China Tomato Paste Machine

Introduction: The Rise of China’s Tomato Paste Machines

The global food processing industry has undergone significant transformations in the last few decades, with technological advancements becoming a driving force in reshaping production lines. Among the key players in this evolution, China has emerged as a dominant force in manufacturing tomato paste machines. This surge in technological innovation has positioned China not only as a leader in the production of tomato paste but also as a critical supplier of the machinery that makes it all possible. With growing demand for processed tomato products across the world, Chinese manufacturers have capitalized on the need for efficient, high-capacity equipment capable of meeting the stringent standards required in the food industry.

Overview of China’s Influence in the Global Tomato Paste Market

China is now the world’s largest exporter of tomato paste, dominating over 40% of the global market share. The country’s strategic positioning, vast agricultural resources, and unparalleled manufacturing capabilities have allowed it to rise to prominence in the tomato paste industry. What often goes unnoticed, however, is the machinery behind this immense production. Chinese manufacturers have played a pivotal role in shaping the industry, creating state-of-the-art tomato paste machines that have revolutionized the entire production process. These machines not only increase output but also ensure consistency and quality, key factors that have elevated China’s reputation as a top supplier of both products and processing technology.

Why Tomato Paste Machines Are Critical in Modern Food Production

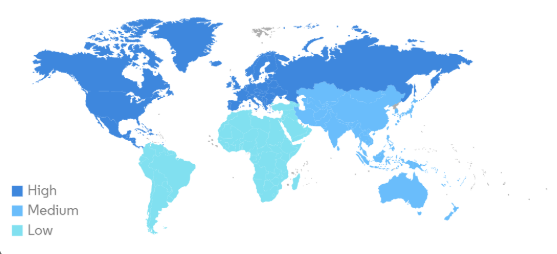

In modern food production, automation is crucial. The days of manual, labor-intensive processing are long gone. Tomato paste machines, designed for high efficiency and precision, ensure a streamlined production process that reduces waste, labor costs, and time. With a growing global demand for processed tomato products, especially in regions like Europe, the Middle East, and North America, automated tomato paste machines are an essential tool for businesses looking to stay competitive. These machines facilitate the rapid, large-scale production of tomato paste, helping manufacturers meet the increasing needs of the market without compromising on quality.

The Global Demand for Tomato Paste and Processing Machinery

The global demand for tomato paste has soared due to the growing popularity of products such as sauces, soups, and ready-to-eat meals, all of which rely heavily on tomato paste as a core ingredient. As more consumers seek convenient and processed food options, the need for tomato paste production machinery becomes even more pressing. Processing equipment, specifically those that allow for large-scale production, are a necessary investment for companies seeking to stay ahead of the market curve. In this climate, China has effectively positioned itself as both a supplier of raw tomato paste and the machinery that ensures its efficient and consistent production.

Market Growth and the Shift to Automated Solutions

The rise in demand for processed food products has spurred the growth of the tomato paste market, compelling manufacturers to adopt more advanced, automated solutions. Automation in food production is no longer a luxury but a necessity. As businesses scale up production to meet the global demand, automation reduces the risk of human error, increases throughput, and ensures that high-quality standards are maintained. Moreover, as labor costs rise and the need for faster production increases, automated tomato paste machines are becoming the standard in the industry. Chinese manufacturers have capitalized on this shift by developing machines that offer superior efficiency and consistency at a fraction of the cost of European or American alternatives.

How Tomato Paste Machines Meet the Demand for Efficiency and Quality

Tomato paste machines are engineered to handle large volumes of tomatoes while maintaining quality and flavor integrity. By automating key steps such as sorting, washing, crushing, cooking, and packaging, these machines eliminate human errors that can affect the taste, texture, and overall quality of the paste. Moreover, advanced systems built into the machines ensure that the paste’s consistency and purity are maintained, even in high-volume production settings. In an industry where quality assurance is critical, these machines provide a reliable, repeatable solution that enhances the final product’s appeal in the marketplace.

Understanding Tomato Paste Machines

What is a Tomato Paste Machine?

A tomato paste machine is a specialized piece of equipment designed to process raw tomatoes into concentrated paste. This paste is then used as a base ingredient in various products such as sauces, soups, ketchup, and more. The machine typically integrates several functions such as washing, crushing, cooking, and concentrating, to produce a uniform, high-quality product. By automating the entire process, tomato paste machines eliminate the need for manual labor, offering a more efficient and hygienic way of producing paste in large quantities.

The Key Components of a Tomato Paste Production Line

The tomato paste production line is an intricate assembly of machinery that works together to convert fresh tomatoes into paste. Key components of the production line include:

- Washing and Sorting Machines: These ensure that tomatoes are thoroughly cleaned and sorted for optimal quality.

- Crushers and Blenders: These machines break down the tomatoes into pulp, preparing them for the next steps in the process.

- Cookers: These use heat to concentrate the tomato pulp, reducing water content and enhancing the paste’s flavor.

- Filter and Separator Systems: These machines remove seeds and skins from the paste, ensuring a smooth, consistent texture.

- Packaging Machines: Once the paste is ready, these machines package it into containers for distribution.

How Tomato Paste Machines Function: Step-by-Step Process

Tomato paste machines follow a systematic, multi-stage process:

- Sorting and Washing: Raw tomatoes are sorted to remove any undesirable items and washed to ensure they are free from dirt and contaminants.

- Crushing: The tomatoes are then crushed into a pulp to extract their juice and flesh.

- Cooking and Concentrating: The pulp is heated to remove excess water, concentrating the flavor and creating the thick paste.

- Filtering and Refining: Any seeds, skins, or other impurities are filtered out to leave only the smooth, rich paste.

- Packaging: The paste is cooled and packaged into jars, cans, or pouches, depending on the desired product format.

Types of Tomato Paste Machines Manufactured in China

Automatic Tomato Paste Machines

Automatic tomato paste machines are fully integrated systems that handle the entire production process from start to finish. These machines are designed for large-scale operations where speed and consistency are critical. With minimal human intervention, they offer high throughput and are ideal for manufacturers looking to meet the global demand for tomato paste. Automation also ensures precise control over variables such as temperature, pressure, and cooking time, all of which are crucial for producing high-quality paste.

Semi-Automatic Machines: Balancing Cost and Efficiency

For smaller-scale operations, semi-automatic tomato paste machines offer a balance between cost and performance. These machines automate key stages of the process but may still require some manual oversight. Semi-automatic machines are particularly suited to mid-tier production facilities that need to maintain flexibility without committing to the full investment of a completely automated system. They provide a viable solution for businesses aiming to scale their operations gradually.

Small-Scale vs. Large-Scale Tomato Paste Machines

Small-scale machines are typically used by artisanal producers or smaller factories, offering the flexibility to produce batches of tomato paste with a more hands-on approach. These machines, while not as fast or automated, allow for greater control over the final product. On the other hand, large-scale machines are used by major manufacturers and are capable of producing vast quantities of tomato paste in a fraction of the time. These machines often come equipped with advanced features like programmable logic controllers (PLCs) and real-time monitoring systems to ensure optimal performance.

Technology and Innovation in China's Tomato Paste Machines

Advances in Automation and Robotics

Chinese manufacturers have been at the forefront of integrating advanced automation and robotics into tomato paste production. By utilizing robotic arms, conveyor systems, and AI-driven software, these machines can perform repetitive tasks with high precision, reducing the margin for error and enhancing overall productivity. This level of automation allows companies to scale production effortlessly while maintaining consistent quality.

Integration of AI and IoT in Tomato Paste Production

Artificial intelligence (AI) and the Internet of Things (IoT) are increasingly being integrated into the design of tomato paste machines. These technologies enable real-time monitoring of production conditions, ensuring that every batch of paste is made to exact specifications. AI can predict maintenance needs, optimize energy consumption, and detect potential issues before they cause downtime, offering a level of operational intelligence that has transformed the industry.

Energy Efficiency and Sustainability Innovations

As environmental concerns continue to rise, Chinese manufacturers are innovating to create more energy-efficient and sustainable tomato paste machines. Modern machines are designed to minimize water usage, reduce energy consumption, and lower waste output. By adopting green technologies, such as solar power and energy recovery systems, these machines are helping tomato paste producers lower their carbon footprint while maintaining high levels of productivity.

The Manufacturing Process: From Fresh Tomatoes to Paste

Sorting and Washing: Ensuring Quality and Cleanliness

The first step in tomato paste production is sorting and washing the raw tomatoes. Sorting ensures that only ripe, high-quality tomatoes are used in the production process, while washing removes dirt, pesticides, and other impurities. The cleanliness of the tomatoes is essential, as any contaminants could compromise the final product’s quality.

Crushing and Extraction: Maximizing Yield and Flavor

Once the tomatoes are cleaned, they are crushed to extract their juice and flesh. Modern crushing machines use precise mechanical processes that maximize yield while minimizing waste. The goal is to produce a smooth, consistent pulp that retains the maximum flavor and nutritional value.

Cooking and Concentrating: Achieving the Perfect Consistency

The next step is cooking the pulp to reduce its water content, thereby concentrating the flavor and creating the thick paste that is characteristic of high-quality tomato paste. Cooking times and temperatures are carefully controlled to preserve the natural taste and color of the tomatoes.

Cooling, Packaging, and Storage: Preserving Freshness and Shelf Life

Once the paste is concentrated, it is cooled to preserve its freshness and prevent spoilage. After cooling, the paste is packaged in containers for storage and distribution. The packaging process is crucial for maintaining the shelf life of the paste, ensuring that it reaches consumers in optimal condition.

Advantages of Using Chinese-Made Tomato Paste Machines

Cost-Effectiveness and High ROI

One of the most compelling reasons to choose Chinese-made tomato paste machines is their cost-effectiveness. While still maintaining high standards of quality and efficiency, these machines are often more affordable than their Western counterparts. This lower initial investment results in a quicker return on investment (ROI), especially for businesses looking to scale production without taking on substantial debt.

Durability and Long-Term Performance

Chinese manufacturers are known for producing durable machines built to withstand the rigors of continuous, high-volume production. These machines are designed with longevity in mind, ensuring that manufacturers can rely on them for years without frequent repairs or replacements.

Customization Options for Different Production Needs

Another advantage of Chinese-made machines is their flexibility. Manufacturers can customize machines based on their specific production requirements, whether that involves adjusting capacity, incorporating additional features, or adapting to different types of packaging.

Support and After-Sales Service

Chinese manufacturers often provide extensive after-sales support, including installation, training, and ongoing maintenance services. With an established network of service technicians, these suppliers ensure that customers receive the necessary assistance to keep their production lines running smoothly.

Factors to Consider When Buying a Tomato Paste Machine from China

Machine Capacity and Output Requirements

Before investing in a tomato paste machine, it is essential to assess the production scale and required output. Understanding the machine’s capacity ensures that it can handle the volume of tomatoes required to meet production demands.

Space and Facility Requirements

Tomato paste machines vary in size and complexity. Companies must ensure that they have the space and infrastructure to accommodate the machines they are purchasing, including considerations for electricity, water, and other logistical aspects.

Compliance with International Standards and Certifications

In an increasingly globalized marketplace, compliance with international food safety standards is paramount. Buyers should verify that the tomato paste machines meet necessary regulatory certifications such as CE, ISO, or FDA approvals, ensuring that they can export products without compliance issues.

Understanding Warranty and Maintenance Plans

A comprehensive warranty and maintenance plan is essential when purchasing a tomato paste machine. Warranties typically cover repairs, replacements, and technical support, while maintenance plans ensure that the machines continue to operate at peak performance throughout their lifecycle.

Top Manufacturers of Tomato Paste Machines in China

Overview of Leading Brands in the Chinese Market

China is home to several top manufacturers of tomato paste machines, each specializing in different aspects of the production process. Brands such as Sichuan Yibin, Jinan XINTONG, and Zhejiang Jiacheng are recognized for their quality machinery and innovative technology. These manufacturers serve not only domestic markets but also export their products worldwide.

Key Manufacturers and Their Specialties

Some manufacturers specialize in fully automated systems, while others focus on semi-automatic machines or equipment tailored for smaller-scale operations. Additionally, some companies offer turnkey solutions that include the entire production line, while others may focus on specific components like crushers or packaging systems.

How to Choose a Reliable Supplier for Tomato Paste Machines

Choosing a reliable supplier involves researching the company’s reputation, product quality, and customer service. Buyers should request references from existing customers, ask about warranty terms, and inquire about the company’s experience in international exports.

Quality Control: Ensuring Consistent Tomato Paste Production

The Role of Quality Control in Tomato Paste Production

Quality control is an essential part of tomato paste production. A minor defect in any stage of the process, whether during washing, crushing, or cooking, can significantly affect the taste, texture, and appearance of the paste. Quality control systems built into modern tomato paste machines ensure that every batch is produced according to the highest standards.

Features of High-Quality Tomato Paste Machines

High-quality machines are designed to optimize efficiency, consistency, and safety. Features such as automatic temperature control, advanced filtration systems, and real-time monitoring ensure that the production process remains within the desired parameters.

How to Identify and Avoid Common Manufacturing Defects

Common manufacturing defects can include issues like improper sealing, faulty heating elements, or inadequate filtration. Buyers should inspect machines for signs of subpar workmanship and request demonstrations or samples before committing to a purchase.

Cost Analysis: Investing in a Tomato Paste Machine

Initial Investment and Setup Costs

The cost of purchasing a tomato paste machine includes not only the price of the equipment but also installation, training, and any required facility modifications. Understanding the full scope of initial investments is critical for budgeting and planning purposes.

Operational Costs and Long-Term Savings

While Chinese-made tomato paste machines offer a more affordable upfront cost, it is important to consider ongoing operational expenses such as electricity, water, and maintenance. However, these machines often result in long-term savings due to their efficiency and durability.

How to Calculate ROI in Tomato Paste Production

The ROI of a tomato paste machine can be calculated by comparing the initial investment with the increased output and reduced operational costs over time. Manufacturers should track key metrics such as production speed, energy consumption, and labor savings to evaluate the overall return.

Exporting Tomato Paste Machines from China: What You Need to Know

Key Considerations for International Buyers

International buyers should ensure that the machines comply with their country’s import regulations and food safety standards. It is also important to evaluate shipping costs and timelines when considering purchasing from overseas.

Import Regulations and Customs Procedures

Import regulations vary from country to country, and buyers should be familiar with the specific requirements for importing food processing equipment. This may include certifications, documentation, and possible tariffs.

Shipping and Logistics: Ensuring Safe Delivery

Shipping large, complex machines across borders can be challenging. Buyers must work with reliable logistics partners who can handle customs paperwork, provide insurance, and ensure safe delivery.

Challenges in Tomato Paste Machine Production

Material Sourcing and Supply Chain Constraints

The production of tomato paste machines relies on a steady supply of high-quality materials such as stainless steel and electrical components. Supply chain disruptions, whether due to global events or local shortages, can impact production timelines and costs.

Adapting to Changing Global Standards and Regulations

As global food safety standards evolve, manufacturers must adapt their machines to comply with new regulations. This requires continuous innovation and close attention to international market trends.

Overcoming Technical Difficulties and Downtime

Even the most reliable machines may experience technical difficulties, leading to downtime. Having a proactive maintenance plan in place helps mitigate the risk of unexpected malfunctions and ensures smooth, uninterrupted production.

The Future of Tomato Paste Machine Technology

Emerging Trends in Automation and AI

The future of tomato paste production lies in even more advanced automation and artificial intelligence. These technologies will allow machines to become smarter, more efficient, and better at predicting and adjusting for variances in production conditions.

How Sustainability Will Shape the Future of Tomato Paste Production

Sustainability will continue to be a driving force behind future innovations in tomato paste machines. This includes reducing energy usage, minimizing waste, and sourcing raw materials more responsibly.

China’s Role in the Global Evolution of Food Processing Technology

China’s role in the food processing industry will continue to grow as it develops new technologies and solutions for processing equipment. As the global demand for food products rises, Chinese manufacturers will be at the forefront of producing the machinery needed to meet this demand.

Case Studies: Success Stories from Tomato Paste Manufacturers Using Chinese Machines

Streamlining Production in Large-Scale Factories

Many large-scale tomato paste producers have leveraged Chinese-made machines to increase production capacity and improve efficiency. These success stories highlight the machines’ ability to meet the demands of high-volume operations while maintaining product consistency.

Enhancing Quality Control in Small-Scale Operations

Small-scale tomato paste producers have also benefited from Chinese machines, especially semi-automatic models. These systems provide smaller businesses with the ability to scale production while keeping operational costs manageable.

How Chinese Machines Have Helped Companies Expand Their Reach

The scalability and adaptability of Chinese-made tomato paste machines have allowed businesses to expand into new markets. By increasing production capacity without compromising quality, companies have been able to meet the needs of a growing global customer base.

Conclusion: The Strategic Advantage of Investing in Chinese Tomato Paste Machines

China’s tomato paste machines offer a competitive edge for businesses looking to improve production efficiency, reduce costs, and enhance product quality. As the demand for processed food products continues to grow, investing in Chinese-made machinery presents a strategic opportunity to capitalize on global market trends. With continued innovation and advancements in automation, China will remain a key player in the evolution of the food processing industry.

Next : Top 10 Meat Cutting Machine Manufacturers In China

Must-Read Blogs For Chain Restaurants Owner

Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Tomato Paste Production Line

Tomato Paste Production Line

Ready to Get Started?