Comparison of Different Brands of Tomato Paste Production Line Equipment

With the growing global demand for tomato products, the tomato paste production industry has seen rapid development. Automated production lines have become essential for enhancing efficiency, reducing labor costs, and ensuring product quality. Multiple brands on the market offer different models of tomato paste production line equipment, making it necessary for businesses to choose equipment that best suits their needs. In this article, we will compare various brands and models of tomato paste production lines from multiple perspectives, including performance, price, and technical support, to help users select the most suitable equipment.

I. Core Components of a Tomato Paste Production Line

Before diving into the brand comparisons, it’s important to understand the essential components of a tomato paste production line. These components are key to the production process and typically include:

Washing equipment: Cleans the tomatoes to remove impurities and conducts initial sorting.

Crusher: Breaks down the tomatoes to prepare for the concentration and filtration process.

Pre-heater: Prepares the tomato pulp by heating it to increase concentration efficiency.

Evaporator: Removes excess water from the tomato pulp, thickening it to the desired consistency.

Concentration equipment: Further removes water to ensure high-quality paste production.

Sterilizer: Sterilizes the final product to ensure safety and hygiene.

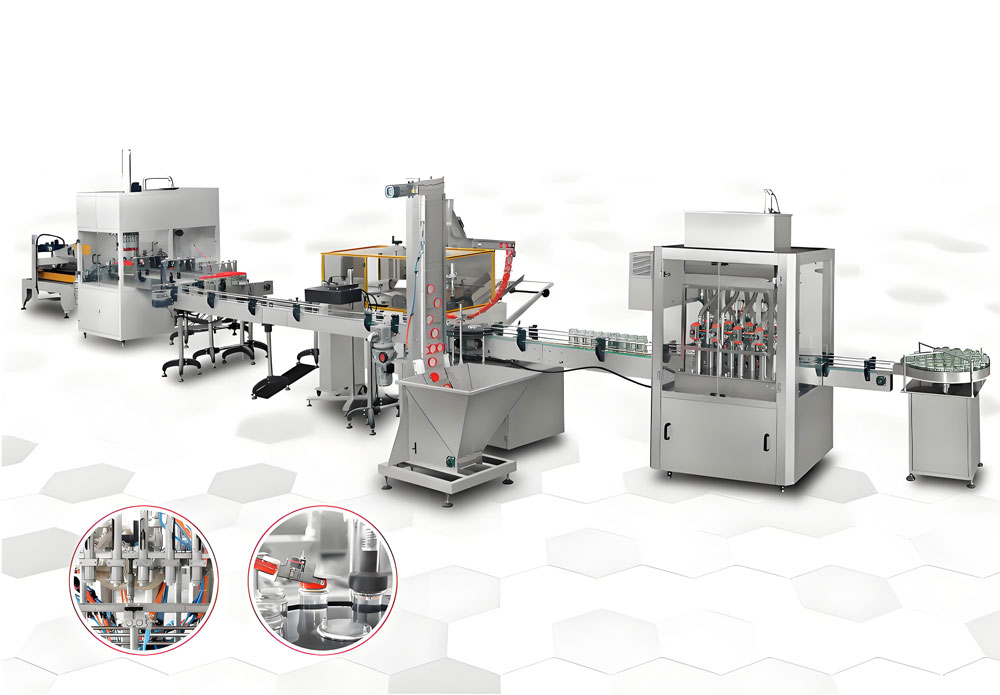

Filling machine: Automatically fills and seals the finished tomato paste into containers.

Different brands offer varying designs and functionalities for these components, and understanding these differences is crucial for making the right choice.

II. Comparison of Brands of Tomato Paste Production Line Equipment

1. Brand A: Goma Machinery

Goma Machinery is one of the global leaders in the food processing equipment industry, known for its experience and high-quality tomato paste production line systems. Their equipment stands out for its efficiency, stability, and high degree of automation.

Performance: Goma Machinery’s tomato paste production line is fully automated, integrating washing, crushing, evaporating, concentrating, and sterilizing functions. The equipment is highly efficient and suitable for large-scale industrial production. With a processing capacity of 10-20 tons per hour, it meets the needs of large enterprises. The system is also flexible and can be customized according to production requirements.

Price: The price of Goma Machinery's equipment is relatively high, ranging between $500,000 to $1,000,000. However, the long-term durability and high productivity of the system often justify this higher investment.

Technical Support: Goma Machinery offers global technical support, including installation, operational training, and after-sales maintenance. Their extensive support network ensures that customers receive timely technical assistance and equipment servicing.

Summary: Goma Machinery is ideal for enterprises prioritizing high production efficiency and stability, especially for large-scale processing plants. Despite the high initial cost, the equipment's performance and global technical support provide a long-term return on investment.

2. Brand B: Shanghai Chase

Shanghai Chase is a well-known food processing equipment manufacturer in China, focusing on providing cost-effective solutions for small and medium-sized food processing enterprises.

Performance: Shanghai Chase’s tomato paste production lines are known for their flexibility. The modular design allows businesses to adjust the production line based on their specific needs, offering versatile production solutions. With a processing capacity of 5-15 tons per hour, the equipment is well-suited for small and medium-scale production.

Price: Their equipment is more affordable, with prices ranging between $100,000 to $500,000. This makes Shanghai Chase an attractive option for businesses with more limited budgets.

Technical Support: Shanghai Chase provides comprehensive technical support across China, ensuring quick responses to equipment malfunctions and offering detailed training on operating the machinery.

Summary: Shanghai Chase is a top choice for small and medium-sized enterprises looking for affordable and flexible solutions. While the processing capacity and automation level are lower than some premium brands, their equipment is perfectly adequate for medium-scale production needs.

3. Brand C: Bertuzzi Food Processing

Bertuzzi Food Processing is based in Italy and is a leading global supplier of food processing equipment, specializing in high-performance equipment for medium to large enterprises.

Performance: Bertuzzi’s equipment is known for high efficiency and automated operation. Their advanced concentration technology and aseptic filling system produce top-quality tomato paste. With a processing capacity of over 20 tons per hour, Bertuzzi’s production lines are suited for high-volume production.

Price: Due to their advanced technology and premium materials, Bertuzzi’s equipment is priced between $800,000 to $2,000,000. However, their systems have lower maintenance costs over the long term, making them a solid investment.

Technical Support: Bertuzzi offers global technical support, with specialized after-sales teams that ensure equipment remains operational through regular maintenance and upgrades. Their customers benefit from periodic inspections and ongoing technical advice.

Summary: Bertuzzi is the best choice for large-scale food processors requiring high-efficiency systems and top-quality production. The equipment’s advanced features and robust design justify its premium pricing for long-term productivity.

4. Brand D: JBT Corporation

JBT Corporation, a well-established American manufacturer, excels in providing highly automated tomato paste production lines equipped with the latest technology.

Performance: JBT systems come equipped with advanced smart control systems that optimize the production process using big data analytics. With a capacity of 20-30 tons per hour, their equipment is ideal for continuous large-scale production. The high degree of automation reduces human intervention and maximizes efficiency.

Price: JBT’s equipment is among the most expensive, with prices ranging from $1,000,000 to $3,000,000. However, the system’s extended service life and ability to reduce operational costs make it a worthwhile investment for many companies.

Technical Support: JBT offers global technical support, including on-site maintenance, regular equipment upgrades, and expert troubleshooting. Their team ensures equipment operates smoothly through every phase of production.

Summary: JBT is the right choice for large-scale businesses that seek high levels of automation and production optimization. While expensive, the equipment’s smart technology and support make it ideal for improving productivity and reducing labor costs.

III. How to Choose the Right Tomato Paste Production Line

1. Consider Production Scale

Businesses should select equipment based on their production scale. For small to medium-sized enterprises, Shanghai Chase provides affordable yet flexible equipment, while larger enterprises may find Goma or Bertuzzi more suitable for large-scale operations.

2. Budget

The budget will play a significant role in selecting equipment. Companies with substantial financial resources may opt for high-end brands like JBT or Bertuzzi, while those with limited budgets can turn to more economical options like Shanghai Chase.

3. Level of Automation

The level of automation directly affects production efficiency and labor costs. If automation is a priority, JBT Corporation’s smart systems offer the most advanced solutions, while companies with smaller scale operations may find that Shanghai Chase provides adequate flexibility and performance.

4. Technical Support

It’s essential to select brands that offer reliable technical support and after-sales service to ensure minimal downtime in the production process. Global support networks like those from Goma or Bertuzzi are critical for large operations, while regional support from companies like Shanghai Chase is sufficient for local production.

IV. Conclusion

Different brands of tomato paste production line equipment offer distinct advantages based on production needs, budget, and technical requirements. Goma Machinery, Shanghai Chase, Bertuzzi Food Processing, and JBT Corporation all provide top-tier equipment, but the choice ultimately depends on each company’s specific circumstances.

To summarize:

Goma Machinery: Ideal for large operations with a focus on stability and long-term efficiency.

Shanghai Chase: Best for small to medium enterprises looking for cost-effective solutions.

Bertuzzi: Suited for businesses that prioritize top-quality production and long-term performance.

JBT Corporation: Best for large-scale operations that require high levels of automation and smart technology.

By considering production capacity, budget, automation needs, and technical support, businesses can make informed decisions to optimize their tomato paste production processes.

Must-Read Blogs For Chain Restaurants Owner

Portable Flake Ice Machine

Portable Flake Ice Machine Pelmeni Making Machine

Pelmeni Making Machine

Ready to Get Started?