Automatic Chicken Cutting Machine Price: A Comprehensive Guide to Understanding Costs and Value

Introduction

In today’s fast-paced food production environment, efficiency is everything. The automatic chicken cutting machine stands at the heart of this transformation, automating a process that once required tedious manual labor. As demand for meat products rises, so does the need for more advanced machinery to meet production goals. The price of an automatic chicken cutting machine can vary widely based on several factors, making it essential for businesses to fully understand what influences these costs. This guide explores not only the price but also the value these machines provide and how to choose the right one for your business.

What is an Automatic Chicken Cutting Machine?

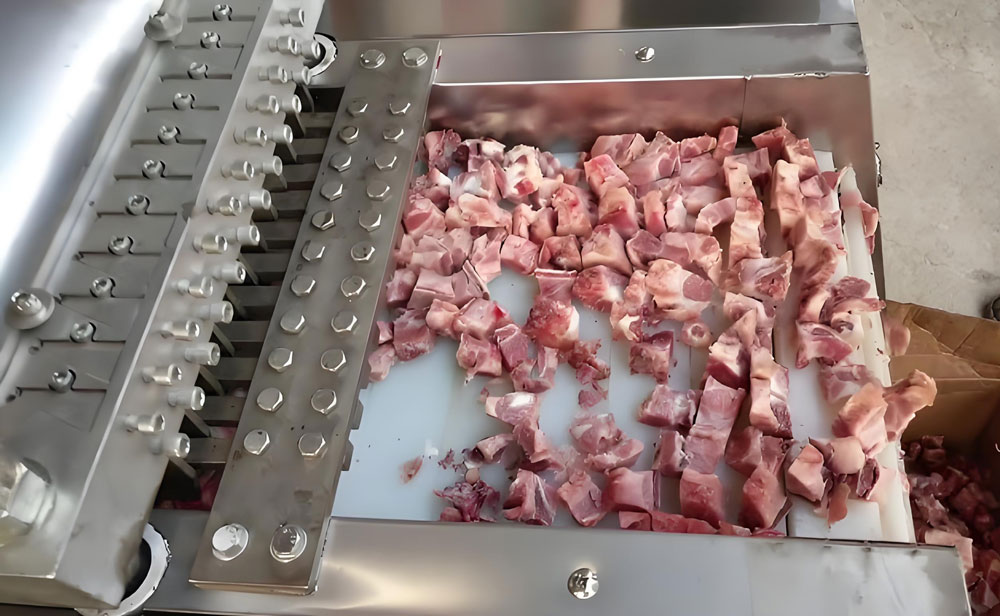

An automatic chicken cutting machine is an advanced piece of equipment designed to process chicken into various cuts such as wings, thighs, breasts, and even whole birds. These machines automate the labor-intensive process of portioning and cutting, reducing the need for manual labor and increasing processing speed. With precise and consistent cuts, these machines help improve production efficiency while maintaining high-quality output. They are commonly used in both small butcher shops and large-scale industrial facilities, where high-volume meat processing is required.

Why is the Price of Automatic Chicken Cutting Machines Important?

For any business investing in an automatic chicken cutting machine, price isn’t just about the initial outlay. It’s about understanding the long-term value the machine brings in terms of efficiency, labor savings, and overall productivity. Prices can range from a few thousand to tens of thousands of dollars, depending on factors like automation level, machine capacity, and brand. It is crucial to evaluate not just the upfront cost, but how that investment will impact the bottom line over time—whether through reduced labor costs, increased throughput, or less waste.

Factors Influencing the Price of Automatic Chicken Cutting Machines

Machine Capacity: Size and Output Matter

The capacity of an automatic chicken cutting machine plays a major role in determining its price. Smaller machines that process fewer chickens per hour tend to cost less, while larger machines designed to handle high-volume production come with a higher price tag. The output capacity, often measured in pounds per hour or chickens processed per minute, is a crucial factor. Businesses with high demand for chicken processing will need to invest in a machine with greater capacity to ensure they can meet production targets.

Material Quality: Durability and Performance

The materials used in the construction of the machine directly affect its durability and performance. Machines made from high-grade stainless steel, for example, not only last longer but are also more resistant to corrosion and easier to clean, making them ideal for food processing environments. Higher-quality materials increase manufacturing costs, which is reflected in the price of the machine. However, these machines often offer better long-term value due to their reliability and minimal maintenance requirements.

Automation Level: The Impact of Features on Price

Automatic chicken cutting machines come with varying levels of automation. Basic models may only automate the cutting process, while more advanced machines include features like automatic sorting, weighing, and packaging. Machines with greater automation typically have higher upfront costs but can offer significant savings in labor and time. Features such as automated hygiene cleaning cycles and remote monitoring also add to the price but improve efficiency and reduce operational complexity.

Brand Reputation and Manufacturer Influence

Just like in any industry, the reputation of the brand plays a significant role in the pricing of automatic chicken cutting machines. Well-established manufacturers often charge a premium for their products due to their proven track record of reliability, quality, and customer service. Lesser-known brands may offer lower prices but could lack the same level of support or dependability. Choosing a reputable brand can provide peace of mind and reduce the risk of unexpected costs due to machine failures or poor performance.

Technological Advancements: How Modern Features Affect Pricing

As with all technology, advancements in automation and precision cutting techniques can increase the price of a chicken cutting machine. Newer models may incorporate cutting-edge technologies like AI-driven adjustment systems, faster processing speeds, and enhanced safety features. These technologies improve efficiency and reduce human error, but they also come with higher costs. While the initial investment might be steeper, businesses can expect to see a quicker return on investment (ROI) due to the enhanced productivity these machines offer.

Customization Options: Tailored Machines and Price Variations

Customization is another factor that influences price. Some businesses may require specific features or specialized cutting configurations, such as machines designed to cut chicken in certain ways for gourmet or international markets. Custom-built machines or those with unique configurations typically come at a premium. While the extra features can increase the cost, they can also cater precisely to a business’s operational needs, allowing for more efficient and specialized production.

Types of Automatic Chicken Cutting Machines

Basic Models vs. Advanced Models

Basic models of chicken cutting machines typically perform simple cuts such as breast and thigh portions, with fewer automation features and lower processing speeds. These machines are generally more affordable, making them suitable for small businesses with modest processing needs. In contrast, advanced models are designed for larger operations and can handle a wider variety of cuts, including precise wing and leg separation, with faster processing speeds and more automation features.

Small-Scale Machines for Local Butchers

Small-scale machines are designed to cater to the needs of local butchers or small processing units. These machines are compact, more affordable, and offer basic cutting functionalities. They are ideal for businesses that handle lower volumes of meat but still require a high level of accuracy in their cuts. The price of these machines reflects their smaller scale and simpler operations.

Industrial-Grade Machines for Large-Scale Operations

Industrial-grade machines are built to handle high-volume production, processing hundreds or even thousands of chickens per hour. These machines are equipped with advanced features like automated sorting, packaging, and hygiene cleaning, making them ideal for large-scale processing plants. While the initial cost is considerably higher, the machine’s efficiency in processing large quantities justifies the investment for large operations looking to maximize productivity.

Specialized Machines for Different Cuts: Whole, Wings, Thighs, etc.

Specialized machines focus on specific cuts of chicken. For instance, some machines are optimized for deboning, while others focus on slicing wings or cutting whole birds into precise portions. These specialized machines are designed to meet the needs of different market segments, such as restaurants or grocery stores that require specific cuts. Depending on the complexity of the features, the price of these machines may vary.

Mobile and Compact Machines for On-the-Go Processing

Mobile and compact chicken cutting machines are becoming increasingly popular for businesses that need to process chicken in various locations. These machines are smaller, lightweight, and often designed to be used in mobile processing units, such as food trucks or remote processing plants. While they offer portability, they typically come with a more affordable price point compared to large industrial machines.

Understanding the Price Range of Automatic Chicken Cutting Machines

Entry-Level Machines: What You Can Expect

Entry-level automatic chicken cutting machines are typically priced lower, ranging from a few thousand dollars to around $10,000. These machines generally offer basic functionality with lower processing speeds and simpler automation. They are ideal for smaller businesses or startups looking to invest in automation without a heavy financial commitment.

Mid-Range Machines: Balancing Cost and Features

Mid-range machines strike a balance between affordability and advanced features. Priced between $10,000 and $30,000, these machines offer more automation and higher processing speeds than entry-level models. Businesses looking to scale their operations or increase production efficiency without breaking the bank often find these machines to be the best value.

High-End Machines: Premium Features and Capabilities

High-end automatic chicken cutting machines can cost upwards of $30,000, depending on the features and technology integrated into the system. These machines offer the highest levels of automation, including features like real-time performance tracking, remote monitoring, and customizable cutting options. They are ideal for large processing plants or operations with very high-volume needs.

Cost Comparison Between Manual vs. Automatic Machines

While manual cutting machines or labor-intensive methods may seem more affordable upfront, they can result in higher long-term costs due to increased labor requirements, slower processing speeds, and potential for human error. On the other hand, automatic chicken cutting machines, though more expensive initially, reduce labor costs, increase throughput, and improve consistency, making them a more cost-effective choice in the long run.

The Role of Energy Efficiency in Pricing

Energy-Saving Features and Long-Term Cost Benefits

Energy-efficient automatic chicken cutting machines may have a higher upfront cost, but their long-term savings can be significant. Machines with features like variable-speed motors, energy-efficient blades, and automatic shutdown modes help reduce energy consumption, leading to lower operating costs. Over time, the savings on utility bills can offset the initial price difference, making energy-efficient machines a wise investment.

How Energy Efficiency Impacts Operational Costs

Energy consumption is a key operational cost for any meat processing facility. Machines that require less energy to operate can help businesses reduce their carbon footprint while keeping costs manageable. By choosing energy-efficient equipment, businesses can reduce their reliance on costly electricity, helping to balance their operational budget and make a more sustainable choice.

How to Calculate the Return on Investment (ROI) for Automatic Chicken Cutting Machines

Initial Investment vs. Long-Term Savings

When purchasing an automatic chicken cutting machine, businesses must consider not just the initial investment but also the potential savings over time. A more expensive machine with higher automation may cost more upfront but could save significantly in labor costs, reduce waste, and improve production speed, leading to a faster return on investment (ROI). Analyzing the machine’s ability to reduce operational costs and improve efficiency is essential to understanding its long-term value.

Increased Efficiency: How Faster Production Reduces Costs

Faster production rates directly translate to higher output, enabling businesses to process more chickens in less time. Increased efficiency often results in reduced labor needs and better overall workflow, which can reduce operational bottlenecks and increase profitability. The more a business can streamline its processes, the greater the potential ROI.

Labor Cost Reduction: The Savings from Automation

Automation offers a significant advantage in reducing labor costs. By automating the chicken cutting process, businesses can reduce the number of workers needed, lower wages, and eliminate potential costs associated with labor shortages, absenteeism, or worker injuries. Over time, these savings can make the higher price of an automatic cutting machine seem like a small price to pay for the financial benefits it provides.

Additional Costs to Consider When Buying an Automatic Chicken Cutting Machine

Installation Fees and Setup Costs

In addition to the purchase price, businesses should factor in installation fees and setup costs. These costs include transportation, assembly, calibration, and any modifications needed to integrate the machine into existing workflows. Installation fees can vary, so it’s important to inquire about these additional costs before making a purchase.

Maintenance and Repair Costs Over Time

While automatic chicken cutting machines are designed for durability, regular maintenance is necessary to keep them running efficiently. Maintenance costs can include routine cleaning, replacing worn-out parts, and conducting safety inspections. Some manufacturers offer maintenance packages that can help mitigate these ongoing expenses, so it’s essential to plan for these costs in the long-term budget.

Spare Parts and Consumables: What You Need to Know

Certain parts of the machine, such as blades and belts, will wear out over time and need replacing. Spare parts and consumables can add to the overall cost of ownership. Some machines may require specific parts that are more expensive, so it's crucial to understand the ongoing costs of keeping the machine in good working order.

Training for Operators: Adding to the Initial Investment

Training is another often-overlooked cost when purchasing an automatic chicken cutting machine. Operators need to be properly trained to use the machine safely and efficiently, which may involve additional expenses. Depending on the complexity of the machine, training programs may be provided by the manufacturer or require external training services. This cost should be factored into the overall investment.

How to Choose the Right Automatic Chicken Cutting Machine for Your Business

Analyzing Your Production Needs and Volume

Before purchasing an automatic chicken cutting machine, businesses must carefully assess their production needs and volume. Machines come in various sizes and capacities, so it’s essential to choose one that can handle your expected throughput without over- or under-performing.

Understanding Your Budget and Price Expectations

Establishing a clear budget is crucial. The price range for automatic chicken cutting machines can vary significantly depending on the features and specifications. Understanding your price expectations will help you narrow down the options and choose the best machine within your financial parameters.

Balancing Features, Quality, and Cost

While it’s tempting to focus solely on the price, it’s essential to consider the features, quality, and long-term value of the machine. Balancing these factors ensures that you get a machine that meets your operational needs without compromising quality or budget.

The Importance of After-Sales Support and Warranty

A solid warranty and reliable after-sales support are critical factors to consider when purchasing an automatic chicken cutting machine. These services can save businesses money on repairs and maintenance and provide peace of mind in case the machine experiences technical issues.

How to Negotiate the Best Price for an Automatic Chicken Cutting Machine

Tips for Getting Discounts from Manufacturers and Suppliers

Negotiating is an important skill when purchasing an automatic chicken cutting machine. Many suppliers offer discounts for bulk orders or long-term contracts. Don’t hesitate to ask for a price reduction, especially if you’re purchasing more than one machine or committing to a long-term relationship with the supplier.

When to Buy: Seasonal Deals and Offers

Timing your purchase can also impact the price you pay for the machine. Many manufacturers offer seasonal promotions or discounts during slower sales periods. Shopping around during these times can help you secure a better deal.

Leveraging Bulk Orders for Better Pricing

If your business needs multiple machines or plans to expand its operations, leveraging bulk orders can significantly reduce the overall cost. Suppliers are often willing to offer discounts on large purchases, helping businesses save money on a more substantial investment.

Top Manufacturers and Brands of Automatic Chicken Cutting Machines

Leading Global Brands: Who’s Dominating the Market?

Some of the world’s leading manufacturers in the chicken cutting machine industry include [insert global names]. These companies have established themselves with high-quality products and strong reputations for reliability and customer support. While they may offer higher prices, their machines tend to come with superior features and longer lifespans.

Up-and-Coming Brands Offering Competitive Prices

While established brands dominate the industry, new manufacturers often offer competitive prices with similar or innovative features. These up-and-coming brands can be a great option for businesses looking to save money while still getting a high-quality product.

Local vs. International Manufacturers: Which is More Cost-Effective?

When choosing a manufacturer, businesses should weigh the pros and cons of local versus international suppliers. While international brands may offer cutting-edge technology, local manufacturers can often provide lower shipping costs, quicker delivery times, and better after-sales support.

Where to Buy an Automatic Chicken Cutting Machine

Online Retailers and Marketplaces

Purchasing an automatic chicken cutting machine online through retailers like [insert names] can often provide a wider range of options and potentially lower prices. However, buyers should ensure they are purchasing from reputable sellers to avoid potential pitfalls.

Direct Manufacturer Purchases

Buying directly from the manufacturer often ensures the best price and access to customer support. Manufacturers may also offer customization options, extended warranties, or training programs when purchasing directly.

Local Dealers and Distributors

Local dealers or distributors provide the advantage of in-person consultations, which can be helpful when trying to assess your business’s specific needs. Working with a local distributor can also reduce shipping costs and ensure more personalized service.

Common Myths About Automatic Chicken Cutting Machine Prices

Are Expensive Machines Always Better?

Not necessarily. While expensive machines often come with more advanced features and higher capacities, businesses should evaluate their specific needs and find the best balance of features and cost.

The “You Get What You Pay For” Debate

While the saying "you get what you pay for" often holds true, it’s important to remember that price doesn’t always correlate with performance. Some mid-range machines may offer better value than high-end models, depending on the business's unique needs.

Can You Find High-Quality Machines at Lower Prices?

Yes, it’s possible to find quality machines at lower prices, especially from emerging brands or during promotional sales. Careful research and negotiations can help businesses get the best possible machine at an affordable price.

Customer Reviews and Feedback: What Do Users Say About Prices?

Real Experiences: Is the Machine Worth the Cost?

Customer reviews can provide valuable insights into whether an automatic chicken cutting machine offers good value for its price. Many users highlight the importance of machine reliability and long-term performance, making it essential to read reviews before making a purchase.

Price vs. Performance: What Buyers Are Saying

In the end, it’s the performance of the machine that determines whether the price is justified. Reviews often indicate whether the machine delivers on its promises in terms of speed, cutting accuracy, and ease of use.

The Future of Automatic Chicken Cutting Machines and Their Pricing Trends

How Innovations Will Impact Prices Moving Forward

With continued innovation in automation, energy efficiency, and AI-driven technology, the price of automatic chicken cutting machines may fluctuate. As demand for more sophisticated features grows, so will the sophistication of these machines, potentially driving prices higher.

Predictions for Price Reductions and Accessibility

As technology matures and becomes more widespread, prices may begin to decrease, making automatic chicken cutting machines more accessible to smaller businesses. Increased competition in the market could also drive down prices, making automation a more viable option for many.

Conclusion

Recap of Key Factors Affecting Price

The price of an automatic chicken cutting machine is influenced by several factors, including machine capacity, material quality, and automation features. Businesses must assess their specific needs to make an informed decision about the right machine for them.

Making the Right Investment for Your Business

Choosing the right machine isn’t just about price. It’s about finding the balance between cost, efficiency, and features that will help your business succeed in the long run.

Final Thoughts: Value Beyond the Price Tag

While the price is important, the value of an automatic chicken cutting machine goes far beyond the initial cost. By considering factors like efficiency, labor savings, and long-term ROI, businesses can make a smart investment that will continue to pay off for years to come.

Must-Read Blogs For Chain Restaurants Owner

Portable Flake Ice Machine

Portable Flake Ice Machine Pelmeni Making Machine

Pelmeni Making Machine

Ready to Get Started?