From Field to Fork: Exploring the World of Green Bean Processing Equipment

Green beans—those crisp, flavorful pods packed with nutrients—are a staple in cuisines around the world. But have you ever stopped to consider the journey these vegetables take from farm to your plate?

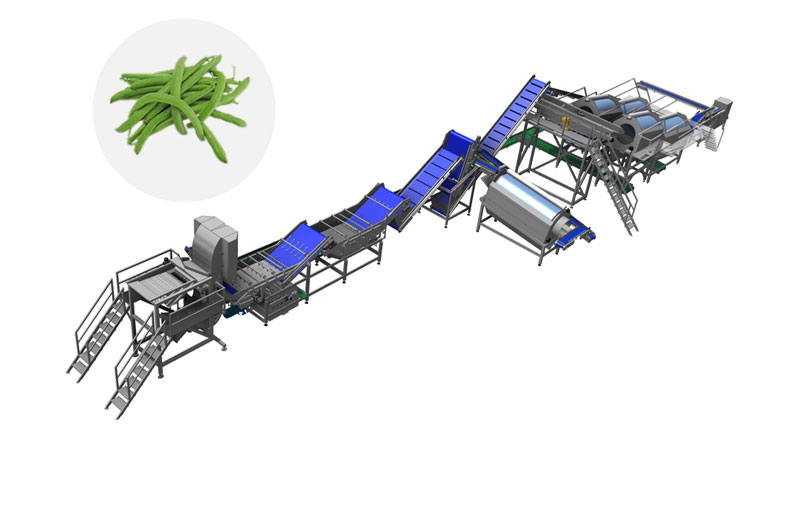

The transformation from freshly picked bean to the consistent, ready-to-enjoy products lining grocery store shelves is made possible by the magic of green bean processing equipment. This specialized machinery is vital for ensuring the quality, safety, and convenience of the green beans we consume. Whether you’re a food processing professional, an aspiring entrepreneur, or simply a curious foodie, join us as we delve into the fascinating world of green bean processing equipment.

Stage 1: Receiving & Cleaning – From Farm Fresh to Factory Ready

The process begins with fresh green beans arriving at the processing facility, often directly from the field.

Unloading & Receiving: Specialized equipment is used to gently unload and receive the green beans, minimizing damage and preserving their freshness.

Cleaning & Sorting: Next comes a critical step – removing any foreign material and ensuring that only the highest-quality beans proceed. This typically involves:

Dry Cleaning: Rotating drums or air blowers remove dirt, debris, and loose leaves.

Washing & Fluming: Gentle washing systems, utilizing water baths or sprays, thoroughly clean the beans. Flumes with flowing water help transport the beans and further remove any remaining debris.

Inspection & Sorting: Skilled workers or automated optical sorting machines identify and remove any discolored, damaged, or misshapen beans, ensuring only the best continue to the next stage.

Stage 2: Prepping for Perfection – Sizing, Snapping, and Cutting

Now that the green beans are clean and sorted, it’s time to prepare them for their final form.

Sizing: This step involves separating the beans based on their length, creating a more uniform final product. Sizing can be done manually or by utilizing automated systems with rollers or belts.

Snapping & Cutting: To remove the stem ends and, if desired, cut the beans into preferred lengths, specialized machinery comes into play:

Snappers: These machines efficiently remove the stem ends of the green beans, ensuring consistency and minimizing waste.

Cutters: If desired, green beans can be cut into specific lengths using rotary cutters or dicers.

Stage 3: Preservation Power – Blanching & Cooling

This crucial stage helps preserve the green beans' vibrant color, fresh flavor, and vital nutrients for long-lasting enjoyment.

Blanching: Green beans are briefly immersed in hot water or steam. This process deactivates enzymes that can cause spoilage and color deterioration during storage. Blanching also helps to preserve nutrients and reduce microbial load.

Cooling: After blanching, rapid cooling is essential to halt the cooking process and preserve the desired texture. This is typically achieved by utilizing cold water baths or air chilling systems.

Stage 4: The Final Touch – Packaging and Further Processing

Packaging: The processed green beans are now ready for packaging. Depending on the intended use and market demand, this might involve:

Canned: Packed in cans and sterilized for extended shelf life.

Frozen: Individually quick frozen (IQF) to preserve optimal texture and freshness.

Fresh-Cut: Packaged for refrigerated retail sale.

Further Processing: In some cases, green beans undergo additional processing after blanching and cooling, which can include:

French Cutting: Cut lengthwise into thin strips.

Dicing: Cut into small, uniform cubes.

Slicing: Sliced into round or diagonal pieces.

Choosing the Right Equipment – Key Considerations

Selecting the right green bean processing equipment depends on several crucial factors, including:

Production Volume: Small-scale operations might opt for manual or semi-automated equipment, while large-scale facilities require high-capacity, automated systems.

Desired Product: The intended final product format (canned, frozen, fresh-cut) will heavily influence equipment choices.

Budget & Space Constraints: Equipment costs vary significantly, as do space requirements for operation.

Maintenance & Sanitation: Easy-to-clean and easy-to-maintain equipment is vital for ensuring food safety and minimizing downtime.

Modern Innovations in Green Bean Processing

The world of green bean processing is constantly evolving, driven by technological advancements and a growing emphasis on efficiency and sustainability.

Optical Sorting: Advanced optical sorting machines, equipped with cameras and sensors, can identify and remove defective beans with remarkable accuracy, significantly reducing waste and enhancing product quality.

Water & Energy Efficiency: Modern processing equipment is often designed with sustainability in mind, incorporating water-saving features and energy-efficient technologies.

Automation & Robotics: Automated systems and robotics are becoming increasingly prevalent in green bean processing, streamlining operations, reducing labor costs, and improving consistency.

From the simple act of cleaning and sorting to sophisticated cutting and packaging techniques, green bean processing equipment plays an essential role in bringing these nutritious and versatile vegetables from the field to our tables. Whether enjoyed fresh, frozen, or canned, the next time you savor a green bean, take a moment to appreciate the intricate journey – and the remarkable machinery – involved in bringing it to your plate.

Must-Read Blogs For Chain Restaurants Owner

Sausage Stuffer Machine

Sausage Stuffer Machine Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine

Ready to Get Started?