Application of Tomato Paste Production Line Equipment in Different Regions: Global Demand and the Impact of Cultural and Regulatory Differences

Tomato paste, a key product in the global food industry, is widely used across various countries and regions. Not only is tomato paste essential as a condiment, but it also serves as a base ingredient in numerous food processing applications. The demand for tomato paste production line equipment varies globally, with cultural and regulatory differences significantly impacting the design, functionality, and operation of this equipment. This article explores the demand for tomato paste production equipment in various global markets and analyzes how different countries’ regulations and cultural preferences influence equipment design and operational efficiency.

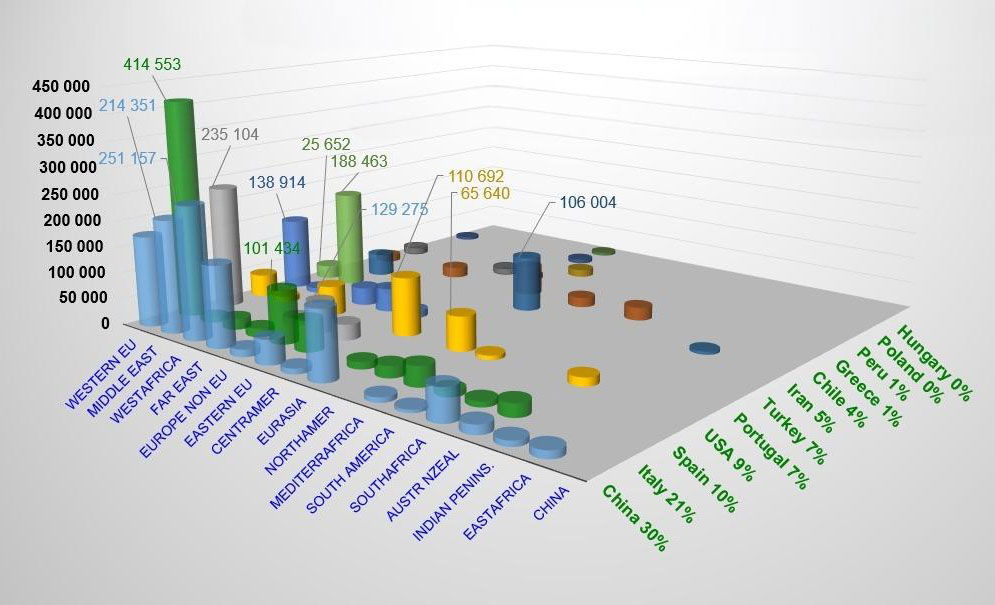

1. Global Demand for Tomato Paste Production Line Equipment

1.1 North American Market

In North America, particularly the United States and Canada, tomato paste is widely used in food industries, forming a base for soups, sauces, and pre-prepared meals. This region sees high demand for large-capacity, highly automated production equipment. In the United States, for example, food manufacturing is tightly regulated by the Food and Drug Administration (FDA), which mandates that production equipment adheres to strict food safety and hygiene standards. Using stainless steel to prevent bacterial growth is a basic requirement, especially in terms of cleaning and sanitization.

Furthermore, the growing trend towards organic and non-GMO foods in the U.S. has driven the need for production lines that can handle these specialized products. For instance, some production lines now incorporate separate modules to process organic tomato paste, catering to different market demands.

1.2 European Market

Europe, especially Italy and Spain, is another significant region for tomato paste production. Italy, with its rich history of tomato cultivation and demand for tomato paste, is an important market for tomato processing equipment. Italian food culture emphasizes preserving the natural flavor of tomatoes. As a result, equipment must not only offer efficient processing capabilities but also ensure that the tomatoes’ taste and texture are not compromised.

In addition to hygiene and efficiency, the European market places a higher emphasis on sustainability and environmental responsibility. European Union regulations require that food processing equipment be energy-efficient, and that wastewater and energy usage are optimized for minimal environmental impact.

To cater to the local market, European manufacturers design equipment that can handle various tomato varieties, from small cherry tomatoes to larger juicy tomatoes. Additionally, the stringent food safety standards in Europe push manufacturers to ensure that equipment is HACCP-compliant (Hazard Analysis Critical Control Points), reducing the risk of food contamination during production.

1.3 Asian Market

Asia, particularly China, represents an important emerging market for tomato paste production. China has become one of the largest producers and exporters of tomato paste globally. The demand for efficient production equipment is high, as Chinese manufacturers seek equipment that can maximize output at the lowest cost.

Due to the increasing stringency of food safety regulations, equipment must meet higher standards for sanitation, sterilization, and traceability. For export markets, Chinese manufacturers must ensure their equipment complies with international standards, such as the CE certification for the European Union or the FDA certification for the U.S. market.

In other Asian countries such as India and Southeast Asia, the demand for small- to medium-scale production lines is growing. For instance, in India, where tomato paste is widely used in local cuisine, there is an increasing demand for modular equipment that allows flexibility for small and medium enterprises to adjust production volumes according to market demand.

1.4 African Market

Africa’s tomato paste industry is still in its early stages, but countries like Nigeria and Ghana have started investing in local tomato paste production facilities, aiming to reduce dependency on imports. The demand for production equipment in these regions is primarily driven by cost-effectiveness and durability. Given the underdeveloped infrastructure and unstable power supply in some African regions, equipment needs to be highly durable and easy to maintain.

Moreover, African markets lean towards simplified equipment designs that can operate efficiently even in challenging environments. The growing middle class in Africa, coupled with government incentives to support local agriculture, has sparked interest in developing local tomato paste production capacity.

1.5 South American Market

South America, particularly Brazil and Argentina, has seen a gradual increase in local tomato paste production for both domestic consumption and export. Like North America and Europe, this region also leans towards automated, large-scale production lines to meet growing demand.

However, environmental regulations in South America, especially in Brazil, emphasize eco-friendly industrial processes. The Brazilian government enforces strict regulations on emissions and energy usage in industrial settings, pushing equipment manufacturers to design low-energy and low-emission production lines. Additionally, South American producers value versatility in their equipment, seeking machines that can switch between different tomato products such as puree, paste, and diced tomatoes.

2. The Impact of Cultural Differences on Equipment Design and Functionality

Cultural differences significantly influence the design and functionality of tomato paste production equipment. Consumer preferences, cooking habits, and taste demands vary across regions, driving different equipment requirements.

Italy: Italian cuisine emphasizes fresh, natural flavors. As a result, equipment must be designed to retain the authentic taste of tomatoes. This means that temperature control is critical in processing to avoid overcooking the tomatoes and losing flavor.

China: In contrast, the Chinese market places more emphasis on production efficiency and cost control. The equipment design is geared towards high-volume production, ensuring machines can process large quantities of tomatoes quickly while maintaining quality. The multi-functionality of the equipment is also in high demand as manufacturers seek to produce a variety of tomato products, such as paste, juice, and diced tomatoes, using a single line.

Africa: In regions like Africa, where cooking traditions often involve using tomato paste as a base for stews and sauces, there is a growing demand for equipment that can process different types of tomatoes, including fresh and dried tomatoes. Additionally, equipment must be robust enough to handle intermittent power supplies or harsh environmental conditions.

3. The Influence of Regulatory Differences on Equipment Design

3.1 Food Safety Standards

Different regions have varying food safety standards, each impacting the design of tomato paste production equipment.

United States (FDA Standards): In the U.S., food production equipment must comply with stringent sanitary design standards, particularly those regulated by the FDA. For example, all surfaces that come into contact with food must be made of non-reactive materials, such as stainless steel, to prevent contamination. Additionally, equipment must be easy to clean and disinfect to prevent the growth of harmful bacteria.

European Union (EU Directives): In Europe, food processing equipment must not only meet food safety requirements but also focus on sustainability. EU regulations mandate that food processing equipment is energy-efficient and minimizes wastewater discharge. To reduce carbon footprints, manufacturers must design equipment using energy-saving technologies like efficient motors and heat recovery systems.

China: China’s food safety regulations have become increasingly strict in recent years, especially for exported goods. Production equipment must meet both domestic and international food safety standards. For example, machines designed for export to the EU or the U.S. must comply with CE or FDA standards, respectively.

Africa: In Africa, food safety regulations are still developing. Many African nations are adopting international food safety standards, pushing local equipment manufacturers to improve hygiene and sanitation in their designs to meet both domestic and international market demands.

4. Choosing the Right Tomato Paste Production Line Equipment for Different Regions

When selecting tomato paste production line equipment for different regions, businesses need to consider several key factors:

Compliance with Local and International Regulations: Ensure that equipment meets local food safety regulations and can also comply with international standards if the company intends to export.

Capacity and Scalability: Depending on the market size, businesses may need scalable equipment that can adjust production volumes to accommodate market growth.

Customization: Equipment manufacturers should offer customizable solutions to meet specific regional needs. Whether it's handling different tomato varieties or adapting to local climates and infrastructure, customization is key.

Maintenance and Support: Equipment should come with technical support and spare parts supply, particularly in regions where maintenance resources are limited. Easy-to-maintain machines will ensure continuous production and minimize downtime.

Conclusion

The global demand for tomato paste production line equipment varies significantly based on regional requirements. The cultural and regulatory differences across markets like North America, Europe, Asia, Africa, and South America heavily influence equipment design, functionality, and compliance needs. Manufacturers looking to enter or expand into these markets must consider these factors carefully, ensuring their equipment can meet the unique demands of each region. With the right approach, businesses can optimize their tomato paste production processes, cater to local tastes and regulations, and ensure long-term success in the global market.

Must-Read Blogs For Chain Restaurants Owner

Portable Flake Ice Machine

Portable Flake Ice Machine Pelmeni Making Machine

Pelmeni Making Machine

Ready to Get Started?