optimize Meat Slicer Machine Performance: Pro Tips for Efficiency and Precision

Techniques for Consistent Slice Thickness: Blade Angle and Feed Speed Control

- Feeding Tips :

- Thin slices (2mm): Medium-low speed (100 RPM).

- Thick slices (5mm): Low speed (80 RPM).

- Secure meat with a non-slip mat or clamp.

- Speed Settings :

- Blade Angle Adjustment :

- Loosen the angle knob.

- Use a digital angle gauge to set the desired angle.

- Tighten the knob and test cuts.

6. Meat Slicer Machine Myths Debunked: Expert Insights on Common Misconceptions

Myth: "Manual Slicers Are Safer Than Electric Ones" – Fact or Fiction?

- OSHA Data : Manual slicers have twice the injury rate due to operator error.

- Case Study : A restaurant’s manual slicer injury led to $15,000 in worker’s compensation claims.

7. The Future of Meat Slicer Machines: Innovations and Trends Shaping the Industry

Smart Meat Slicers: IoT Integration for Real-Time Monitoring

- Technology :

- Sensors : Track blade temperature and cutting speed.

- App Features : Maintenance alerts and performance reports.

- Case Study : BUNN’s IoT-enabled model reduced downtime by 30% in 2024.

8. Frequently Asked Questions (FAQs) About Meat Slicer Machines: Expert Answers

How Often Should I Sharpen the Blade?

- Industry Standard : Every 100 lbs of meat or monthly.

- Blade Lifespan : High-carbon steel lasts 1 year; stainless steel lasts 2 years.

Is a Meat Slicer Safe for Home Use?

- Safety Certification : Look for UL-listed models (e.g., Ninja Meat Master).

Must-Read Blogs For Chain Restaurants Owner

Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Portable Flake Ice Machine

Portable Flake Ice Machine Pelmeni Making Machine

Pelmeni Making Machine

Ready to Get Started?