Essential Benefits of Meat Paste Machines in Production Lines

Introduction to Meat Paste Machines

What is a Meat Paste Machine?

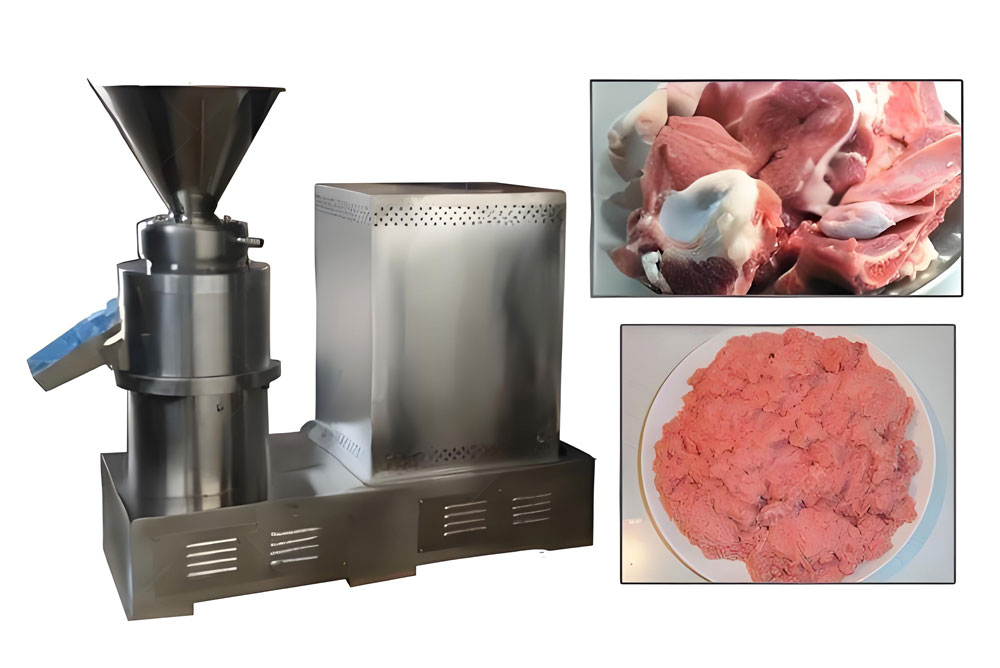

A meat paste machine is a specialized piece of equipment designed to process meat into a smooth, uniform paste or puree. This machine is commonly used in food processing industries for preparing products like sausages, patés, meatballs, and various ready-to-eat meals. By grinding, blending, and emulsifying meat, these machines ensure the meat is processed to a desired consistency, meeting both texture and safety standards.

Understanding the Role of Meat Paste Machines in Food Processing

Meat paste machines play an integral role in transforming raw meat into a form that can be further processed into various products. The process involves breaking down meat fibers into smaller particles, allowing the meat to blend seamlessly with other ingredients such as fats, spices, or vegetables. This improves the consistency and texture of the final product, making it easier to shape, cook, and package for consumers.

Why Meat Paste Machines Are Essential for Modern Meat Processing

In today’s fast-paced food industry, maintaining efficiency while ensuring high-quality meat products is paramount. Meat paste machines streamline production by automating the grinding and blending processes. This automation not only saves time but also reduces the risk of human error, ensuring consistency and enhancing product quality.

The Benefits of Using a Meat Paste Machine in Your Production Line

Using a meat paste machine in your production line offers several advantages. These include:

- Improved efficiency: The machine speeds up the processing time, allowing higher production output.

- Consistency: It ensures uniform texture and quality in each batch, leading to consistent product quality.

- Labor savings: Automated processes reduce the need for manual labor.

- Versatility: Capable of processing different types of meat, including beef, pork, chicken, and fish.

Key Features of a Meat Paste Machine

High-Speed Processing Capabilities

One of the standout features of modern meat paste machines is their ability to process large quantities of meat quickly. With advanced motors and efficient grinding systems, these machines significantly increase production speeds, making them ideal for high-volume operations.

Precision and Consistency in Paste Production

Precision is crucial when it comes to meat paste production. These machines are engineered to deliver uniform results with each batch, ensuring the meat is blended to the exact specifications required. The consistency in texture also ensures that the end product meets regulatory and quality standards.

Hygienic Design for Safe Food Processing

Given the importance of hygiene in food processing, meat paste machines are often designed with easy-to-clean surfaces, removable parts, and food-grade materials. This helps minimize contamination risks and complies with stringent food safety regulations.

Ease of Use: User-Friendly Controls and Automation

Most meat paste machines are equipped with user-friendly interfaces that make operation straightforward. Automated controls allow users to adjust settings such as grinding speed, blending consistency, and temperature. This simplicity helps reduce training time and ensures the machine can be used effectively by all operators.

Durability and Long-Term Performance

Meat paste machines are designed for durability. Built from high-quality materials, such as stainless steel, these machines are built to withstand the rigors of continuous use while maintaining optimal performance.

Types of Meat Paste Machines

Vertical Meat Paste Machines: Ideal for High-Capacity Production

Vertical meat paste machines are designed to process large volumes of meat quickly and efficiently. These machines are typically used in industrial settings where high production rates are essential. Their vertical orientation allows for larger capacity, making them ideal for high-throughput production.

Horizontal Meat Paste Machines: Versatility and Flexibility in Production

Horizontal meat paste machines offer greater flexibility and versatility. Their design allows for a variety of mixing, grinding, and blending processes, making them suitable for different types of meat paste products. These machines are typically smaller and more compact than their vertical counterparts, making them perfect for medium-sized operations.

Batch vs. Continuous Meat Paste Machines: Which One Suits Your Needs?

Batch machines operate by processing fixed quantities of meat at a time, while continuous machines run without interruption, processing meat continuously. Batch machines offer greater flexibility for small to medium operations, while continuous machines are best suited for large-scale, high-volume production.

Multi-Function Meat Paste Machines: Blending, Grinding, and More

Some meat paste machines come equipped with multiple functions. These multi-functional units combine grinding, blending, and emulsifying capabilities, providing a one-stop solution for meat paste production. This versatility can streamline production and reduce the need for multiple machines.

How a Meat Paste Machine Works

Step-by-Step Process of Making Meat Paste

The process begins by feeding raw meat into the machine's hopper. The meat is then ground into smaller particles through a series of sharp blades. Next, the meat is blended with other ingredients like fats and seasonings. Finally, the mixture is emulsified to achieve the smooth, uniform texture required for the final product.

The Role of Grinding and Blending in Paste Consistency

Grinding and blending are crucial to achieving the desired texture and consistency of the meat paste. Grinding breaks down the meat fibers, while blending ensures that fat, meat, and other ingredients combine evenly. This step is essential for creating a paste with a smooth texture that’s easy to work with and cook.

How Meat Paste Machines Ensure Uniform Texture and Quality

The uniformity of the texture is achieved through carefully calibrated grinding, blending, and emulsifying actions. Advanced technology allows the machine to maintain a consistent texture across large batches, eliminating the risk of uneven texture that can result from manual processes.

Understanding the Importance of Temperature Control in Paste Production

Maintaining the correct temperature during paste production is crucial. Excessive heat can cause the fat to melt and affect the texture of the paste. Meat paste machines come with temperature control systems that ensure the mixture stays at optimal conditions, preventing degradation of product quality.

Factors Affecting the Cost of a Meat Paste Machine

Machine Size and Capacity: How They Impact the Price

The size and capacity of the machine play a significant role in determining its price. Larger machines that can handle bigger quantities of meat and process at higher speeds tend to be more expensive. The cost also depends on the complexity of the machine’s features and capabilities.

Material Quality: The Role of Stainless Steel and Other Durable Materials

Material quality is an important factor in the overall durability and price of the machine. Stainless steel is commonly used due to its resistance to corrosion and ease of cleaning. Machines made with high-quality materials tend to have a longer lifespan and require less maintenance.

Automation Features: How Technology Affects Cost

Automated features, such as programmable controls, touchscreens, and self-cleaning functions, add convenience but also increase the cost of the machine. Machines with advanced automation capabilities are often priced higher due to the increased technology and complexity involved.

Customization Options: Tailoring the Machine for Specific Needs

Many meat paste machines offer customization options to suit specific production needs. Whether it’s a unique blade configuration or specific motor capacity, customization can increase the cost, but it also ensures the machine performs exactly as required for your production line.

Brand Reputation and Its Effect on Pricing

Brand reputation plays a significant role in pricing. Established brands known for their quality, reliability, and after-sales service often charge higher prices. However, the investment may be worthwhile, as these machines are built to last and come with robust support.

Choosing the Right Meat Paste Machine for Your Business

Assessing Production Needs: Small, Medium, or Large-Scale Operations?

Determining the scale of your operation is key to selecting the right meat paste machine. Smaller operations may only need a compact machine with lower processing capacities, while larger operations will require a high-volume, high-capacity machine that can handle continuous production.

Evaluating Production Capacity and Speed

Consider how quickly your production line needs to operate. If high throughput is required, you’ll need a machine with higher processing speeds. Evaluate whether a batch or continuous system is more suitable for your production demands.

Balancing Budget with Machine Features and Performance

While high-end machines with advanced features may be appealing, it’s essential to balance your budget with the required features. Focus on the performance aspects that are most critical to your production, such as capacity, texture consistency, and ease of maintenance.

Space Considerations: How Much Room Do You Need?

Space availability is an important factor when selecting a meat paste machine. Large machines with greater capacity require more floor space, so ensure you have enough room in your facility to accommodate the equipment.

Maintenance and Care of Meat Paste Machines

Routine Maintenance Practices for Long-Term Performance

Regular maintenance is vital for extending the life of your meat paste machine. This includes cleaning and lubricating moving parts, inspecting blades, and checking for any wear and tear. Proper maintenance helps prevent downtime and ensures optimal machine performance.

Cleaning and Sanitizing Your Meat Paste Machine

Sanitization is critical in meat processing to prevent contamination. Meat paste machines are designed to be easily cleaned, with many featuring removable parts and surfaces that facilitate thorough cleaning. Regular sanitization ensures the machine stays hygienic and compliant with food safety regulations.

Troubleshooting Common Issues with Meat Paste Machines

Common issues with meat paste machines include clogging, inconsistent paste texture, or motor malfunctions. Troubleshooting these problems often involves simple adjustments like cleaning out blockages, checking the grinding blades, or recalibrating the machine’s settings.

The Importance of Regular Inspections for Optimal Function

Routine inspections are key to preventing larger issues from arising. A professional inspection can help identify potential problems early, saving time and money in repairs and ensuring the machine remains in good working condition.

Frequently Asked Questions (FAQs)

What is a Meat Paste Machine?

A meat paste machine is a specialized piece of equipment used to grind and blend meat into a smooth paste. It is widely used in the meat processing industry to make meat fillings, sausages, and other meat-based products. The machine ensures a uniform texture and meets food safety standards through precise grinding and blending.

What are the primary functions of a Meat Paste Machine?

The primary function of a meat paste machine is to process meat by grinding, mixing, and blending it into a consistent paste. Many machines are equipped with temperature control systems to maintain optimal processing conditions, ensuring the quality and safety of the product.

Why are Meat Paste Machines crucial in modern meat processing?

As the food industry demands higher efficiency, hygiene, and quality, meat paste machines have become essential in modern meat processing. They enhance production efficiency, ensure product consistency, and minimize manual labor, helping to meet growing market demands.

What are the benefits of using a Meat Paste Machine?

- Increased production efficiency and faster processing times

- Consistent texture and quality of the meat paste

- Improved product taste and texture

- Reduced labor costs and higher automation levels

- Compliance with food safety and hygiene regulations, minimizing contamination risks

How does the high-speed processing capability of a Meat Paste Machine impact production?

Meat paste machines with high-speed processing capabilities can handle large volumes of raw material in a short period. This means businesses can produce more products in less time, significantly improving overall production line efficiency.

How do I choose the right Meat Paste Machine?

When selecting a meat paste machine, consider the following factors:

- Production needs: Small, medium, or large-scale operations?

- Machine capacity and speed: Match the machine’s output to your processing needs

- Budget: Balance the machine's features, performance, and cost

- Space: Evaluate the available space in your facility for installation

What maintenance and care does a Meat Paste Machine require?

Regular maintenance and care are essential to ensure the long-term performance of your meat paste machine. Routine maintenance includes:

- Regular cleaning and sanitization to prevent bacterial buildup

- Periodic inspection of mechanical parts to ensure proper function

- Preventing excessive wear and tear, especially on critical components like grinding blades and mixing elements

How can common issues with Meat Paste Machines, such as clogging or inconsistent texture, be fixed?

To fix common issues:

- Clogging: Often caused by high moisture content in the raw material or mechanical faults. Adjusting the moisture levels or cleaning out blockages can help.

- Inconsistent texture: May result from uneven mixing or temperature fluctuations. Ensure the mixing components are working properly and check the temperature control system.

How can I reduce energy consumption in my Meat Paste Machine?

To reduce energy consumption, choose energy-efficient meat paste machines with advanced control systems. Selecting machines with built-in energy-saving features, such as optimized motors and temperature control, can minimize unnecessary energy usage. Additionally, regular maintenance ensures the machine runs at peak efficiency.

How can I ensure my Meat Paste Machine complies with food safety standards?

To ensure compliance with food safety standards, the machine should be designed with hygiene in mind, using food-grade materials like stainless steel. The machine should also have cleaning and sanitizing features to meet the required hygiene standards and prevent contamination.

What types of Meat Paste Machines are available for different production needs?

Vertical Meat Paste Machines

Ideal for high-capacity production, these machines handle large volumes of raw materials efficiently.

Horizontal Meat Paste Machines

Offer versatility and flexibility in production, suitable for a variety of product types.

Batch vs. Continuous Meat Paste Machines

Batch machines are best for irregular production needs, while continuous machines are suited for large-scale, ongoing production.

Multi-Function Meat Paste Machines

These machines can perform multiple tasks, such as grinding, mixing, and blending, making them suitable for diverse production requirements.

How can I negotiate the best price for a Meat Paste Machine?

When negotiating with suppliers, inquire about the machine’s specifications and request a detailed quote. If possible, leverage bulk purchasing or long-term partnerships to obtain discounts and favorable terms.

What additional costs should I consider when purchasing a Meat Paste Machine?

Apart from the machine's base price, consider the following additional costs:

- Installation fees: Check if they are included in the quote or charged separately

- Maintenance and spare parts: Ongoing maintenance costs for machine upkeep

- Shipping and delivery fees: Depending on the distance from the supplier

- Energy consumption: Long-term energy costs based on the machine’s efficiency

What are the technological innovations in Meat Paste Machines?

Recent advancements in automation and control systems, such as artificial intelligence and IoT (Internet of Things), have significantly improved the functionality of meat paste machines. These technologies optimize production processes, enhance efficiency, and reduce human intervention, contributing to safer and more efficient production lines.

How can I ensure the quality and reliability of a Meat Paste Machine?

Choose reputable brands and certified manufacturers with a proven track record. Reviewing customer feedback and testimonials can provide insight into the machine's performance and reliability. Additionally, ensure the equipment meets all relevant safety certifications and food processing standards.

Must-Read Blogs For Chain Restaurants Owner

Portable Flake Ice Machine

Portable Flake Ice Machine Pelmeni Making Machine

Pelmeni Making Machine

Ready to Get Started?